As filed with the Securities and Exchange Commission on April 26, 2022

Registration Statement No. 333-____

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM S-1

REGISTRATION STATEMENT

UNDER

THE SECURITIES ACT OF 1933

*HEMOGLOBIN OXYGEN THERAPEUTICS LLC

(Exact name of registrant as specified in its charter)

| Delaware | 2834 | 46-5395558 | ||

(State or other jurisdiction of incorporation or organization) |

(Primary Standard Industrial Classification Code Number) |

(I.R.S. Employer Identification Number) |

674 Souder Road

Souderton, PA 18964

(267) 382-0064

(Address and telephone number of registrant’s principal executive offices)

Igor Serov

Chief Financial Officer

Hemoglobin Oxygen Therapeutics Inc.

674 Souder Road

Souderton, PA 18964

(267) 382-0064

(Name, address, including zip code, and telephone number, including area code, of agent for service)

Copies to:

David Ficksman, Esq. William P. Hubbard, Esq. TroyGould PC 1801 Century Park East, 16th Floor Los Angeles, CA 90067 Tel.: (310) 553-4441 |

Thomas J. Poletti, Esq. Veronica Lah, Esq. Manatt, Phelps & Phillips, LLP 695 Town Center Drive, 14th Floor Costa Mesa, CA 92646 Tel.: (714) 371-2500 |

Approximate date of commencement of proposed sale to the public:

As soon as practicable after the effective date of this registration statement becomes effective.

If any of the securities being registered on this Form are to be offered on a delayed or continuous basis pursuant to Rule 415 under the Securities Act of 1933 check the following box: ☒

If this Form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, please check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ☐

If this Form is a post-effective amendment filed pursuant to Rule 462(c) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ☐

If this Form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer ☐ | Accelerated filer ☐ | Non-accelerated filer ☒ | Smaller reporting company ☒ | |||

| Emerging growth company ☒ |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided to Section 7(a)(2)(B) of the Securities Act. ☐

* Prior to the closing of the offering to which this registration statement relates, Hemoglobin Oxygen Therapeutics LLC intends to convert into a Delaware corporation pursuant to a statutory conversion, and will change its name to Hemoglobin Oxygen Therapeutics Inc.

The registrant hereby amends this registration statement on such date or dates as may be necessary to delay its effective date until the registrant shall file a further amendment which specifically states that this registration statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933 or until the registration statement shall become effective on such date as the Securities and Exchange Commission, acting pursuant to said Section 8(a), may determine.

EXPLANATORY NOTE

Hemoglobin Oxygen Therapeutics LLC, the registrant whose name appears on the cover of this registration statement, is a Delaware limited liability company. Immediately prior to the closing of the offering to which this Registration Statement relates, Hemoglobin Oxygen Therapeutics LLC will convert into a Delaware corporation pursuant to a statutory conversion and change its name to Hemoglobin Oxygen Therapeutics Inc. as described in the section “Corporate Conversion” of the accompanying prospectus. As a result of the Corporate Conversion, all holders of membership interests and options exercisable for membership interests of Hemoglobin Oxygen Therapeutics LLC will become holders of shares of common stock and options to purchase common stock of Hemoglobin Oxygen Therapeutics Inc.

References in the accompanying prospectus to our capitalization and other matters pertaining to our common equity relate to the capitalization and common equity of Hemoglobin Oxygen Therapeutics Inc. after giving effect to the Corporate Conversion. However, the Financial Statements and summary historical financial data included in the accompanying prospectus are those of Hemoglobin Oxygen Therapeutics LLC and do not give effect to the Corporate Conversion. Shares of common stock of Hemoglobin Oxygen Therapeutics Inc. are being offered by this prospectus. The information in this preliminary prospectus is not complete and may be changed. These securities may not be sold until the registration statement filed with the Securities and Exchange Commission is effective. This preliminary prospectus is not an offer to sell, nor does it seek an offer to buy these securities in any jurisdiction where the offer or sale is not permitted.

| 2 |

The information in this preliminary prospectus is not complete and may be changed. These securities may not be sold until the registration statement filed with the Securities and Exchange Commission is effective. This preliminary prospectus is not an offer to sell, nor does it seek an offer to buy these securities in any jurisdiction where the offer or sale is not permitted.

Subject to Completion, dated April 26, 2022

PRELIMINARY PROSPECTUS

___________Shares of Common Stock

HEMOGLOBIN OXYGEN THERAPEUTICS LLC

Common Stock

|

This is an initial public offering of shares of our Common Stock. Prior to this offering, there has been no public market for our Common Stock. It is currently estimated that the initial public offering price per share will be between $___ and $___. We have applied for listing of our common stock on The Nasdaq Capital Market.

The actual public offering price per share will be determined between us and the underwriters at the time of pricing and may be at a discount to the current market price. Therefore, the assumed public offering price used throughout this prospectus may not be indicative of the final offering price.

Investing in our securities involves risks. See “Risk Factors” beginning on page 14.

Neither the Securities and Exchange Commission nor any state securities commission has approved or disapproved of these securities or determined if this prospectus is truthful or complete. Any representation to the contrary is a criminal offense.

| Per Share | Total | |||||||

| Price to the public | $ | $ | ||||||

| Underwriting discounts and commissions | $ | $ | ||||||

| Proceeds to us (before expenses)(1) | $ | $ | ||||||

| (1) | Does not include a non-accountable expense allowance equal to 1% of the gross proceeds of this offering payable to the underwriters, or the reimbursement of certain expenses of the underwriters. We refer you to “Underwriting” beginning on page 103 of this prospectus for additional information regarding underwriting compensation. |

We have granted the underwriters the option for a period of 45 days to purchase up to an additional ___ shares of common stock at the initial public offering price, less underwriting discounts and commissions, solely to cover over-allotments, if any.

The underwriter expects to deliver the shares on or about _____, 2022.

WestPark Capital, Inc.

Prospectus dated _______, 2022

| 3 |

TABLE OF CONTENTS

We have not, and the underwriters have not, authorized anyone to provide any information or to make any representations other than those contained in this prospectus or in any free writing prospectus prepared by or on behalf of us or to which we have referred you. We take no responsibility for and can provide no assurance as to the reliability of, any other information that others may give to you.

You should rely only on the information contained in this prospectus. No dealer, salesperson or other person is authorized to give information that is not contained in this prospectus. This prospectus is not an offer to sell nor is it seeking an offer to buy these securities in any jurisdiction where the offer or sale is not permitted. The selling stockholders are offering to sell and seeking offers to buy our common stock only in jurisdictions where offers and sales are permitted. The information in this prospectus is accurate only as of the date of this prospectus, regardless of the time of delivery of this prospectus or of any sale of these securities.

All trademarks, trade names and service marks appearing in this prospectus are the property of their respective owners. Solely for convenience, the trademarks and trade names in this prospectus are referred to without the ® and TM symbols, but such references should not be construed as any indicator that their respective owners will not assert, to the fullest extent under applicable law, their rights thereto.

| 4 |

The following summary highlights selected information contained elsewhere in this prospectus and is qualified in its entirety by the more detailed information and financial statements included elsewhere in this prospectus. It does not contain all the information that may be important to you and your investment decision. You should carefully read this entire prospectus, including the matters set forth under “Risk Factors,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” and our financial statements and related notes included elsewhere in this prospectus. In this prospectus, unless context requires otherwise, references to “we,” “us,” “our,” “HBO2 Therapeutics” or the “Company” refer prior to the Corporate Conversion discussed herein, to Hemoglobin Oxygen Therapeutics LLC, and after the Corporate Conversion, to Hemoglobin Oxygen Therapeutics Inc. References in this prospectus to our capitalization and other matters pertaining to our common equity relate to the capitalization and common equity of Hemoglobin Oxygen Therapeutics Inc. after giving effect to the Corporate Conversion. However, the Financial Statements and summary historical financial data included in this prospectus are those of Hemoglobin Oxygen Therapeutics LLC and do not give effect to the Corporate Conversion. The terms (A) “IPO Price” means the initial public offering price of the shares offered by means of this prospectus and (B) “Debt Conversion” refer to the conversion of the following principal amount of convertible indebtedness, plus interest accrued and unpaid interest where indicated below, immediately prior to the effective date of this offering assuming an IPO Price of $____per share, which is the midpoint of the price range set forth on the cover page of this prospectus, (i) $7,917,000 convertible into an estimated _____shares of common stock and (ii) $2,000,000 due on demand bearing no interest convertible into an estimated _____shares of common stock (a ___35% discount to the IPO Price). (iii) $486,000 due on demand bearing no interest convertible into an estimated _____shares of common stock (a 25% discount to the IPO Price).Unless otherwise indicated, all share and per share information gives effect to the “Debt Conversion”.

Company Overview

Certain Definitions

Throughout this document, the below terms shall have the following meanings:

| ● | “Indication” means a specific use of a product, such as the treatment of a specific condition or use in a specific procedure. | |

| ● | “Our product” means any product we have developed that has been approved for certain indications and markets. | |

| ● | “Product candidate” means any of our products that are under development, either for an initial approval, or development of an existing product for a new indication. |

Description of Our Operations, Principal Activities and Key Factors

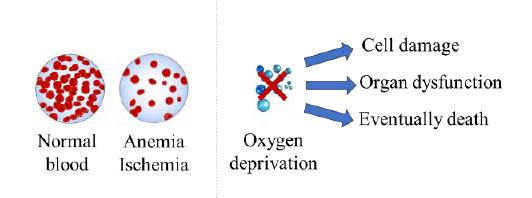

We are a biotechnology company focused on the development, manufacture, and commercialization of a proprietary technology platform for oxygen-carrying solutions that address critical unmet medical needs in both human and veterinary medicine. Using our patents, proprietary technology and know-how, we develop and sell products that, under certain conditions, are a possible alternative to blood transfusions to deliver oxygen to organs and tissues. Through numerous clinical studies, our products have been shown to address many of the current limitations that exist for blood transfusion. These include the limited shelf life of blood, logistical challenges of typing/cross-matching, delays in testing for pathogens, and blood shortages during times of high need and/or insufficient donations. We have significant experience gained through extensive pre-clinical and clinical testing of these products, which have a well-understood and extensively documented safety and efficacy profile.

| 5 |

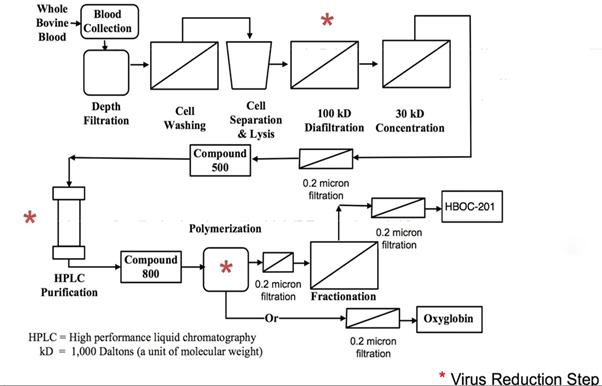

Management believes that our products are the only hemoglobin-based oxygen carriers (HBOCs) which have received marketing authorizations anywhere in the world. These products were acquired from OPK Biotech LLC in 2014, which had previously purchased them from Biopure Corporation in 2009. Our current products are:

| ● | Hemopure ® (hemoglobin glutamer -250 (bovine); HBOC-201) – for human use; and | |

| ● | Oxyglobin® (hemoglobin glutamer -200 (bovine) HBOC-301) - for veterinary use. |

Hemopure and Oxyglobin are sterile medicinal products administered via intravenous or arterial infusion that deliver oxygen to organs and tissues that could provide a potential alternative to blood transfusion. Our sterile veterinary and human products have been widely investigated in pre-clinical models, clinical trials and real-world clinical experience for more than 20 years and described in at least 250 peer-reviewed publications in the scientific literature and reference texts.

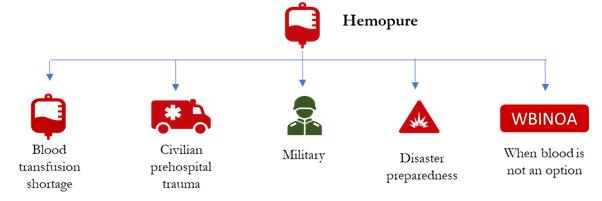

Hemopure, our human product, can address some of the logistical limitations of blood transfusions. The potential benefits are a reduction in both mortality and morbidity while offering several strategic advantages, such as universal compatibility, room temperature storage, off-the-shelf availability, readiness for use (supplied in sterile IV infusion bags) and a three-year shelf life. Clinical data suggests that Hemopure could provide a life-saving option for patients. In markets where Hemopure is not yet authorized or approved, approval(s) for Hemopure would be pursued for an indication when suitable blood transfusion is indicated, but not readily available, or an option.

Oxyglobin is the only oxygen-carrying solution approved by the US Food and Drug Administration (FDA), the European Medicines Agency (“EMA”) and the British Veterinary Medicines Directorate (“VMD”) to treat all-cause canine anemia.

We are also pursuing a medical device indication for Hemopure under the name ZK1. ZK1 is intended to act as an additive oxygen carrier solution during ex-vivo, sub-sub normothermic and normothermic machine perfusion of organs to recondition and assess organ viability prior to transplantation.

Product Portfolio Characteristics

The key characteristics of our product portfolio are:

| ● | Sterile, ultra-purified, oxygen-carrying solutions for intravenous or intra-arterial infusion, for the purpose of increasing total Hb concentration | |

| ● | No type and crossmatch required, and compatible with all blood types | |

| ● | Ready to use, requiring no reconstitution | |

| ● | Stable for at least three years at 2° to 30° Celsius | |

| ● | No refrigeration required | |

| ● | Carry oxygen at low perfusion pressure through constricted or partially blocked blood vessels to areas of the body that allogenic red blood cells (RBCs) cannot reach due to their larger size |

Markets

Our immediate focus is to relaunch Hemopure and Oxyglobin under approved indications in those jurisdictions where they already have marketing authorizations. The clinical development of ZK1 and Hemopure product candidates will continue in parallel, targeting markets for future approvals.

| 6 |

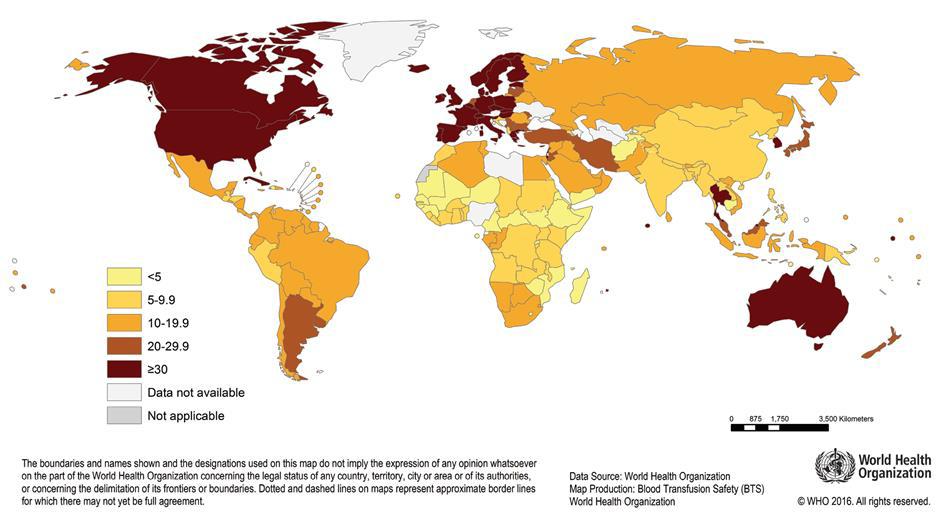

Human Transfusion Market

Hemopure is approved in South Africa to eliminate, delay, or reduce the need for RBC s in adult surgical patients. Hemopure was also approved in the Russian Federation for the treatment of acute, all-cause anemia. When the situation normalizes in that country and sanctions are lifted, we will evaluate reactivating the license and conclude a distribution agreement.

In the United States, Hemopure is under clinical development for the treatment of life-threatening anemia when blood transfusion is unavailable, or otherwise indicated but is not an option.

Human Organ Perfusion System Market

Clinical development of ZK1 for use in sub-normothermic and normothermic organ perfusion, without the use of traditional blood products is ongoing. Under this application ZK1 would not be administered to the patient, but instead used outside the body, as an additive to perfusion solutions for the ex-vivo machine perfusion of donor organs prior to transplantation. As an ancillary medicinal product used outside the body as one component of a machine perfusion system, ZK1 would be evaluated under a medical device application.

Multiple scientific journal articles describing the use of ZK1 as an adjunct to ex-vivo machine perfusion of donor organs prior to transplantation have generated considerable interest amongst the organ transplantation community resulting in preclinical and clinical research, to evaluate donor organ resuscitation and viability at several academic hospitals in the US and Europe.

Veterinary Market

Oxyglobin is the trademark name for our veterinary drug, the only oxygen carrying solution to be approved in the United States, the European Union and the United Kingdom to treat all cause anemia in dogs. Oxyglobin has additionally been used by veterinarians in Canada through Health Canada’s Emergency Drug Release (EDR) program. We plan to distribute Oxyglobin in North America through an exclusive distribution agreement with Dechra Veterinary Products, a global veterinary pharmaceutical company, and in Europe through regional distributors specializing in the veterinary critical care market.

Under the US Department of Defense Joint Theater Trauma System (“JTTS”) Clinical Practice Guideline for emergency treatment of military working dogs (“MWD”) that sustained combat related injuries, Oxyglobin was used as a resuscitative fluid to stabilize military working dogs (“MWD”) after combat-related injuries, in preparation for removal by MEDEVAC transport to veterinarians. The guideline was first published in April 2011 for non-veterinarians (i.e., human trauma surgeons and medics).

Veterinarians have limited treatment options when it comes to treating anemia in other species, as finding a healthy same species blood donor is not always practical. Oxyglobin’s long shelf life, and the ability to provide oxygen carrying capacity while stabilizing a patient in order to treat the underlying condition, led to practitioners using the product off-label in a variety of different species. The off-label use of Oxyglobin has been extensively published in peer reviewed literature, and veterinary reference texts. Examples of other species in which Oxyglobin has been used are feline, equine, avian, and exotics. Though still less common, avian and exotic pets are becoming increasingly popular companion animal choices, and therefore require veterinary care. Once Oxyglobin is relaunched in the canine market, we will seek to expand its use, to treat non-domestic animals in captivity, such as those zoos, aquariums or wild animal sanctuaries. This would involve filing a request for MUMS (Minor Use and Minor Species) drug designation. This permits the use of a drug in minor species, or for use in major species afflicted with uncommon diseases or conditions (minor uses).

| 7 |

Risks Associated with Our Business

Our business is subject to a number of risks of which you should be aware of before making an investment decision. These risks are discussed more fully in the “Risk Factors” section of this prospectus immediately following this prospectus summary. Primarily, our manufacturing facility is under construction to accommodate the additional process steps resulting from consolidation of the two other facilities. In order to do so, we must refit our newly constructed facility in Souderton, Pennsylvania with the equipment necessary for manufacturing and packaging, which has been relocated from facilities in Cambridge, Massachusetts and Ontario, Canada. Our ability to initially start manufacturing our products and generating revenues is substantially dependent upon the successful completion of the construction and re-fitting of our Souderton facility. Until it is complete, and the relevant cGMP certification is received, we will not be able release and commercially distribute any product. The proceeds of the Offering will be insufficient to fully complete the relaunch of our products into the market. We will require approximately $15 million of additional monies to complete this process. If we do not successfully raise such monies through public or private equity or debt financings or other sources, such as strategic collaborations or license and development agreements, the facility cannot be completed and we will be unable to produce and commercially distribute any product.

In addition to the risks associated with our facility, some of the risks involved with the offering include the following:

| ● | We have incurred substantial losses since our inception and anticipate that we will continue to incur substantial and increasing losses for the foreseeable future. | |

| ● | We will require substantial additional financing to achieve our goals, and a failure to obtain this necessary capital when needed could force us to delay, limit, reduce or terminate our product development or commercialization efforts. | |

| ● | We currently have very limited revenues. We may never generate significant revenues or achieve profitability. | |

| ● | We expect to continue to incur significant operating and non-operating expenses, which may make it difficult for us to secure sufficient financing. Our recurring losses from operations raise substantial doubt about our ability to continue as a going concern. As a result, our independent registered public accounting firm included an explanatory paragraph in its report on our financial statements for the year ended December 31, 2021 with respect to this uncertainty. | |

| ● | It is possible that we may face substantial competition caused by others discovering, developing or commercializing products before or more successfully than we do. | |

| ● | If we are unable to successfully develop and commercialize our product candidates or experience significant delays in doing so, our business may be materially harmed. | |

| ● | Our success relies on third-party suppliers and manufacturers. Any failure by such third parties, including, but not limited to, failure to successfully perform and comply with regulatory requirements, could negatively impact our business and our ability to develop and market our product candidate, and our business could be substantially harmed. | |

| ● | Our future success is dependent on the regulatory approval of our product candidates. | |

| ● | Our business may be adversely affected by the ongoing coronavirus pandemic. | |

| ● | Business interruptions could adversely affect future operations, revenues, and financial condition, and may increase our cost of doing business. | |

| ● | We may infringe the intellectual property rights of others, which may prevent or delay our product development efforts. | |

| ● | Our intellectual property may not be sufficient to protect our products from competition. |

| 8 |

Implications of Being an Emerging Growth Company and a Smaller Reporting Company

We are an “emerging growth company” as defined in the Jumpstart Our Business Startups Act, or the JOBS Act, enacted in April 2012, and we will remain an emerging growth company until the earliest to occur of: the last day of the fiscal year in which we have more than $1.07 billion in annual revenue; the date we qualify as a “large accelerated filer,” with at least $700 million of equity securities held by non-affiliates; the issuance, in any three-year period, by us of more than $1.0 billion in non-convertible debt securities; and the last day of the fiscal year ending after the fifth anniversary of our initial public offering. For so long as we remain an emerging growth company, we are permitted and intend to rely on certain exemptions from various public company reporting requirements, including not being required to have our internal control over financial reporting audited by our independent registered public accounting firm pursuant to Section 404(b) of the Sarbanes-Oxley Act of 2002, reduced disclosure obligations regarding executive compensation in our periodic reports and proxy statements, and exemptions from the requirements of holding a nonbinding advisory vote on executive compensation and any golden parachute payments not previously approved. In particular, in this prospectus, we have provided only two years of audited financial statements and have not included all of the executive compensation-related information that would be required if we were not an emerging growth company. Accordingly, the information contained herein may be different than the information you receive from other public companies in which you hold stock.

In addition, the JOBS Act provides that an emerging growth company can take advantage of an extended transition period for complying with new or revised accounting standards. This provision allows an emerging growth company to delay the adoption of some accounting standards until those standards would otherwise apply to private companies. We have elected to take advantage of the extended transition period to comply with new or revised accounting standards and to adopt certain of the reduced disclosure requirements available to emerging growth companies. As a result, we will not be subject to the same implementation timing for new or revised accounting standards as other public companies that are not emerging growth companies which may make comparison of our financial statements to those of other public companies more difficult. As a result of this election, the information that we provide in this prospectus may be different than the information you may receive from other public companies in which you hold equity interests.

We are also a smaller reporting company as defined in the Securities Exchange Act of 1934, as amended. We may continue to be a smaller reporting company even after we are no longer an emerging growth company. We may take advantage of certain of the scaled disclosures available to smaller reporting companies and will be able to take advantage of these scaled disclosures for so long as (i) the market value of our voting and non-voting common stock held by non-affiliates is less than $250 million measured on the last business day of our second fiscal quarter or (ii) our annual revenue is less than $100 million during the most recently completed fiscal year and the market value of our voting and non-voting common stock held by non-affiliates is less than $700 million measured on the last business day of our second fiscal quarter. Specifically, as a smaller reporting company, we may choose to present only the two most recent fiscal years of audited financial statements in our Annual Report on Form 10-K and have reduced disclosure obligations regarding executive compensation, and, similar to emerging growth companies, if we are a smaller reporting company with less than $100 million in annual revenue, we would not be required to obtain an attestation report on internal control over financial reporting issued by our independent registered public accounting firm.

Corporate Information

We were formed as a Delaware limited liability company in February 2014. Prior to the closing of this offering, Hemoglobin Oxygen Therapeutics LLC intends to convert into a Delaware corporation pursuant to a statutory conversion, and will change its name to Hemoglobin Oxygen Therapeutics Inc. See “Corporate Conversion.”

| 9 |

Hemoglobin Oxygen Therapeutics LLC was organized in February 2014 in connection with the acquisition of OPK Biotech LLC through a Chapter 7 bankruptcy auction. The assets we acquired from OPK Biotech LLC consisted of equipment, intellectual property, finished product inventory and the capital stock of companies incorporated in the Netherlands and South Africa. OPK Biotech had in turn acquired certain assets from Biopure Corporation and intellectual property from Northfield Laboratories. Our principal executive offices are located at 674 Souder Road, Souderton, PA 18964 and our telephone number is (267) 382-0064. Our website address is www.hbo2therapeutics.com. The information contained on our website is not incorporated by reference into this prospectus, and you should not consider any information contained on, or that can be accessed through, our website as part of this prospectus or in deciding whether to invest in our common stock.

Product History

Biopure Corporation developed a veterinary (Oxyglobin) and a human (Hemopure) product and by the end of 1990’s received its veterinary product approval by the FDA (US) and the EMA (EU). The expensive production process, however, did not allow Biopure to sell the veterinary product at a profit and the Company continued its pursuit of human approval. Biopure went public in the early 2000s and traded at a market capitalization in excess of a billion dollars. The total funds spent by Biopure on the product development during its existence was around $900 million.

In the early-2000s, an ill-designed Phase 3 clinical trial protocol followed by several managerial missteps led to difficulties, and Biopure was sold in 2009 to OPK Biotech (beneficial owner Sergey Pugachev). The new owner invested an additional $100 million to improve the production process resulting in significant reductions in the cost of producing the company’s products. In 2011, Mr. Pugachev became involved in litigation with the Russian government which resulted in the expropriation of all his Russian assets. The beneficial owner’s financial difficulties in Russia and inability to financially support the company led to conflict with the management of OPK Biotech, resulting in OPK Biotech management departure from the Company in early 2013. In 2014, creditors of OPK Biotech initiated a Chapter 7 bankruptcy process, which eventually resulted in the seizure of OPK assets and the sale of such assets through an auction.

Hemoglobin Oxygen Therapeutics LLC was formed in 2014 with the sole purpose of buying the assets of OPK Biotech. HbO2 Therapeutics participated in that auction and won the bid. After purchasing those assets in late 2014, HbO2 Therapeutics elected to consolidate three production facilities and house the whole process under one roof in Souderton, PA. Currently all of the equipment is waiting to be assembled in the newly erected building in Souderton, pending the proceeds of this Offering.

| 10 |

THE OFFERING

| Shares offered by us | ___ shares. | |

| Common stock outstanding prior to this offering | ___ shares | |

| Common stock to be outstanding immediately after this offering | _______ shares ( _______shares if the underwriters exercise their over-allotment option in full) | |

| Option to purchase additional shares | The underwriters have an option for a period of 45 days to purchase up to an additional ____shares of our common stock and/or Warrants to purchase up to ___ additional shares of our common stock (equal to 15% of the number of shares of common stock sold in the offering), from us in any combination thereof. | |

| Use of proceeds | We estimate that the net proceeds from this offering will be approximately $___, or approximately $____if the underwriters exercise their over-allotment option in full, at an assumed public offering price of $___ per share, after deducting the underwriting discounts and commissions, the non-accountable expense allowance payable to the underwriters, and estimated offering expenses payable by us. We intend to use approximately $20 million of the net proceeds from this offering toward reassembling our facility in Souderton, Pennsylvania and the balance for general corporate expenses and working capital. See “Use of Proceeds” for a more complete description of the intended use of proceeds from this offering. | |

| Lock-up agreements | Our executive officers, directors and shareholders have agreed with the underwriters not to sell, transfer or dispose of any shares or similar securities for a period of 180 days after the date of this prospectus. For additional information regarding our arrangement with the underwriters, please see “Underwriting.” | |

| Risk factors | See “Risk Factors” on page 14 and other information included in this prospectus for a discussion of factors to consider carefully before deciding to invest in shares of our common stock. | |

| Proposed Nasdaq Capital Market symbol | HOTI |

The number of shares of common stock outstanding is based on _____shares of our common stock outstanding as of December 31, 2021 after giving effect to (i) the Corporate Conversion to occur immediately prior to the effective date of this offering and (ii) the issuance of _____ shares of common stock issuable upon conversion of convertible and other indebtedness immediately prior to the effective date of this offering assuming an initial public offering price of $____per share, which is the midpoint of the price range set forth on the cover page of this prospectus (the “Debt Conversion”) and excludes as of such date:

| ● | 922,011 and [ ] shares of common stock issuable upon exercise of the outstanding common stock warrant at an exercise price of $2.75 and $[ ] per common share, respectively. | |

| ● | [ ] shares of common stock reserved for future grants pursuant to our 2022 Equity Incentive Plan. | |

| ● | [ ] shares of common stock issuable upon exercise of warrants to be issued to the underwriters as part of this offering at an exercise price of $[ ] per common share (120% of the assumed public offering price of $[ ] per share). |

Except as otherwise indicated herein, all information in this prospectus assumes or gives effect to:

| ● | [ ] shares of common stock issuable upon conversion of our outstanding convertible notes in an aggregate principal amount of $6,930,000. | |

| ● | [ ] shares of common stock issuable upon conversion of debt held by our facilities’ landlord in an aggregate principal amount of $2,000,000 | |

| ● | [ ] shares of common stock issuable upon conversion of debt held by the engineering firm building our facilities, in an aggregate principal amount of $486,000. | |

| ● | The retroactive effect of the conversion of our former limited liability company to a C corporation, to be effected on consummation of the offering. | |

| ● | No exercise by the underwriters of their option to purchase an additional [ ] shares of common stock. |

| 11 |

Financial Statement Presentation

The financial statements for the years ended December 31, 2021 and 2020, represent the operations of Hemoglobin Oxygen Therapeutics LLC. In connection with the closing of this offering, Hemoglobin Oxygen Therapeutics LLC will complete a Corporate Conversion into a Delaware corporation pursuant to a statutory conversion, and will change its name to Hemoglobin Oxygen Therapeutics Inc. All holders of membership interests of Hemoglobin Oxygen Therapeutics LLC will become holders of shares of common stock of Hemoglobin Oxygen Therapeutics Inc., as described under the heading “Corporate Conversion.” In this prospectus, we refer to all transactions related to our conversion to a corporation as the Corporate Conversion. We expect that the Corporate Conversion will not have a material effect on our financial statements.

| 12 |

Selected Summary Consolidated Financial Data

The following tables set forth selected consolidated summary financial data as of the dates and for the periods indicated. We have derived the summary statement of operations data for the years ended December 31, 2021 and 2020 from our audited financial statements included elsewhere in this prospectus. The summary statements of operations data for the years ended December 31, 2021 and 2020 and the summary balance sheet data as of December 31, 2021 have been derived from our audited financial statements included elsewhere in this prospectus. The following summary financial data should be read in conjunction with “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and our financial statements and related notes and other information included elsewhere in this prospectus. Our historical results are not necessarily indicative of the results to be expected in the future.

| Consolidated Statement of Operations Data: | ||||||||

Years Ended December 31, | ||||||||

| 2021 | 2020 | |||||||

| Revenues | $ | - | $ | 35,470 | ||||

| Operating expenses | ||||||||

| Research and development | 768,621 | 571,738 | ||||||

| General and administrative | 2,668,311 | 2,673,445 | ||||||

| Total operating expenses | 3,436,932 | 3,245,183 | ||||||

| Loss from operations | (3,436,932 | ) | (3,209,713 | ) | ||||

| Other Income and expense | ||||||||

| Interest expense | (681,518 | ) | (379,862 | ) | ||||

| Gain on paycheck protection program loan forgiveness | 206,200 | - | ||||||

| Loss on extinguishment of debt | (2,235,770 | ) | - | |||||

| Gain on foreign currency translation | - | 1,699 | ||||||

| Gain on change in fair value of warrant liability | 21,782 | 1,862 | ||||||

| Total other expense | (2,689,306 | ) | (376,301 | ) | ||||

| Net loss | $ | (6,126,238 | ) | $ | (3,586,014 | ) | ||

| Loss per unit – basic and diluted | $ | (33.16 | ) | $ | (19.65 | ) | ||

| Weighted average units outstanding – basic and diluted | 184,763 | 182,451 | ||||||

| Balance Sheet Data | ||||||||||||

As of December 31, 2021 (Pro Forma and Pro Forma As Adjusted is unaudited) | ||||||||||||

| Actual | Pro Forma 1 | Pro Forma As Adjusted 2, | ||||||||||

| Cash | $ | 443,895 | $ | 443,895 | $ | - | ||||||

| Total assets | $ | 6,034,988 | $ | 6,034,988 | $ | - | ||||||

| Total liabilities | $ | 15,284,136 | $ | 7,159,411 | $ | - | ||||||

| Total members’ deficit | $ | (9,249,148 | ) | $ | - | $ | - | |||||

| Total stockholders’ deficit | $ | - | $ | (1,124,423 | ) | $ | - | |||||

1 As presented in the unaudited pro forma financial information included within this prospectus, pro forma gives effect to (1) the Corporate Conversion; (2) the conversion of the following principal amount of convertible indebtedness, plus interest accrued and unpaid interest where indicated below, immediately prior to the effective date of this offering assuming an IPO Price of $____per share, which is the midpoint of the price range set forth on the cover page of this prospectus, (i) $6,930,000 with maturity dates ranging from July 2022 to September 2025, bearing interest at rates ranging from 5% to 10% per annum convertible into an estimated _____shares of common stock at varying conversion prices from $2.75 to $5.49 and (ii) $2,000,000 due on demand bearing [no] interest convertible into an estimated _____shares of common stock (a 25% discount to the IPO Price). (iii) $486,000 due on demand bearing [no]interest convertible into an estimated _____shares of common stock (a 25% discount to the IPO Price)

2 As will be presented in the section labeled “Capitalization” included within this Prospectus, pro forma as adjusted amounts reflect the sale of shares of our common stock in this offering at the assumed public offering of $ per share, which is the midpoint of the price range set forth on the cover page of this prospectus, and after deducting the estimated underwriting discounts and commissions and estimated offering expenses payable by us. Each $1.00 increase (decrease) in the assumed public offering price of $ per share , which is the midpoint of the price range set forth on the cover page of this prospectus, would increase (decrease) each of cash, additional paid-in capital, total stockholders’ (deficit) equity and total capitalization by approximately $ million, assuming that the number of shares by us, as set forth on the cover page of this Prospectus, remains the same, and after deducting the estimated underwriting discounts and commissions and estimated offering expenses payable by us. Similarly, each increase (decrease) of 1 million shares the number of shares offered by us would increase (decrease) the pro forma as adjusted amount of each of cash, additional paid-in capital, total stockholders’ (deficit) equity and total capitalization by approximately $ million, assuming that the assumed public offering price remains the same, and after deducting the estimated underwriting discounts and commissions and the estimated offering expenses payable by us. Additionally pro forma as adjusted includes $20 million of proceeds from the offering in total assets and total stockholders’ equity (deficit) related to the reassembly of the company’s facility in Souderton utilizing proceeds of this offering.

| 13 |

An investment in our common stock involves a high degree of risk. Before making an investment decision, you should give careful consideration to the following risk factors, in addition to the other information included in this prospectus, including our financial statements and related notes, before deciding whether to invest in shares of our common stock. The occurrence of any of the adverse developments described in the following risk factors could materially and adversely harm our business, financial condition, results of operations or prospects. In that case, the trading price of our common stock could decline, and you may lose all or part of your investment.

Risks Relating to Our Financial Position and Capital Needs

We have incurred significant losses since our inception and anticipate that we will continue to incur losses for the foreseeable future. We have generated very limited revenues since our inception, which may make it difficult for you to assess our future viability.

We are not profitable and have incurred losses in each year since our founding in February 2014, following the acquisition of our assets from OPK Biotech LLC, which in turn acquired them from Biopure Corporation. Our net losses for the years ended December 31, 2021 and 2020 were $6.3 million and $3.6 million, respectively. As of December 31, 2021, we had a members’ deficit of $9.4 million. We have financed our operations primarily through the sale of equity securities and convertible debt. We continue to incur significant expenses related to our ongoing operations and expect to incur losses for the foreseeable future. We anticipate these losses will increase as we:

| ● | build and refit our Souderton facility; | |

| ● | obtain the requisite regulatory approvals for the new facility, which will enable the relaunch of Oxyglobin, and reintroduction of Hemopure in the applicable approved markets; | |

| ● | continue to advance the development and pursue approvals for ZK-1, as well as commercialization of Oxyglobin, Hemopure and ZK1; | |

| ● | expand the Oxyglobin markets and obtain additional regulatory and marketing approvals into new indications and new countries; | |

| ● | continue the development of Oxyglobin and Hemopure for unapproved indications and markets; and | |

| ● | expand our organization to support our research, development and commercialization activities and our operations as a public company. |

We have generated very limited revenues from product sales since we became the successor of Biopure and OPK Biotech, because our manufacturing facility is not currently operational. We may never be able to complete the construction or retrofit of our manufacturing facility or relaunch or commercialize our products or any product candidates to any significant degree or achieve profitability. Even if we achieve profitability in the future, we may not be able to sustain profitability in subsequent periods. Our failure to achieve sustained profitability would depress the value of our Company and could impair our ability to raise capital, expand our business, diversify our research and development pipeline, market our products or product candidates we may identify and pursue, if approved, or continue our operations. Our prior losses, combined with expected future losses, have had and will continue to have an adverse effect on our stockholders’ equity and working capital.

Our management has concluded that factors raise substantial doubt about our ability to continue as a going concern and our independent registered public accounting firm has included an explanatory paragraph relating to our ability to continue as a going concern in its report on our audited financial statements included in this Registration Document.

Our recurring losses from operations raise substantial doubt about our ability to continue as a going concern. As a result, our independent registered public accounting firm included an explanatory paragraph in its report on our financial statements for the year ended December 31, 2021 with respect to this uncertainty. Our ability to continue as a going concern will require us to obtain additional funding. We believe that the net proceeds from this Offering, together with our existing cash, will enable us to fund our operating expenses and debt service payments through April 2023. However, we will need approximately $15 million in additional funds to complete the reassembly, validation and certification of the Souderton, Pennsylvania facility. We have based these estimates on assumptions that may prove to be wrong, and we could exhaust our available capital resources sooner than we expect. If we are unable to raise capital when needed or on acceptable terms, we would be forced to delay, or discontinue the further development and commercialization efforts of one or more of our products and/or product candidates or may be forced to reduce or terminate our operations.

| 14 |

Our ability to start manufacturing our products and generating revenues is dependent upon the successful completion of the construction and re-fitting of our Souderton facility. While we plan on using a significant portion of the proceeds of this offering towards the construction and re-fitting of the facility, the proceeds of this offering will not be sufficient to complete this process. We will require approximately $15 million of additional monies to complete this process. If we do not successfully raise such monies, the facility cannot be completed, and we will be unable to produce and commercially distribute any product.

In order to start manufacturing our products and generating revenues, we must successfully complete the construction and re-fitting of our Souderton facility with the equipment necessary for manufacturing and packaging, which has been relocated from facilities in Cambridge, Massachusetts and Ontario, Canada and obtain the relevant cGMP certification. While we plan on using a significant portion of the proceeds of this offering towards the construction and re-fitting of the facility, the proceeds of this offering will not be sufficient to complete this process. We will require approximately $15 million of additional monies to complete this process. We will need to seek such additional funds through public or private equity or debt financings or other sources, such as strategic collaborations or license and development agreements. If we do not successfully raise such monies, the facility cannot be completed, and we will be unable to produce and commercially distribute any product.

Such construction and re-fitting may also be subject to unforeseen delays and cost overruns which would negatively impact our business and results of operations. The construction and refit are also subject to our ability to hire sub-contractors with sufficient availability and obtain and comply with regulatory or other licenses and permits. If the construction of the Souderton facility is delayed or is not completed, we will not be able to manufacture our products and generate any material revenues, which would adversely affect our ability to operate and continue our business.

Once we begin conducting all of our manufacturing operations at the single facility in Souderton, Pennsylvania, any interruption in operations at such facility could result in our inability to satisfy demand for our approved products. Despite our efforts to safeguard this facility, including acquiring insurance on commercially reasonable terms, adopting environmental health and safety protocols and utilizing off-site storage of computer data, a number of factors could damage or destroy our manufacturing equipment or our inventory of component supplies or finished goods, cause substantial delays in our operations, result in the loss of key information, and cause us to incur additional expenses, including:

● relocation expense;

● operating restrictions, partial suspension or total shutdown of production imposed by regulatory authorities;

● equipment malfunctions or failures;

● technology malfunctions;

● work stoppages;

● damage to or destruction of the facility due to natural disasters or other events; and

● regional or local power shortages.

| 15 |

We will require additional funding to achieve our business goals. If we are unable to obtain this funding when needed and on acceptable terms, we would be forced to delay, limit or terminate our product development efforts or other operations. Raising additional capital may subject us to unfavorable terms, cause dilution to our existing stockholders, restrict our operations or require us to relinquish rights to our approved products, product candidates, and technologies.

As mentioned above, we plan on using a significant portion of the proceeds of this offering towards the construction and re-fitting of our Souderton facility. The proceeds of this offering will not be sufficient to complete this process and we require approximately $15 million of additional monies to complete this process.

In addition, we are currently developing new indications for Oxyglobin and Hemopure, and ZK1. Developing and commercializing biopharmaceutical products and medical devices is expensive and time-consuming, and we expect our research, development and manufacturing expenses to increase substantially in connection with our ongoing activities. As of December 31, 2021, we had negative working capital of $13.5 million and capital resources consisting of cash of approximately $0.4 million. Because the outcome of any clinical development and regulatory approval process is highly uncertain, we cannot reasonably estimate the actual capital amounts necessary to successfully complete the development, regulatory approval process and commercialization of ZK1 and new indications of Oxyglobin and Hemopure.

Any additional fundraising efforts may divert our management from their day-to-day activities, which may adversely affect our ability to commercialize our approved products and develop and commercialize ZK1 or new indications of Oxyglobin and Hemopure and any other product candidates that we may identify and pursue. Moreover, such financing may result in dilution to stockholders, imposition of debt covenants and repayment obligations, or other restrictions that may affect our business. In addition, we may seek additional capital due to favorable market conditions or strategic considerations even if we believe we have sufficient funds for our current or future operating plans. Additional funds may not be available when we need them, on terms that are acceptable to us, or at all. If adequate funds are not available to us on a timely basis, we may be required to delay, limit or terminate the commercialization or our approved products or the development of one or more of our programs for new indications of Oxyglobin and Hemopure and our product candidates or be unable to expand our operations or otherwise capitalize on our business opportunities, as desired, which could materially and adversely affect our business, prospects, financial condition and results of operations.

Risks Related to the Development and Regulatory Approval of our Product Candidates or New Indications of our Approved Products

Any biopharmaceutical products or medical devices advanced into clinical development are subject to extensive regulation, which can be costly and time consuming, cause unanticipated delays or prevent the receipt of the required approvals to commercialize such product or device.

The clinical development, manufacturing, labeling, storage, record-keeping, advertising, promotion, import, export, marketing and distribution of biopharmaceutical products are subject to extensive regulation by the FDA in the U.S. and by comparable health authorities in foreign markets. In the U.S., the FDA must approve the new facility and products manufactured there, as complying with Good Manufacturing Practice (‘cGMP’). The process of obtaining approval is expensive, often takes many years and can vary substantially based upon the type, complexity and novelty of the proposed new indications, with respect to Oxyglobin and Hemopure, or the product candidate involved. In addition to the significant clinical testing requirements, our ability to obtain marketing approval for these proposed new indications, with respect to Oxyglobin and Hemopure, or the product candidates depends on obtaining the final results of required non-clinical testing, including characterization of the manufactured components of such products and validation of our manufacturing processes. The FDA may determine that our manufacturing processes, testing procedures or facilities are insufficient to justify approval. Approval policies or regulations may change, and the FDA has substantial discretion in the approval process, including the ability to delay, limit or deny approval of a product candidate for many reasons. Despite the time and expense invested in clinical development of product candidates, regulatory approval is never guaranteed.

| 16 |

The FDA or another regulatory agency can delay, limit or deny approval of a proposed new indication, with respect to Oxyglobin or Hemopure, or a product candidate for many reasons, including, but not limited to:

| ● | the FDA or comparable foreign regulatory authorities may disagree with the design or implementation of clinical trials; | |

| ● | we may be unable to demonstrate to the satisfaction of the FDA that a proposed new indication, with respect to Oxyglobin and Hemopure, or a product candidate is safe and effective for any indication; | |

| ● | the FDA may not accept clinical data from trials which are conducted by individual investigators or in countries where the standard of care is potentially different from the U.S.; | |

| ● | the results of clinical trials may not meet the level of statistical significance required by the FDA for approval; | |

| ● | we may be unable to demonstrate that a proposed new indication, with respect to Oxyglobin and Hemopure, or a product candidate’s clinical and other benefits outweigh its safety risks; | |

| ● | the FDA may disagree with our interpretation of data from preclinical studies or clinical trials; | |

| ● | the FDA may fail to approve the manufacturing processes or facilities of third-party manufacturers with which we or our collaborators contract for clinical and commercial supplies; or | |

| ● | the approval policies or regulations of the FDA may significantly change in a manner rendering our clinical data insufficient for approval. |

With respect to foreign markets, approval procedures vary among countries and, in addition to the aforementioned risks, can involve additional product testing, administrative review periods and agreements with pricing authorities. Any delay in obtaining, or inability to obtain, applicable regulatory approvals with respect to new indications and new markets could prevent us from commercializing any proposed new indications, with respect to Oxyglobin and Hemopure, or our product candidates.

Any proposed new indication with respect to Oxyglobin and Hemopure, or other product candidates that we advance into clinical trials, may cause unacceptable adverse events or have other properties that may delay or prevent their regulatory approval or commercialization or limit their commercial potential.

Unacceptable adverse events caused by any proposed new indication, with respect to Oxyglobin and Hemopure, or other product candidates that we advance into clinical trials, could cause us or regulatory authorities to interrupt, delay or halt clinical trials and could result in the denial of regulatory approval by the FDA or other regulatory authorities for any or all targeted indications and markets. This, in turn, could prevent us from commercializing the affected proposed new indication, with respect to Oxyglobin and Hemopure, or product candidate in such indication or market and generating revenues from its sale. Hemopure remains under clinical development, and we cannot know the extent of any unexpected adverse events in future clinical trial patients. Any unforeseen safety issues with a product candidate could prevent and/or delay the regulatory approval process.

Delays in the commencement of clinical trials could result in increased costs and delay our ability to pursue regulatory approval.

The commencement of clinical trials can be delayed for a variety of reasons, including delays in:

| ● | obtaining regulatory clearance to commence a clinical trial; | |

| ● | identifying, recruiting and training suitable clinical investigators; |

| 17 |

| ● | reaching mutually agreeable contract terms for research agreements with large institutional sites; | |

| ● | maintaining adequate levels of clinical trial supplies (including investigational drug products); | |

| ● | obtaining an IRB or ethics committee approval to conduct a clinical trial at a prospective site; | |

| ● | identifying, recruiting and enrolling patients to participate in a clinical trial; and | |

| ● | early withdrawal of clinical trial participants for any reason, related to product safety issues or otherwise. |

Any delays in the commencement of clinical trials will delay our ability to pursue regulatory approval for any proposed new indications. In addition, many of the factors that cause, or lead to, a delay in the commencement of clinical trials may also ultimately lead to the denial of regulatory approval of a proposed new indication with respect to Oxyglobin and Hemopure, or a product candidate.

Suspensions or delays in the completion of clinical testing could result in increased costs to us and delay or prevent our ability to complete development of that product or generate product revenues.

Once a clinical trial has begun, patient recruitment and enrollment may be slower than we anticipate. Clinical trials may also be delayed as a result of ambiguous or negative interim results or difficulties in obtaining sufficient quantities of product manufactured in accordance with regulatory requirements. Further, a clinical trial may be modified, suspended or terminated by us, an Institutional Review Board (IRB), a hospital ethics committee, data safety monitoring oversight committee, or any regulatory authority due to a number of factors, including:

| ● | protocol non-compliance | |

| ● | violations of Good Clinical Practice (GCP) by us, investigator sites, or vendors contracted on our behalf | |

| ● | stopping rules contained in the protocol; | |

| ● | unforeseen safety issues or any determination that the clinical trial presents unacceptable health risks; and | |

| ● | lack of adequate funding to continue the clinical trial. |

Any changes in the current regulatory requirements and guidance also may occur, and we may need to amend clinical trial protocols to reflect these changes. Amendments may require us to resubmit clinical trial protocols to IRBs and regulatory authorities for additional review, which may impact the costs, timing and the likelihood of a successful completion of a clinical trial. If we experience delays in the completion of, or if we must suspend or terminate, any clinical trial with respect to a proposed new indication or any product candidate, our ability to obtain regulatory approval will be delayed, and the commercial prospects, if any, for the proposed new indication, or approval may suffer as a result. In addition, many of these factors may also ultimately lead to the denial of regulatory approval.

We may expend our limited resources to pursue a proposed new indication or approval for a product or product candidate and fail to capitalize on product candidates or indications for which there may be a greater likelihood of success.

Because we have limited financial and managerial resources, we may forego or delay pursuit of opportunities with new indications, with respect to Oxyglobin and Hemopure, or other product candidates for which there may be a greater likelihood of success or may prove to have greater commercial potential. Research programs to identify new product candidates or pursue alternative indications for approved products require substantial technical, financial and administrative support. We may never successfully develop any proposed new indication, with respect to Oxyglobin and Hemopure, or any product candidates.

| 18 |

We may incur substantial product liability or indemnification claims relating to the clinical testing of Oxyglobin and Hemopure for any proposed new indication or our product candidates.

We face an inherent risk of product liability exposure related to the testing of Oxyglobin and Hemopure for any proposed new indication or our product candidates in human clinical trials, and claims could be brought against us if use or misuse of Oxyglobin and Hemopure for any proposed new indication or one of our product candidates causes, or merely appears to have caused, personal injury or death. While we have and intend to maintain product liability insurance relating to our clinical trials, our coverage may not be sufficient to cover claims that may be made, and we may be unable to maintain such insurance. Any claims, regardless of their merit, could severely harm our financial condition, strain our management and other resources or destroy the prospects for commercialization of the product which is the subject of any such claim. We are unable to predict if we will be able to obtain or maintain product liability insurance for any products that may be approved for marketing. Additionally, it is expected that we will need to enter into various agreements where we indemnify third parties for certain claims relating to the testing of Oxyglobin and Hemopure for any proposed new indication or our product candidates. These indemnification obligations may require us to pay significant sums of money for claims that are covered by these indemnifications.

Our research and development activities could be affected or delayed as a result of possible restrictions on animal testing.

Certain laws and regulations require us to test our product candidates on animals before initiating clinical trials involving human patients. Animal testing activities have been the subject of controversy and adverse publicity. Animal rights groups and other organizations and individuals have attempted to stop animal testing activities by pressing for legislation and regulation in these areas and by disrupting these activities through protests and other means. To the extent the activities of these groups are successful, our research and development activities may be interrupted, delayed or become more expensive.

We may find it difficult to enroll patients in our clinical trials which could delay or prevent the start of clinical trials for our product candidates.

Identifying and qualifying patients to participate in clinical trials of Oxyglobin and Hemopure for any proposed new indication or our product candidates is essential to our success. The timing of our clinical trials depends in part on the rate at which we can recruit patients to participate in clinical trials of Oxyglobin and Hemopure for any proposed new indication or our product candidates, and we may experience delays in our clinical trials if we encounter difficulties in enrollment. If we experience delays in our clinical trials, the timeline for obtaining regulatory approval of Oxyglobin and Hemopure for any proposed new indication or our product candidates will most likely be delayed.

Many factors may affect our ability to identify, enroll and maintain qualified patients, including the following:

| ● | eligibility criteria of our ongoing and planned clinical trials with specific characteristics appropriate for inclusion in our clinical trials; | |

| ● | design of the clinical trial; | |

| ● | size and nature of the patient population; | |

| ● | patients’ perceptions as to risks and benefits of the proposed new indication of Oxyglobin and Hemopure or the product candidate under study and the participation in a clinical trial generally in relation to other available therapies; | |

| ● | the availability and efficacy of competing therapies and clinical trials; | |

| ● | pendency of other trials underway in the same patient population; | |

| ● | willingness of physicians to participate in our planned clinical trials; |

| 19 |

| ● | severity of the disease under investigation; | |

| ● | proximity of patients to clinical sites; | |

| ● | patients who do not complete the trials for personal reasons; and | |

| ● | issues with Contract Research Organizations (“CROs”) and/or with other vendors that handle our clinical trials. |

We may not be able to initiate or continue to support clinical trials for any proposed new indication or of our product candidates, for one or more applications, or any future proposed new indication, with respect to Oxyglobin and Hemopure, or product candidates if we are unable to locate and enroll a sufficient number of eligible participants in these trials as required by the FDA or other regulatory authorities. Even if we are able to enroll a sufficient number of patients in our clinical trials, if the pace of enrollment is slower than we expect, the development costs for Oxyglobin and Hemopure for any proposed new indication or our product candidates may increase and the completion of our trials may be delayed, or our trials could become too expensive to complete.

If we experience delays in the completion of, or termination of, any clinical trials of Oxyglobin and Hemopure for any proposed new indication or our product candidates, the commercial prospects of these could be harmed, and our ability to generate product revenue therefrom could be delayed or prevented. In addition, any delays in completing our clinical trials would likely increase our overall costs, impair development and jeopardize our ability to obtain regulatory approval relative to our current plans. Any of these occurrences may harm our business, financial condition, and prospects significantly.

Even if we successfully complete the construction and re-fitting of our Souderton facility, if the manufacturing facility does not meet regulatory requirements or, once operational, is unable to meet our supply demands, our business will be harmed.

We are involved in the preparation of therapeutics for clinical trials or commercial sale and are therefore subject to extensive regulation. These regulations govern manufacturing processes and procedures, including recordkeeping, and the implementation and operation of quality systems to control and assure the quality of investigational products and products approved for sale. Poor control of production processes can lead to the introduction of contaminants or to inadvertent changes in the properties or stability of our products. Our failure to comply with applicable regulations could result in sanctions being imposed on us, including fines, injunctions, civil penalties, delays, suspension or withdrawal of approvals, license revocation, suspension of production, seizures or recalls of products or marketed drugs, operating restrictions and criminal prosecutions, any of which could significantly and adversely affect clinical or commercial supplies of our products.

We must supply all necessary documentation in support of a Biologics License Application (“BLA”) or Marketing Authorisation Application (“MAA”) on a timely basis and must adhere to Good Laboratory Practices (“cGLP”) and Good Manufacturing Practices (“cGMP”) regulations enforced by the FDA and other regulatory agencies through their facilities inspection program. In addition, the regulatory authorities may, at any time, audit or inspect our manufacturing facility involved with the preparation of our products or our product or the associated quality systems for compliance with the regulations applicable to the activities being conducted. If our facility does not pass a pre-approval plant inspection, regulatory approval of the products may not be granted or may be substantially delayed until any violations are corrected to the satisfaction of the regulatory authority, if ever.

The regulatory authorities also may, at any time following approval of one of our products for sale, audit our manufacturing facility, if completed. If any such inspection or audit identifies a failure to comply with applicable regulations or if a violation of our product specifications or applicable regulations occurs independent of such an inspection or audit, we or the relevant regulatory authority may require remedial measures that may be costly and/or time consuming for us to implement, and that may include the temporary or permanent suspension of commercial sales or the temporary or permanent closure of our sole manufacturing facility. Any such remedial measures imposed upon us could materially harm our business.

| 20 |

Risks associated with operating in foreign countries could materially adversely affect our product development.

We may conduct future studies in countries outside of the United States. Consequently, we may be subject to risks related to operating in foreign countries. Risks associated with conducting operations in foreign countries include:

| ● | differing regulatory requirements for device approvals and regulation of approved devices in foreign countries; more stringent privacy requirements for data to be supplied to our operations in the U.S., e.g., General Data Protection Regulation in the European Union; | |

| ● | unexpected changes in tariffs, trade barriers and regulatory requirements; economic weakness, including inflation, or political instability in particular foreign economies and markets; compliance with tax, employment, immigration and labor laws for employees living or traveling abroad; foreign taxes, including withholding of payroll taxes; | |

| ● | differing payor reimbursement regimes, governmental payors or patient self-pay systems and price controls; | |

| ● | foreign currency fluctuations, which could result in increased operating expenses or reduced revenues, and other obligations incident to doing business or operating in another country; | |

| ● | workforce uncertainty in countries where labor unrest is more common than in the U.S.; | |

| ● | production shortages resulting from any events affecting raw material supply or manufacturing capabilities abroad; and | |

| ● | business interruptions resulting from geopolitical actions, including war and terrorism. |

Failure to obtain regulatory approval in international jurisdictions would prevent our product candidates from being marketed abroad.

In addition to regulations in the U.S., to market and sell Oxyglobin and Hemopure for any proposed new indication or our product candidates in the European Union, United Kingdom, many Asian countries and other jurisdictions, we must obtain separate regulatory approvals and comply with numerous and varying regulatory requirements. Approval by the FDA does not ensure approval by regulatory authorities in other countries or jurisdictions, and approval by one regulatory authority outside the U.S. does not ensure approval by regulatory authorities in other countries or jurisdictions or by the FDA. The regulatory approval process outside the U.S. generally includes all of the risks associated with obtaining FDA approval as well as risks attributable to the satisfaction of local regulations in foreign jurisdictions. The approval procedure varies among countries and can involve additional testing. The time required to obtain approval may differ substantially from that required to obtain FDA approval. We may not be able to obtain approvals from regulatory authorities outside the U.S. on a timely basis, if at all. Clinical trials accepted in one country may not be accepted by regulatory authorities in other countries. In addition, many countries outside the U.S. require that a product be approved for reimbursement before it can be approved for sale in that country. A product candidate that has been approved for sale in a particular country may not receive reimbursement approval in that country.

We may not be able to file for regulatory approvals and may not receive necessary approvals to commercialize our products in any additional markets. If we are unable to obtain approval of Oxyglobin and Hemopure for any proposed new indication or any of our current product candidates or any future product candidates we may pursue by regulatory authorities in the European Union, United Kingdom, Asia or elsewhere, the commercial prospects of that product may be significantly diminished, our business prospects could decline and this could materially adversely affect our business, results of operations and financial condition.

| 21 |

Even though our current primary indications of Oxyglobin and Hemopure received regulatory approval, they may still face future development and regulatory difficulties.

Even though we have obtained regulatory approval for certain indications for Oxyglobin and Hemopure in certain markets, and if we obtain approval of any product candidate or of any new indications of Oxyglobin and Hemopure in other markets, that approval is and/or would be subject to ongoing requirements by the FDA and comparable foreign regulatory authorities governing the manufacture, quality control, further development, labeling, packaging, storage, distribution, adverse event reporting, safety surveillance, import, export, advertising, promotion, recordkeeping and reporting of safety and other post-marketing information. These requirements include submissions of safety and other post-marketing information and reports, registration, as well as continued compliance by us and/or our Contract Manufacturing Organizations (“CMOs”) and CROs for any post-approval clinical trials that we may conduct. The safety profile of any product after approval continues to be closely monitored by the FDA and comparable foreign regulatory authorities. If the FDA or comparable foreign regulatory authorities become aware of new safety information after a product’s approval, they may require labeling changes or establishment of a risk evaluation and mitigation strategy, impose significant restrictions on such product’s indicated uses or marketing or impose ongoing requirements for potentially costly post-approval studies or post-market surveillance.

In addition, manufacturers of devices and their facilities are subject to continual review and periodic inspections by the FDA and other regulatory authorities for compliance with Current Good Manufacturing Practice, Good Clinical Practice, and other regulations. If we or a regulatory agency discover previously unknown problems with a product, such as adverse events of unanticipated severity or frequency, or problems with the facility where the product is manufactured, a regulatory agency may impose restrictions on that product, the manufacturing facility or us, including requiring recall or withdrawal of the product from the market or suspension of manufacturing. If we or our productor at the manufacturing facilities for our product fail to comply with applicable regulatory requirements, a regulatory agency may:

| ● | issue warning letters or untitled letters; | |

| ● | mandate modifications to promotional materials or require us to provide corrective information to healthcare practitioners; | |

| ● | require us to enter into a consent decree, which can include imposition of various fines, reimbursements for inspection costs, required due dates for specific actions and penalties for noncompliance; | |

| ● | seek an injunction or impose civil or criminal penalties or monetary fines; | |

| ● | suspend or withdraw regulatory approval; | |

| ● | suspend any ongoing clinical trials; | |

| ● | refuse to approve pending applications or supplements to applications filed by us; | |

| ● | suspend or impose restrictions on operations, including costly new manufacturing requirements; or | |

| ● | seize or detain products, refuse to permit the import or export of products, or require us to initiate a product recall. |