| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Date and Signatures Page

The effective date of this report is November 2, 2022. The report issuance date is January 31, 2023. The Qualified Persons (QPs) do not believe that material changes have occurred with the assumptions or base data from the effective dates to the report's date of issuance. See Appendix A, Feasibility Study Contributors and Professional Qualifications, for certificates of qualified persons. These certificates are considered the date and signature of this report in accordance with Form 43-101F1.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table of Contents

| Date and Signatures Page | ii |

| Table of Contents | iii |

| List of Figures and Illustrations | vii |

| List of Tables | x |

| 1 Summary | 1 |

| 1.1 Introduction | 1 |

| 1.2 Property Location, Description and Ownership | 1 |

| 1.3 Geology | 1 |

| 1.4 Deposit Types | 2 |

| 1.5 Exploration | 2 |

| 1.6 Drilling | 2 |

| 1.7 Sample Preparation, Analyses and Security | 3 |

| 1.8 Data Verification | 3 |

| 1.9 Metallurgical Testing | 4 |

| 1.10 Mineral Resources and Reserves | 5 |

| 1.11 Mine Methods | 6 |

| 1.12 Recovery Methods | 7 |

| 1.13 Infrastructure | 8 |

| 1.14 Market Studies and Contracts | 9 |

| 1.15 Capital and Operating Costs | 10 |

| 1.16 Financial Model | 12 |

| 1.17 Conclusions and Recommendations | 13 |

| 2 Introduction and Terms of Reference | 16 |

| 2.1 Sources of Information | 16 |

| 2.2 Description of Personal Inspections | 19 |

| 2.3 Units, Currency and Terms of Reference | 21 |

| 3 Reliance on Other Experts | 26 |

| 4 Property Description and Location | 27 |

| 4.1 Property Description | 27 |

| 4.2 Mineral Tenure | 30 |

| 4.3 Nature and Extent of Interest and Title | 32 |

| 4.4 Royalties, Rights and Payments | 33 |

| 4.5 Environmental Liabilities | 33 |

| 4.6 Permitting | 33 |

| 4.7 Other Factors or Risks | 34 |

| 4.8 Conclusions | 34 |

| 5 Accessibility, Climate, Local Resources, Infrastructure, and Physiography | 35 |

| 5.1 Physiography | 35 |

| 5.2 Accessibility | 35 |

| 5.3 Climate | 35 |

| 5.4 Local Resources | 37 |

| 5.5 Infrastructure | 37 |

| 5.6 Water Rights | 38 |

| 6 History | 39 |

| 6.1 Ownership History | 39 |

| 6.2 Exploration History | 39 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| 6.3 Historic Production from the Property | 40 |

| 7 Geological Setting and Mineralization | 41 |

| 7.1 Regional Geology | 41 |

| 7.2 Geologic History of the McDermitt Caldera | 42 |

| 7.3 Mineralization | 44 |

| 8 Deposit Types | 49 |

| 8.1 Lithium Mineralization | 49 |

| 8.2 Basis of Exploration | 49 |

| 9 Exploration | 51 |

| 9.1 Thacker Pass | 51 |

| 9.2 Additional Exploration | 53 |

| 10 Drilling | 54 |

| 10.1 Type and Extent of Drilling by LAC | 54 |

| 10.2 Additional Drilling in Thacker Pass Deposit | 58 |

| 10.3 Surveying | 59 |

| 10.4 Accuracy and Reliability of Drilling Results | 59 |

| 11 Sample Preparation, Analyses, and Security | 60 |

| 11.1 LAC Site Sample Preparation | 60 |

| 11.2 Laboratory Sample Preparation | 61 |

| 11.3 Analysis | 62 |

| 11.4 Density | 62 |

| 11.5 Quality Control | 67 |

| 11.6 Qualified Person Statement | 73 |

| 12 Data Verification | 74 |

| 12.1 Site Inspection | 74 |

| 12.2 Data Verification Procedures | 76 |

| 12.3 Drill Core and Geologic Logs | 76 |

| 12.4 Verification of Drill Hole Survey | 76 |

| 12.5 Verification of Analytical Data | 79 |

| 12.6 Geological and Block Modelling | 79 |

| 12.7 Mine Design and LOM Plan | 80 |

| 12.8 Data Adequacy | 81 |

| 13 Mineral Processing and Metallurgical Testing | 82 |

| 13.1 Ore Collection for Metallurgical Testing | 82 |

| 13.2 Metallurgical Test Work by Area | 88 |

| 13.3 Beneficiation and Leaching Variability Study | 113 |

| 13.4 Specific Gravity | 116 |

| 13.5 Metallurgical Test Work Conclusions | 117 |

| 14 Mineral Resource Estimates | 118 |

| 14.1 Thacker Pass Deposit | 118 |

| 14.2 Comments | 145 |

| 15 Mineral Reserve Estimates | 146 |

| 15.1 Pit Optimization | 146 |

| 15.2 Mineral Reserves and Cutoff Grade | 148 |

| 15.3 Waste | 150 |

| 15.4 Stripping Ratio | 150 |

| 15.5 Mineral Reserve Estimate - EIS Pit | 151 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| 15.6 Comments | 151 |

| 16 Mining Methods | 152 |

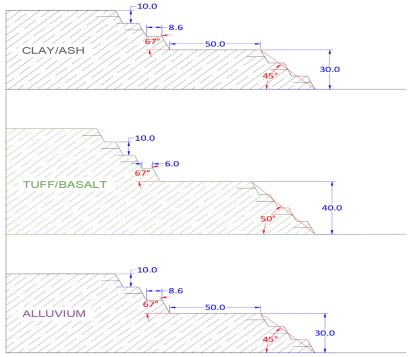

| 16.1 Pit Design | 152 |

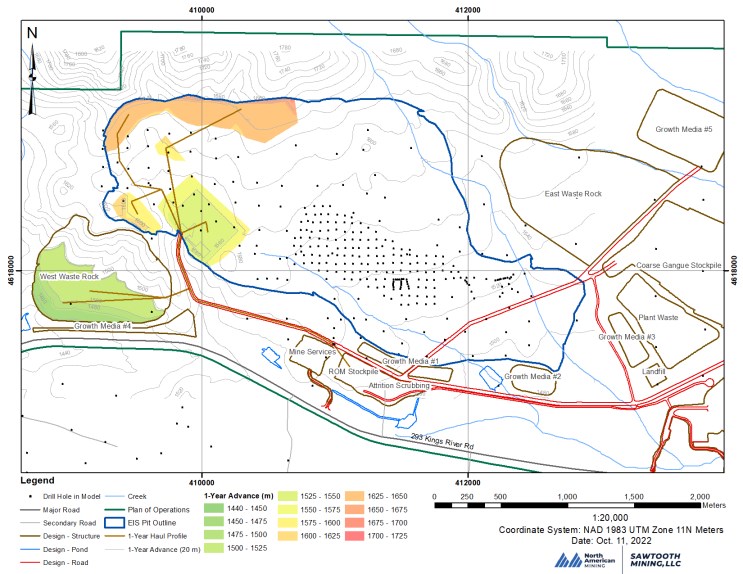

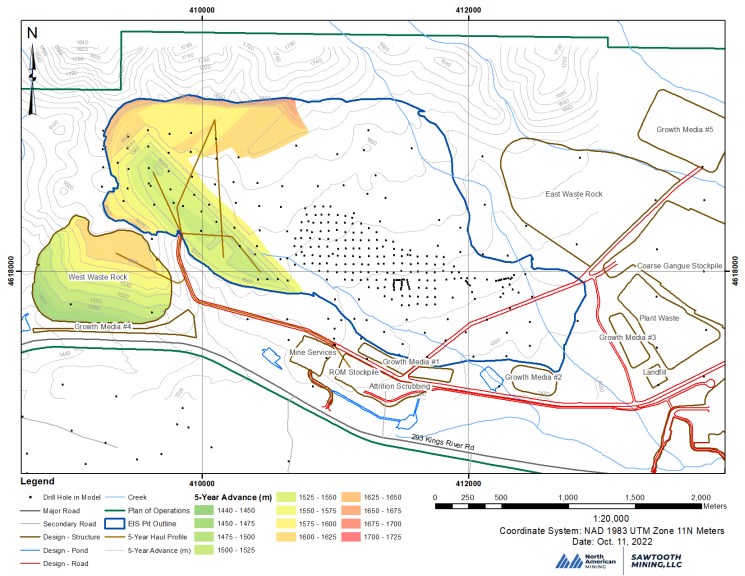

| 16.2 Mine Plan | 153 |

| 16.3 Mining Operations | 162 |

| 16.4 Equipment Selection | 164 |

| 16.5 Personnel Requirements | 166 |

| 16.6 Fuel | 167 |

| 16.7 Drilling and Blasting | 167 |

| 16.8 Dewatering | 169 |

| 17 Recovery Methods | 170 |

| 17.1 General Description | 170 |

| 17.2 Process Design Criteria | 172 |

| 17.3 Process Description | 176 |

| 17.4 Reagents | 182 |

| 17.5 Plant Water | 185 |

| 17.6 Power | 186 |

| 17.7 Air Service | 187 |

| 17.8 Quality Control | 188 |

| 17.9 Sampling | 188 |

| 17.10 Auxiliary Systems | 188 |

| 17.11 Process Control Philosophy | 189 |

| 18 Project Infrastructure | 190 |

| 18.1 Overall Site General Arrangement | 190 |

| 18.2 Process Plant General Arrangement | 190 |

| 18.3 Reagents, Consumables and Shipping | 191 |

| 18.4 Ancillary Buildings | 191 |

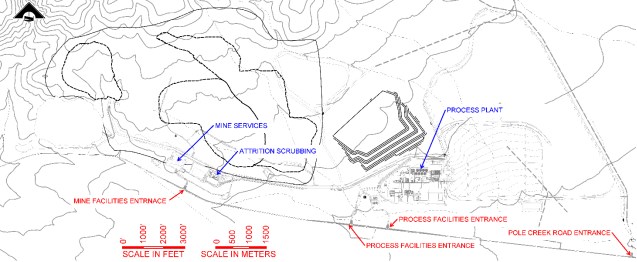

| 18.5 Site Access | 193 |

| 18.6 Raw Material Logistics | 195 |

| 18.7 Power Supply | 196 |

| 18.8 Sulfuric Acid Production | 202 |

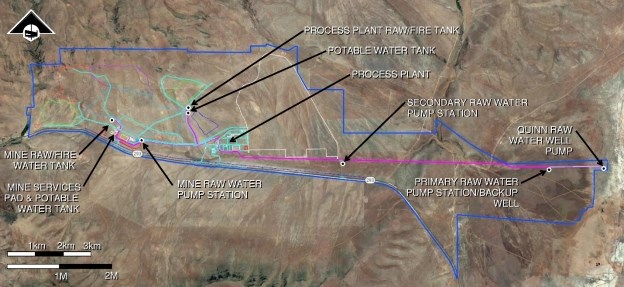

| 18.9 Water Supply | 203 |

| 18.10 Waste Rock and Tailings | 204 |

| 19 Market Studies and Contracts | 208 |

| 19.1 2021 and 2022 Synopsis | 208 |

| 19.2 Supply and Demand Forecast | 208 |

| 19.3 Pricing | 209 |

| 19.4 Pricing Forecast | 209 |

| 19.5 Contracts | 210 |

| 19.6 Qualified Person Statement | 210 |

| 20 Environmental Studies, Permitting, and Social or Community Impact | 211 |

| 20.1 Introduction | 211 |

| 20.2 Permitting Pre-Planning Process | 211 |

| 20.3 Federal, State, and Local Regulatory Permitting Requirements | 213 |

| 20.4 Summary Schedule for Permitting, Approvals, and Construction | 217 |

| 20.5 Current Permitting Status | 217 |

| 20.6 Community Engagement | 217 |

| 20.7 Environmental Baseline Studies | 220 |

| 20.8 Waste Rock, Gangue, and Tailings Facility Management | 228 |

| 20.9 Social or Community Impacts | 230 |

| 20.10 Mine Reclamation and Closure | 231 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| 21 Capital and Operating Costs | 233 |

| 21.1 Capital Cost Estimate | 233 |

| 21.2 Sustaining Capital Costs | 244 |

| 21.3 Operating Cost Estimate | 247 |

| 22 Economic Analysis | 262 |

| 22.1 Introduction | 262 |

| 22.2 Methodology | 262 |

| 22.3 Input Data | 263 |

| 22.4 Cash Flow | 269 |

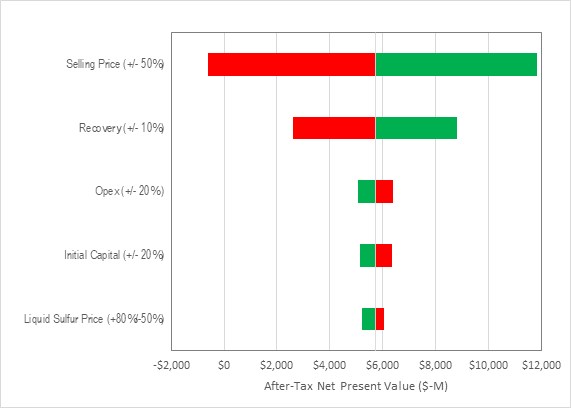

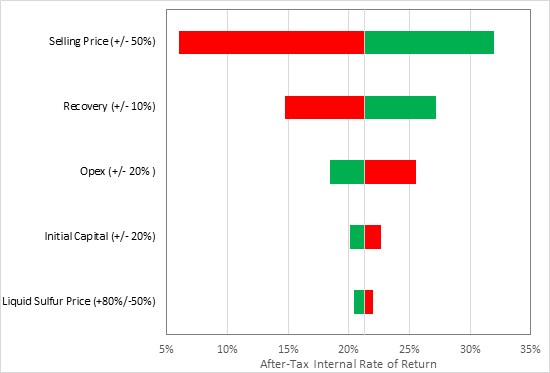

| 22.5 Sensitivity Analysis | 273 |

| 23 Adjacent Properties | 276 |

| 24 Other Relevant Data and Information | 277 |

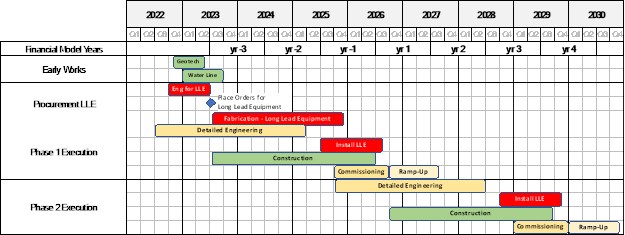

| 24.1 Project Execution Plan | 277 |

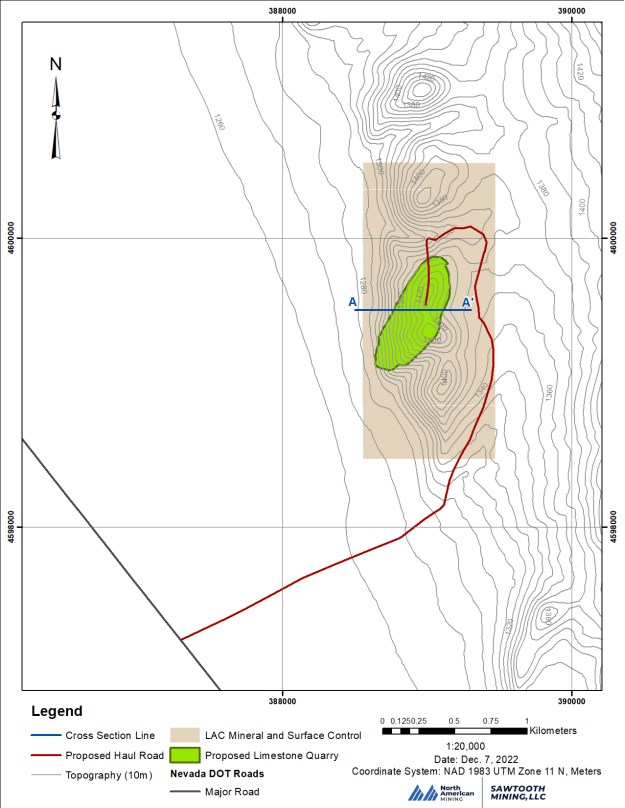

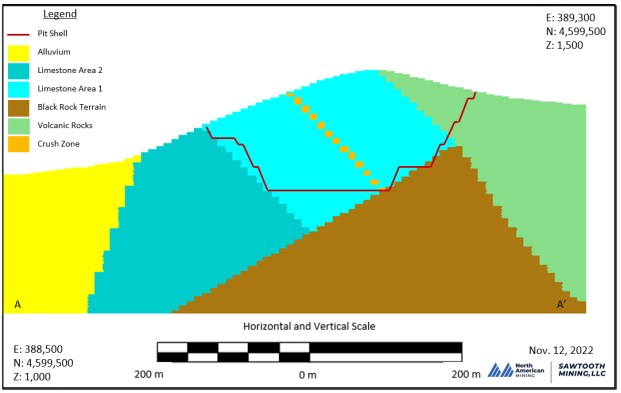

| 24.2 Limestone Quarry | 280 |

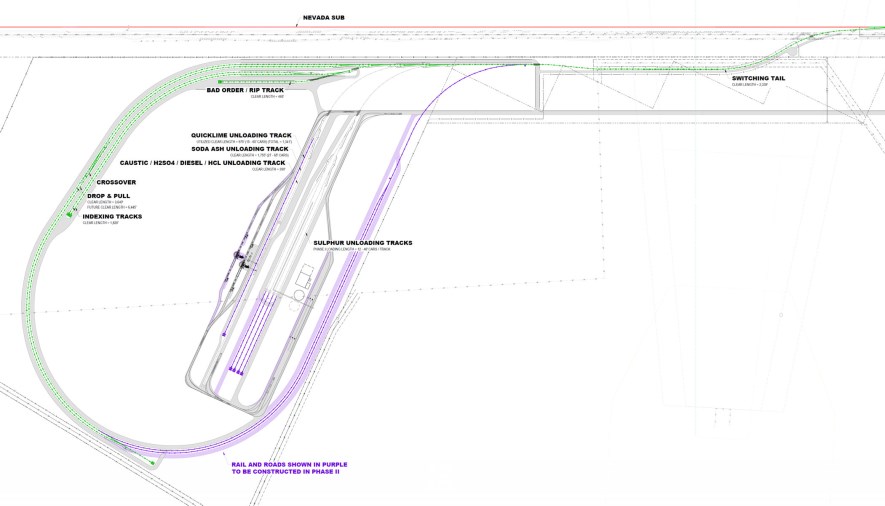

| 24.3 Transload Facility | 285 |

| 25 Interpretation and Conclusions | 290 |

| 25.1 Mineral Resource and Mineral Reserve Estimate | 290 |

| 25.2 Mining | 290 |

| 25.3 Infrastructure | 291 |

| 25.4 Environment | 291 |

| 25.5 Economics | 291 |

| 25.6 Metallurgy | 292 |

| 26 Recommendations | 295 |

| 26.1 Environmental Permitting | 295 |

| 26.2 Mining | 295 |

| 26.3 Exploration | 295 |

| 26.4 Metallurgical Testing | 296 |

| 26.5 Infrastructure | 298 |

| 26.6 Limestone Quarry | 298 |

| 26.7 Execution Strategy Impact | 298 |

| 27 References | 300 |

| Appendix A - Certificates of Qualified Persons | 309 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

List of Figures and Illustrations

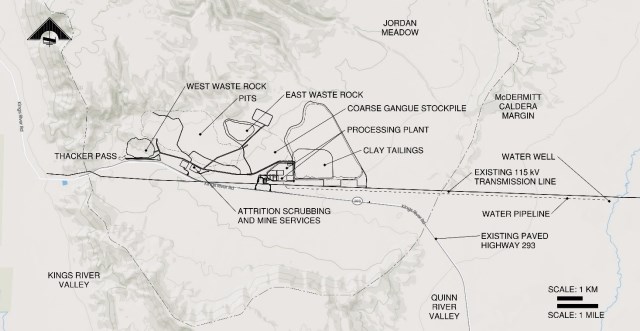

| Figure 1-1 | Overall Site General Arrangement | 8 |

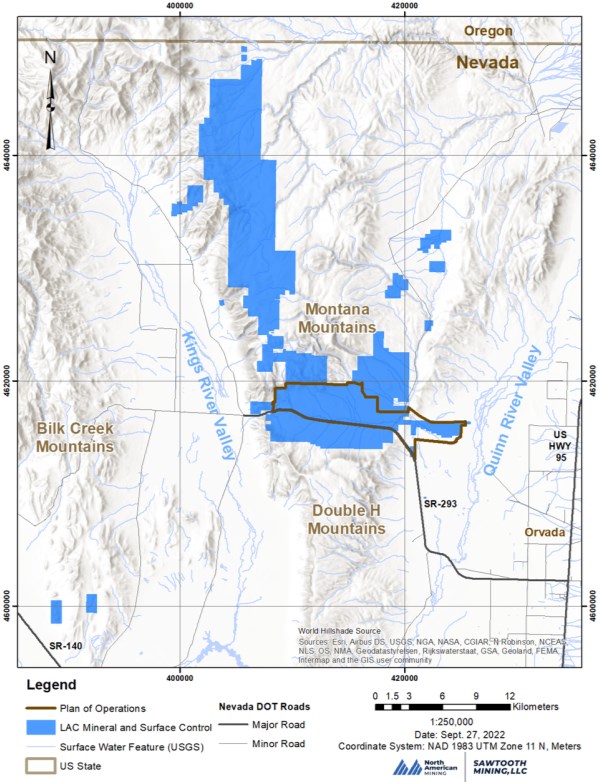

| Figure 4-1 | Regional Location Map | 28 |

| Figure 4-2 | Map of Lithium Americas Corp. Mineral and Surface Control in the Vicinity of the Thacker Pass Project | 29 |

| Figure 5-1 | Photograph of the On-Site Meteorological Station, Including Tower, Solar Power Station, and Security Fence | 36 |

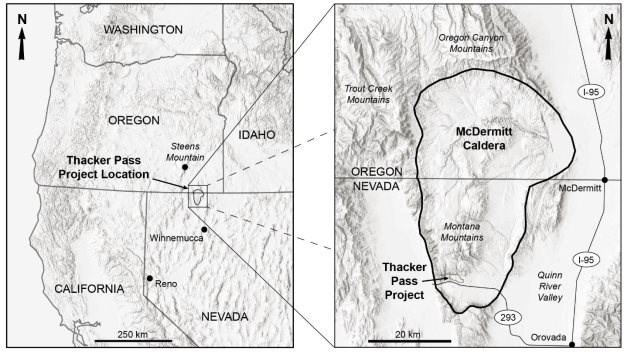

| Figure 7-1 | Regional Map Showing the Location of the McDermitt Caldera in the Western US | 42 |

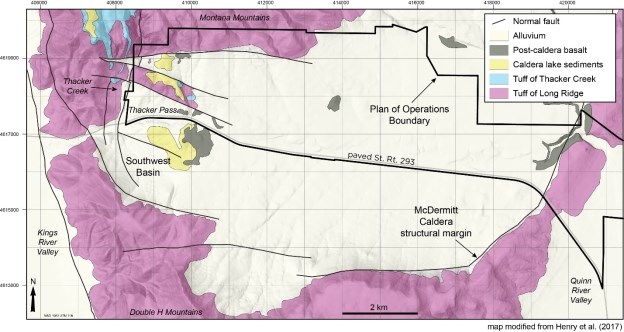

| Figure 7-2 | Simplified Geological Map of the Southern Portion of the McDermitt Caldera and the Thacker Pass Project | 43 |

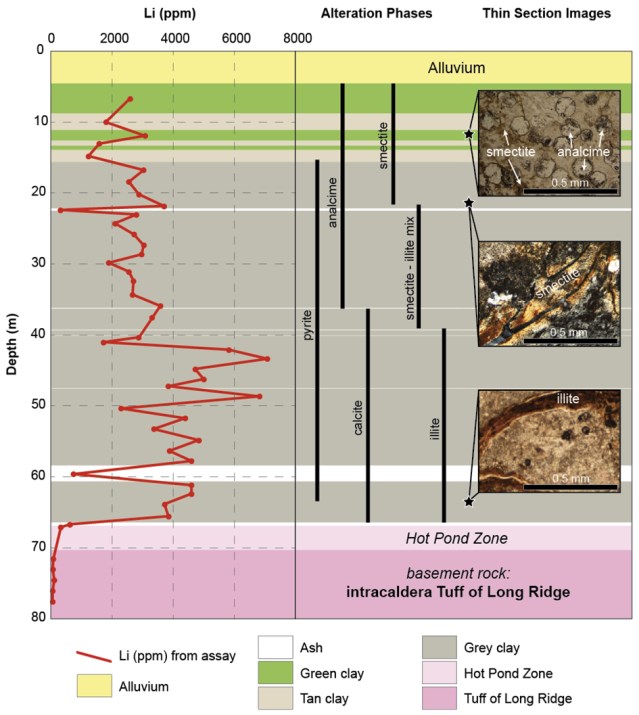

| Figure 7-3 | Interpreted and Simplified Sample Log for Drill Hole WLC-043, Li Assay Data, Alteration Phases Identified by X-ray Diffraction, and Thin Section Imagery | 45 |

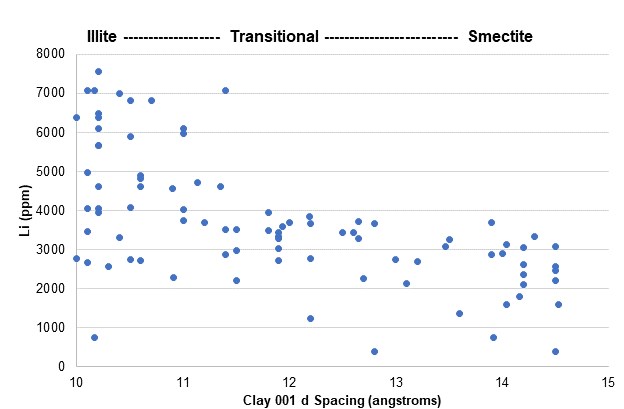

| Figure 7-4 | Assay Lithium Content Plotted Against Clay X-Ray Diffraction Data from Drill Holes WLC-043, WLC-006, and WLC-067 | 47 |

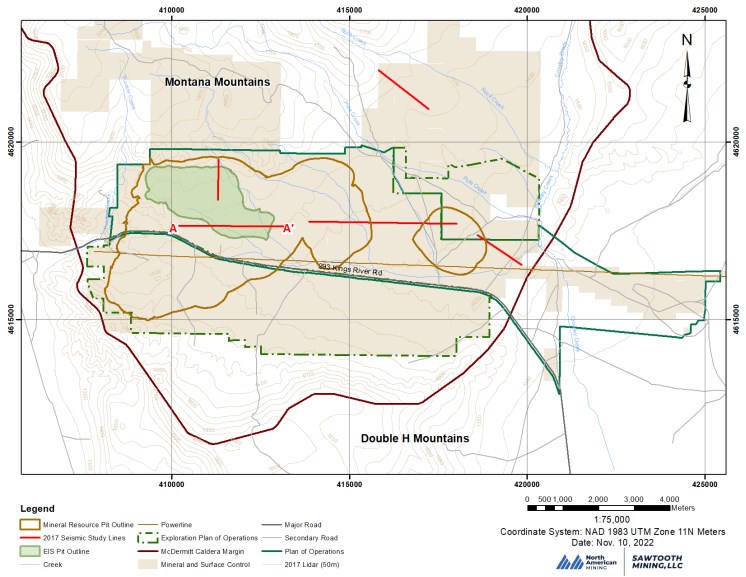

| Figure 9-1 | Locations of Seismic Surveys Conducted in 2017 | 52 |

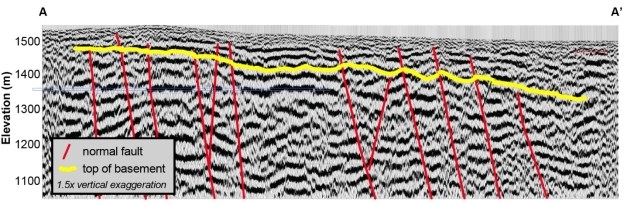

| Figure 9-2 | Results from one of the Seismic Test Lines (A-A') | 53 |

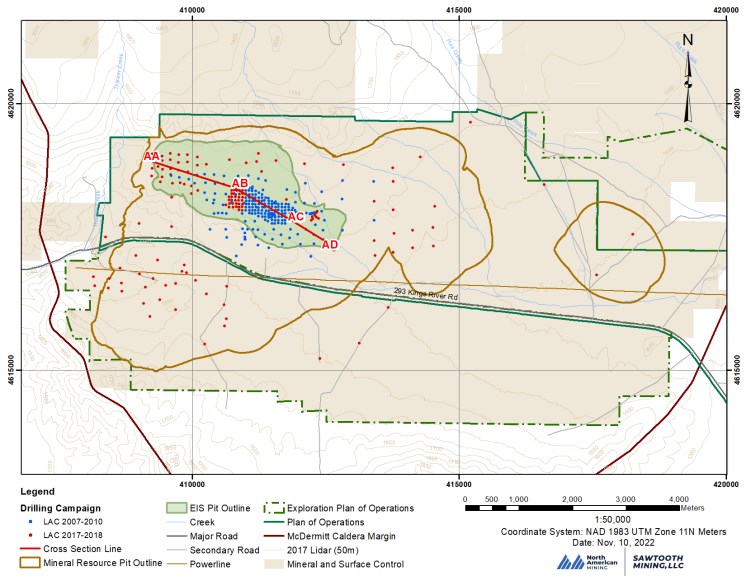

| Figure 10-1 | Drill Hole Map of Thacker Pass Deposit | 56 |

| Figure 10-2 | Photograph of Core after Geologic Logging | 57 |

| Figure 11-1 | Half Core Sawed by a Diamond Blade | 60 |

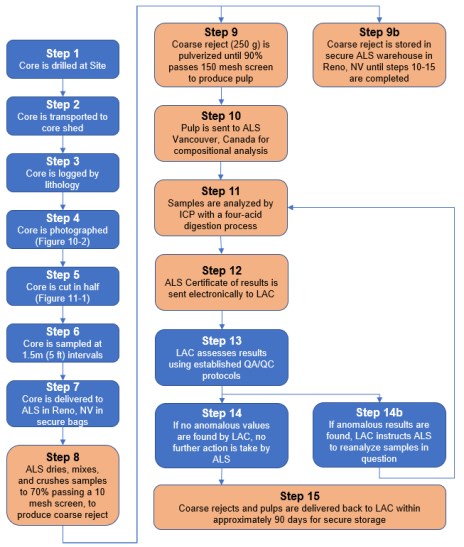

| Figure 11-2 | Workflow Diagram for Geological Samples | 61 |

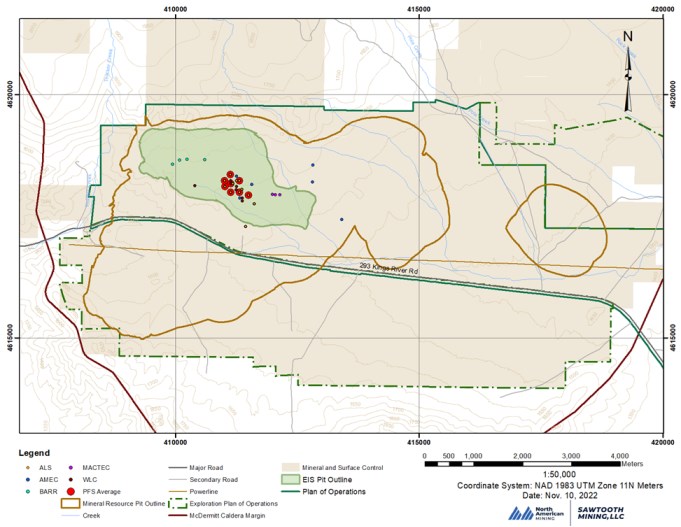

| Figure 11-3 | Dry Bulk Density Sample Locations | 65 |

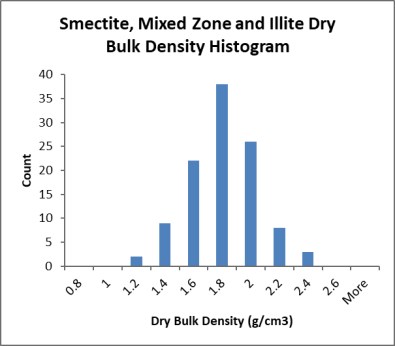

| Figure 11-4 | Smectite, Mixed Zone and Illite Dry Bulk Density Histogram from MacTec (2008), AMEC (2011), WLC (2010-2011), ALS (2010-2011), and BARR (2019) Geotech Studies | 66 |

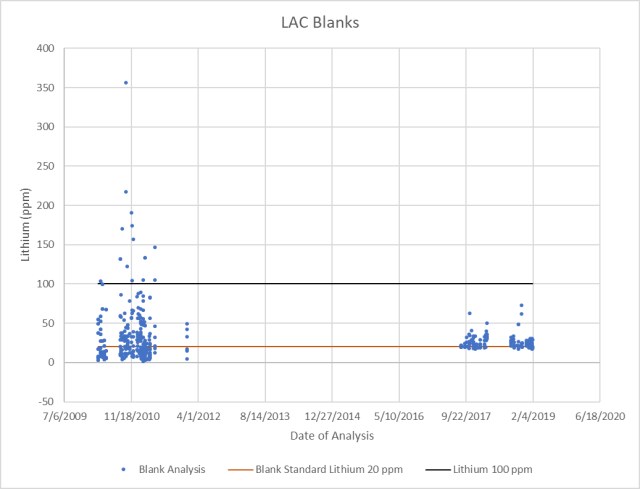

| Figure 11-5 | LAC Blank Results | 68 |

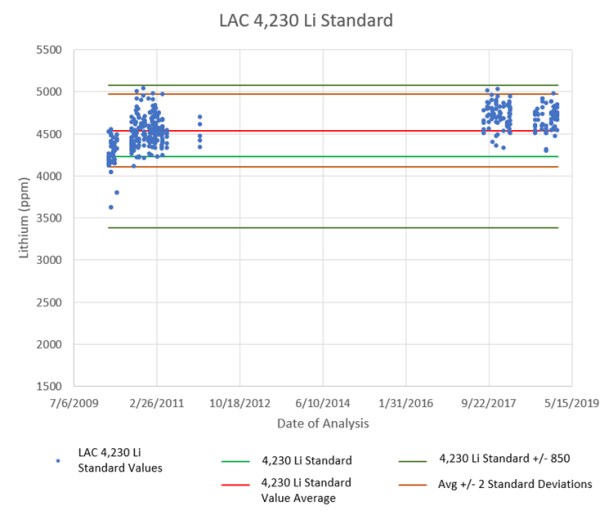

| Figure 11-6 | LAC Drilling QA/QC Results (4,230 Li Standard) | 70 |

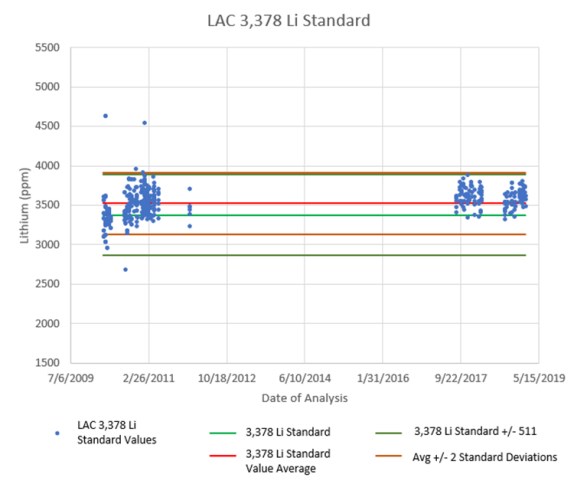

| Figure 11-7 | LAC Drilling QA/QC Results (3,378 Li Standard) | 71 |

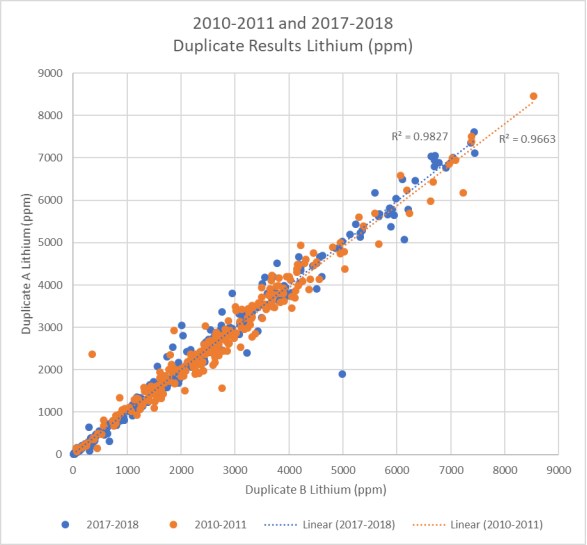

| Figure 11-8 | LAC Drilling Duplicate Results | 72 |

| Figure 12-1 | Site Inspection Pictures | 75 |

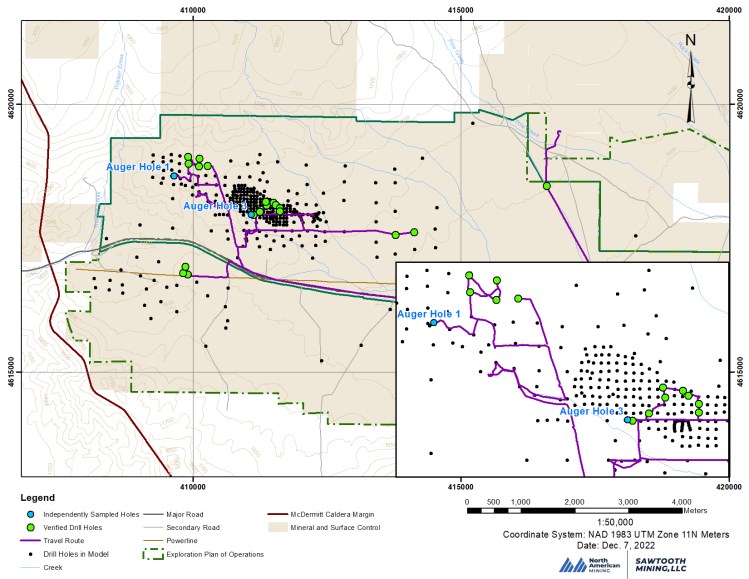

| Figure 12-2 | Drill Hole Verification Locations | 78 |

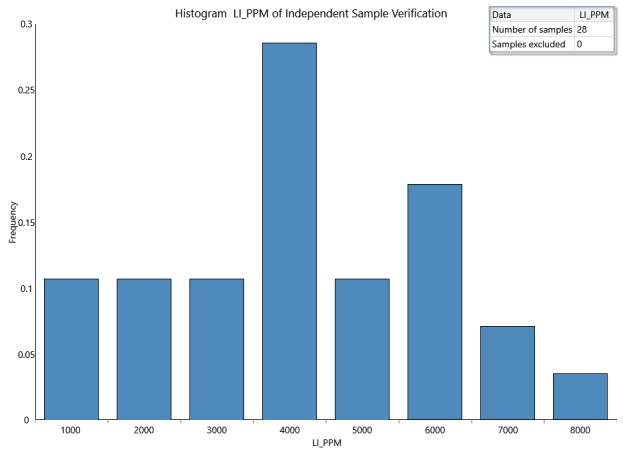

| Figure 12-3 | Independent Verification of Lithium Grades Distribution | 79 |

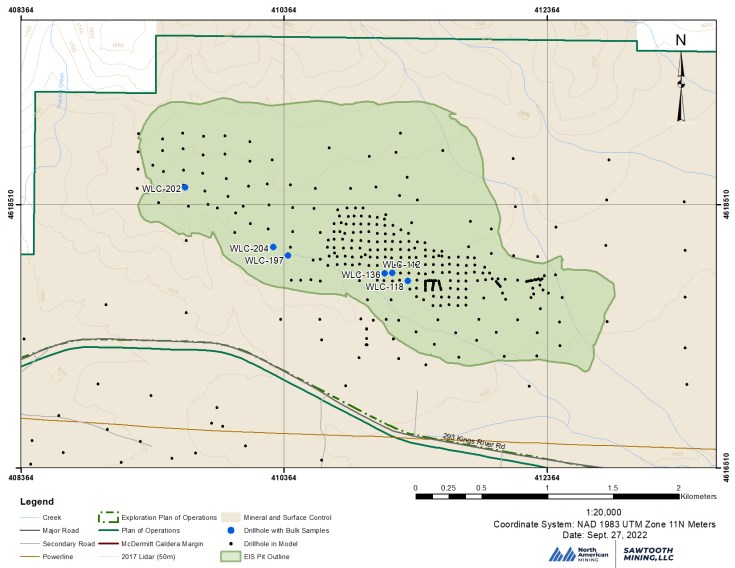

| Figure 13-1 | Bulk sample drill hole locations (WLC-202, WLC-204, WLC-197, WLC-136, WLC-112 and WLC-118) | 84 |

| Figure 13-2 | Bulk material sampling | 85 |

| Figure 13-3 | Sample Locations for Leach Variability Study | 87 |

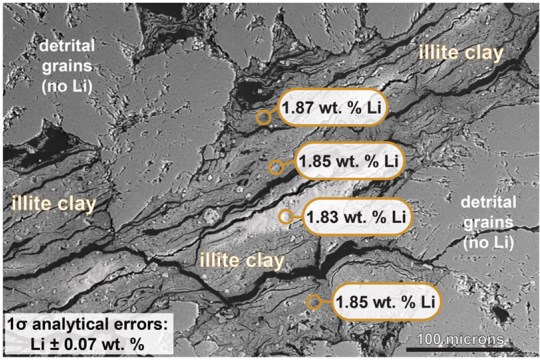

| Figure 13-4 | Lithium distribution in clay and gangue (SHRIMP analysis) | 89 |

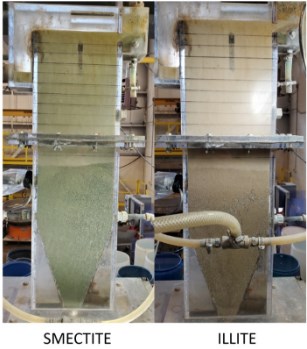

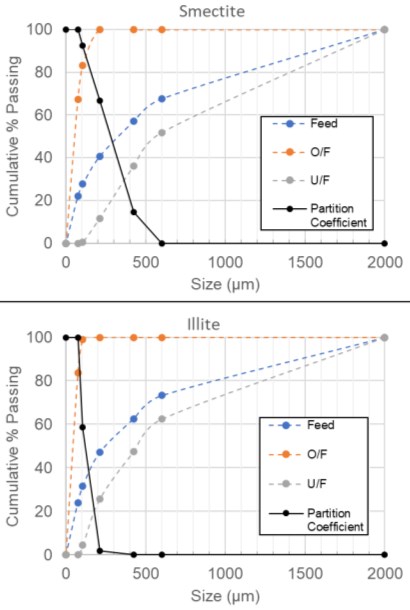

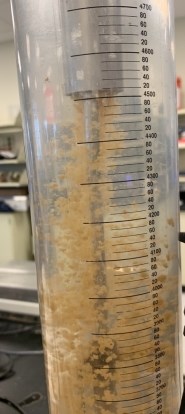

| Figure 13-5 | Smectite and illite fines separation in a pilot crossflow separator | 92 |

| Figure 13-6 | PSD's and partition coefficients of illite and smectite in the hydraulic classifier | 93 |

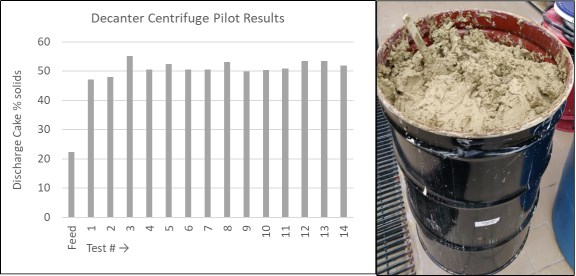

| Figure 13-7 | Pilot decanter centrifuge results | 95 |

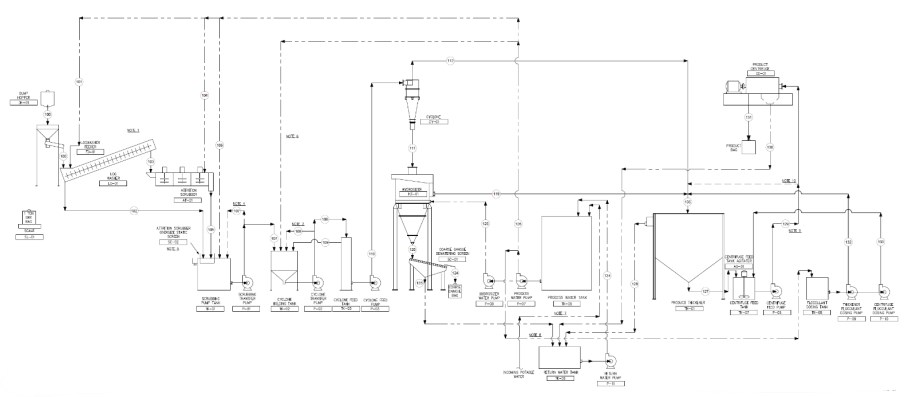

| Figure 13-8 | Large Scale Beneficiation Pilot Plant Process Flow Diagram | 97 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| Figure 13-9 | Log Washer and Attrition Scrubber | 98 |

| Figure 13-10 | Primary Cyclone, Hydraulic Classifier and Dewatering Screen | 98 |

| Figure 13-11 | Thickener and Decanter Centrifuge | 99 |

| Figure 13-12 | Coarse Gangue Rejection | 100 |

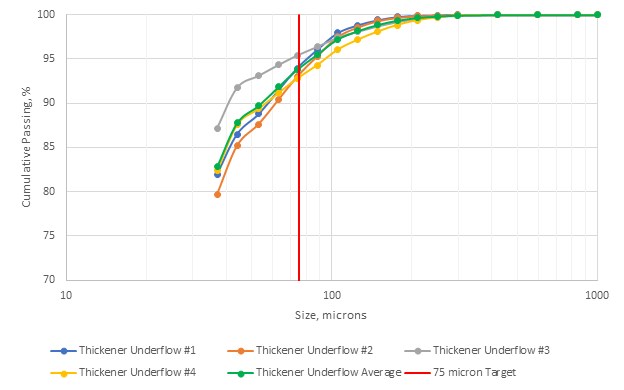

| Figure 13-13 | Campaign #3 Thickener Underflow (50% Smectite / 50% Illite) | 101 |

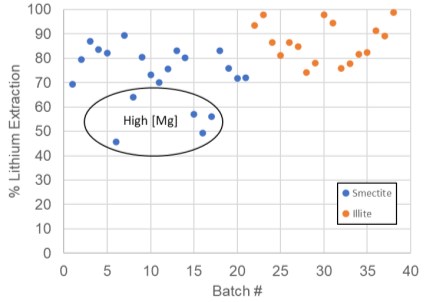

| Figure 13-14 | Large batch lithium leach extraction, Li ≥ 2,500 ppm, 05 acid dose | 102 |

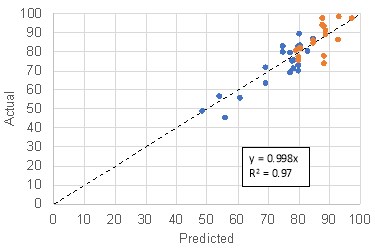

| Figure 13-15 | Actual lithium leach extraction percentage vs model prediction | 103 |

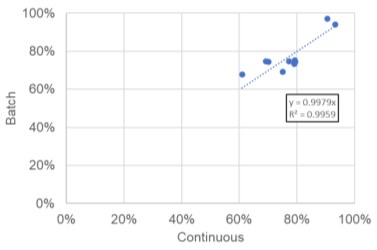

| Figure 13-16 | Continuous v batch lithium leach extraction | 104 |

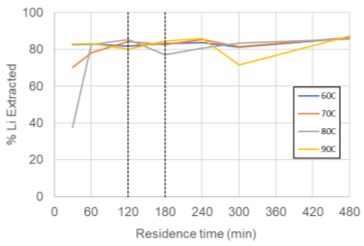

| Figure 13-17 | Lithium leach kinetics at various temperatures | 104 |

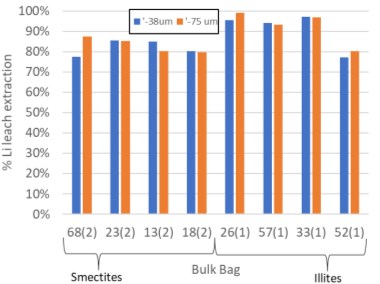

| Figure 13-18 | Lithium leach extractions for 75 µm and 38 µm particle sizes | 105 |

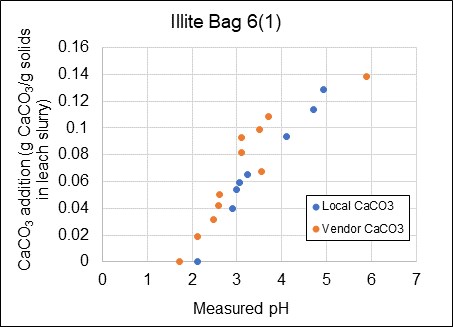

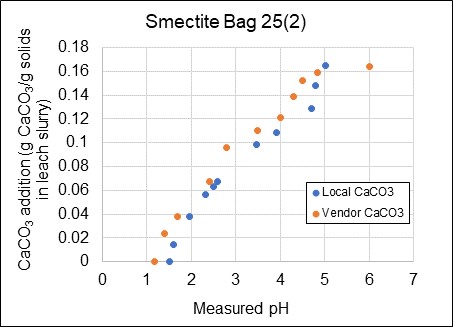

| Figure 13-19 | Local CaCO3 & vendor purchased comparison of pH vs limestone addition | 107 |

| Figure 13-20 | Pilot membrane filter press and resultant filter cake | 108 |

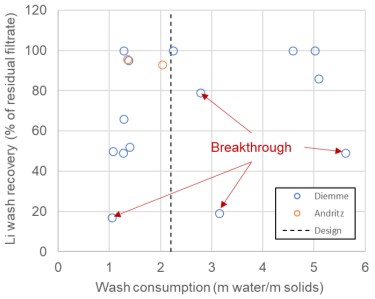

| Figure 13-21 | Wash consumption vs lithium wash recovery tests | 109 |

| Figure 13-22 | Dynamic Thickener Testing at FLSmidth | 110 |

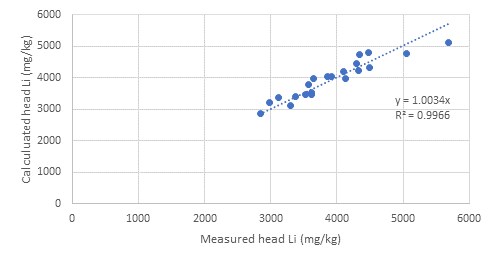

| Figure 13-23 | Calculated Versus Measured Head Grade for Leach Testing | 114 |

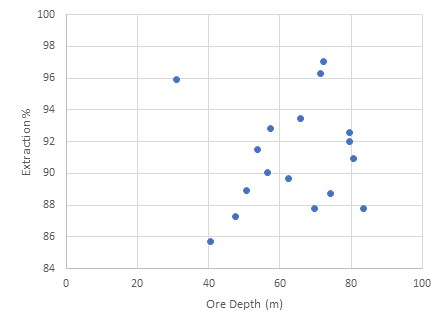

| Figure 13-24 | Ore Depth (m) Versus Li Extraction (%) | 115 |

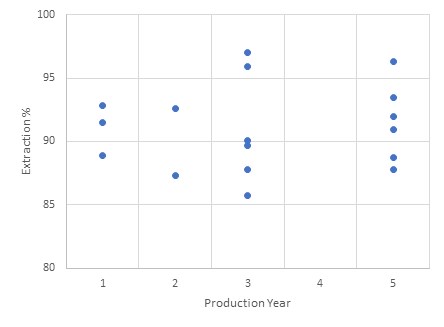

| Figure 13-25 | Mine Plan Year Versus Li Extraction (%) | 115 |

| Figure 13-26 | Comparison of Measured Versus Predicted Extraction | 116 |

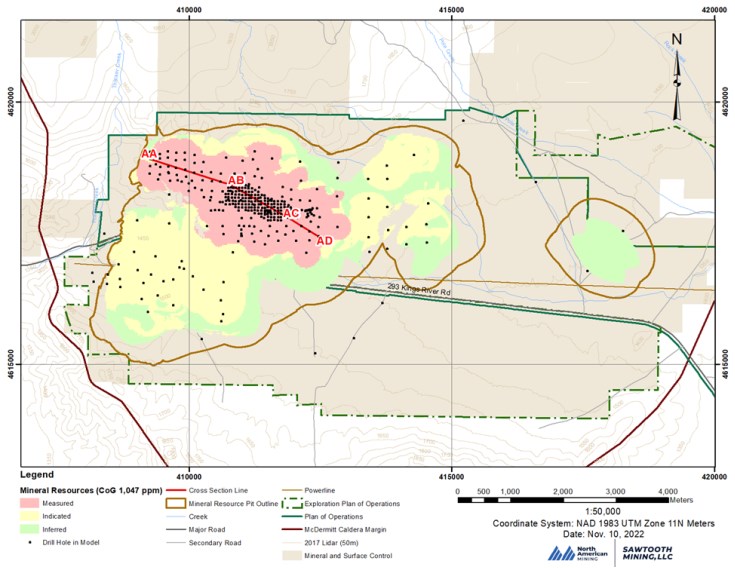

| Figure 14-1 | Drilling Utilized for the Resource Estimate | 119 |

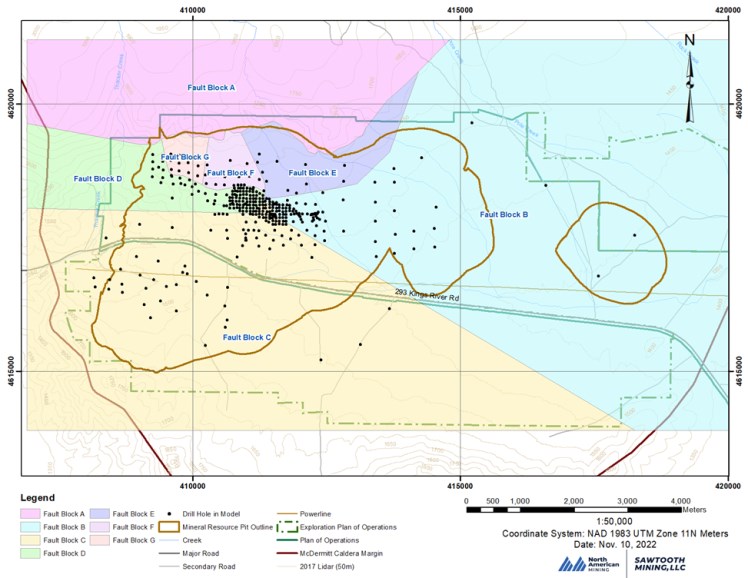

| Figure 14-2 | Seven Fault Blocks Zones Used for Grade Estimation for the Thacker Pass Deposit | 121 |

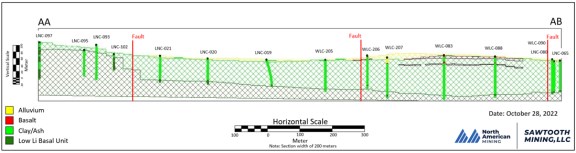

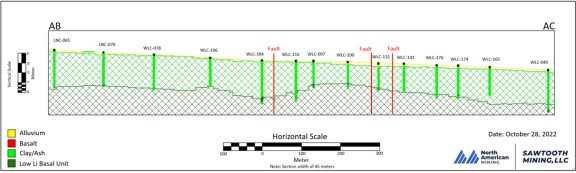

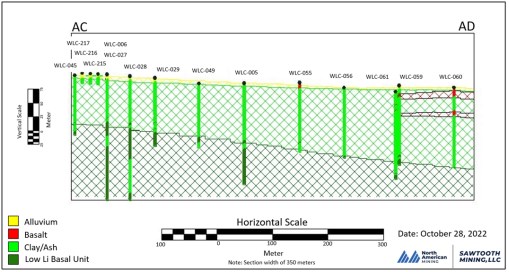

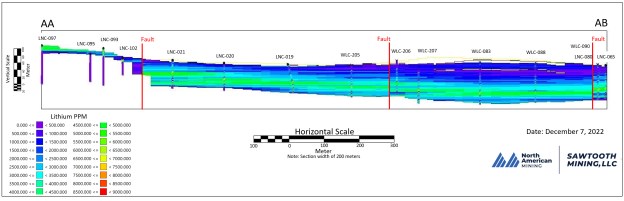

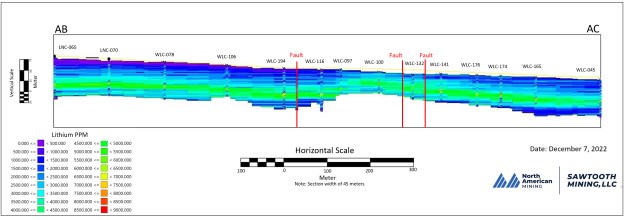

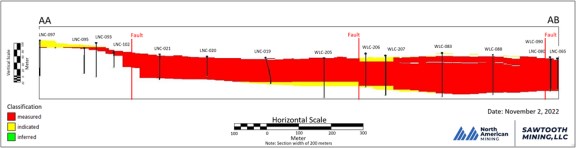

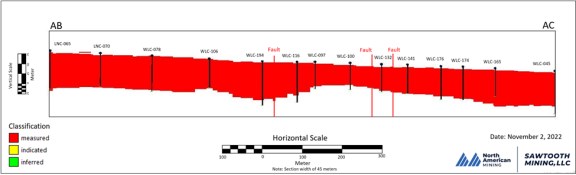

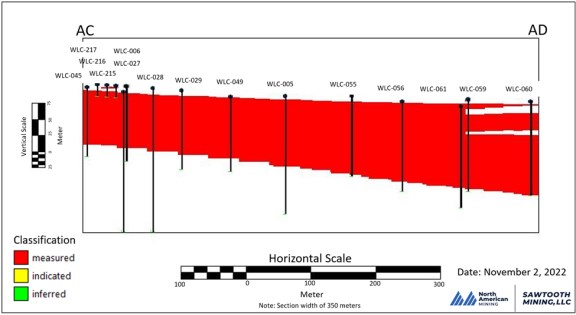

| Figure 14-3 | Lithological Cross-Sectional Views | 122 |

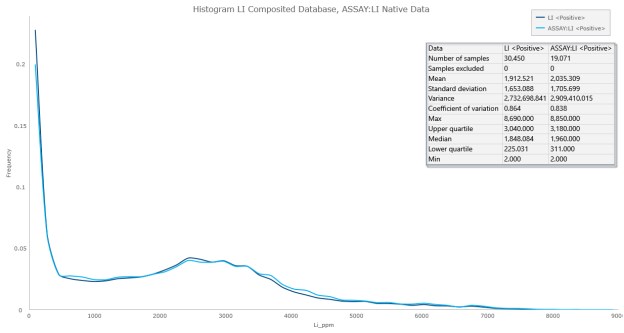

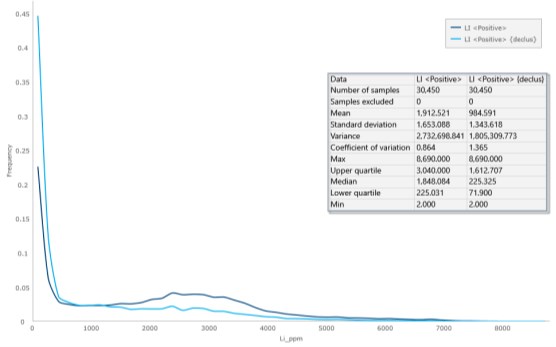

| Figure 14-4 | Histogram of Native Lithium Grade Versus Composited Database Lithium Grade | 125 |

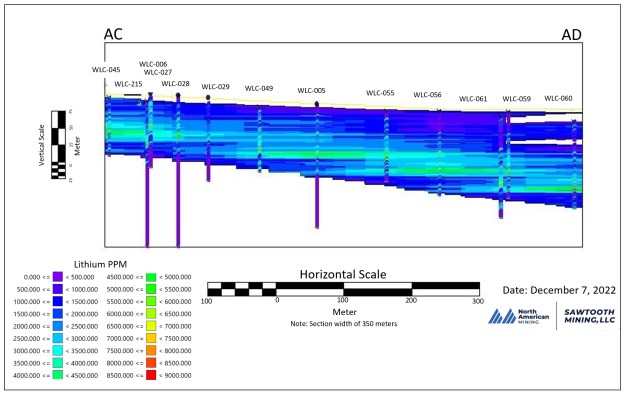

| Figure 14-5 | Mineralized Zone Cross-Sections | 126 |

| Figure 14-6 | Histogram of Composited Database Lithium Grade Versus Cell Declustered Lithium Grade | 127 |

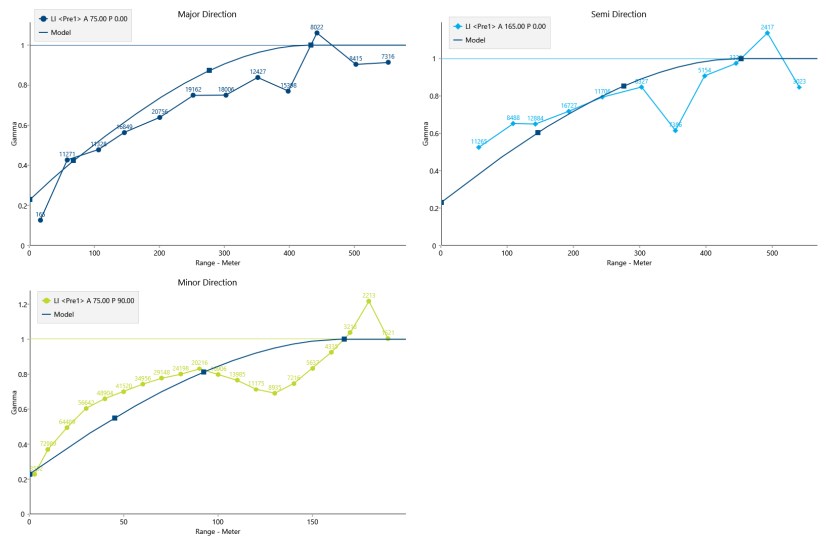

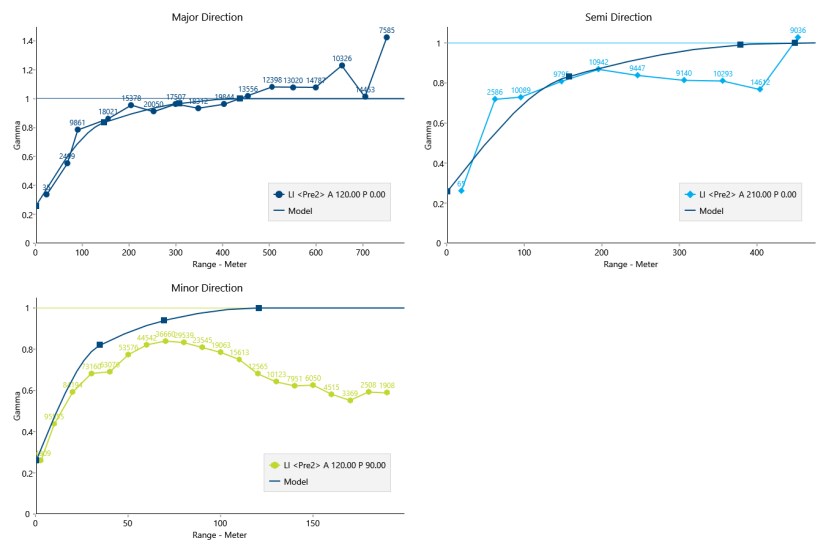

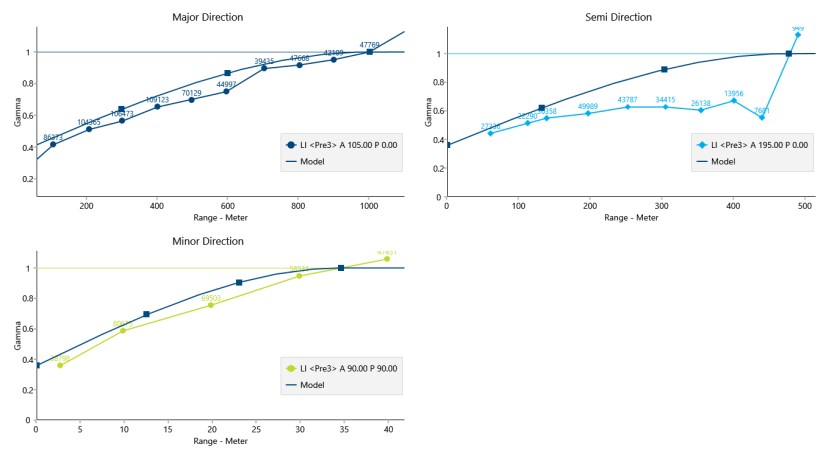

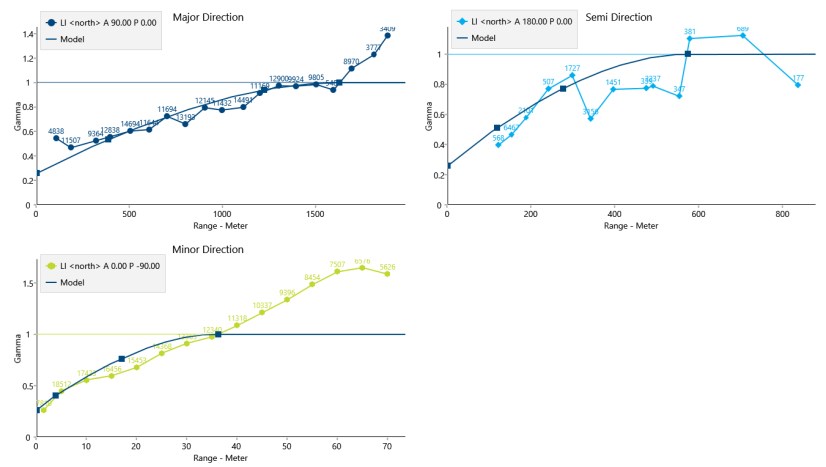

| Figure 14-7 | Block B, C, D, E, F, and G Omnidirectional Variograms in the Sub-Horizontal Plane and Downhole Variogram | 129 |

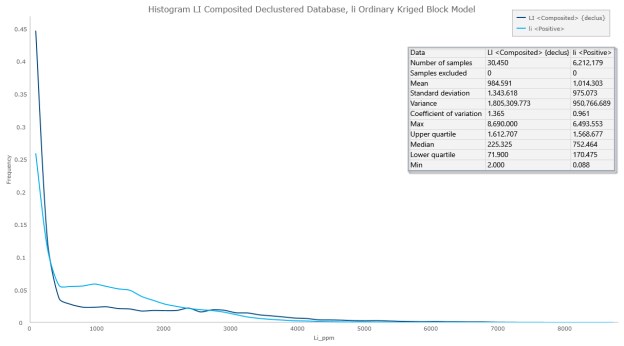

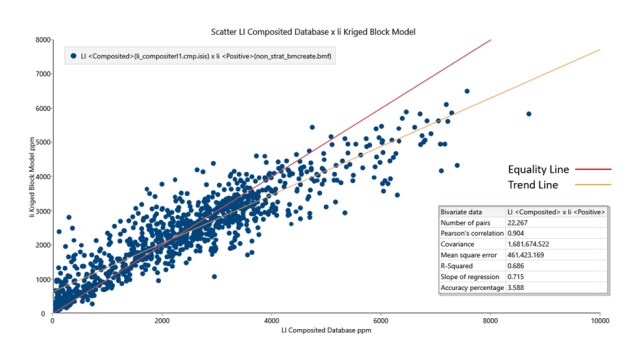

| Figure 14-8 | Ordinary Kriged Model vs Composited Declustered Database Histogram | 133 |

| Figure 14-9 | Scatter Plot of Lithium from the Block Model Versus the Composited Database | 134 |

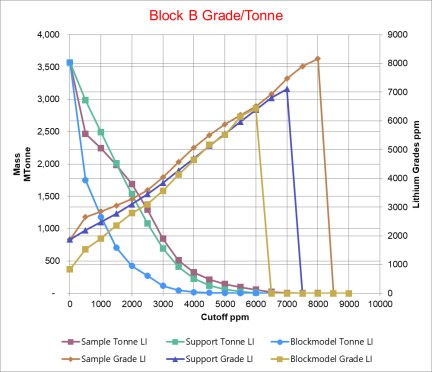

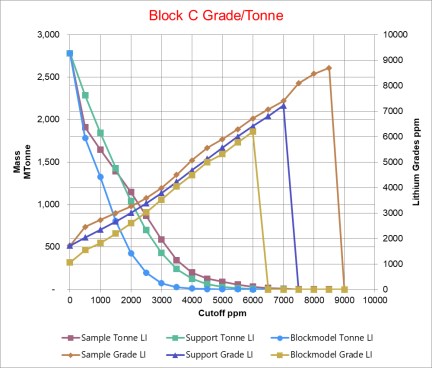

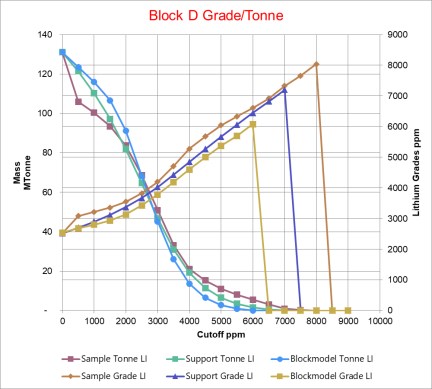

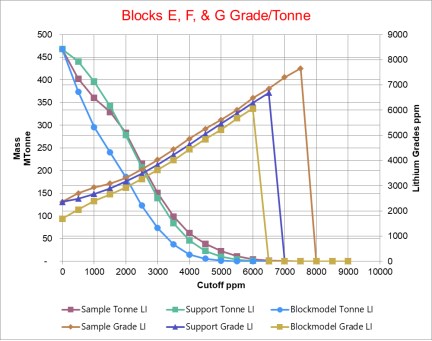

| Figure 14-10 | HERCO Plots by Domain | 135 |

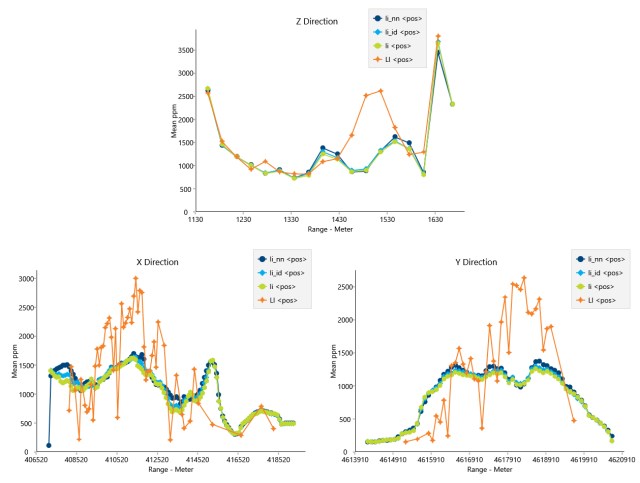

| Figure 14-11 | Swath Plot Comparison of Lithium Grades | 137 |

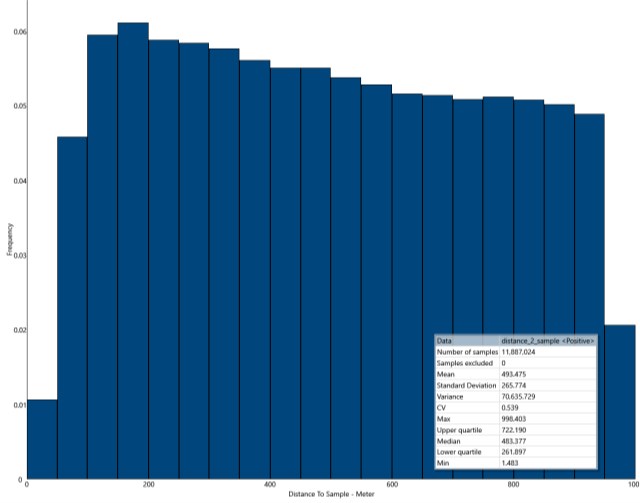

| Figure 14-12 | Histogram Distance to Sample | 140 |

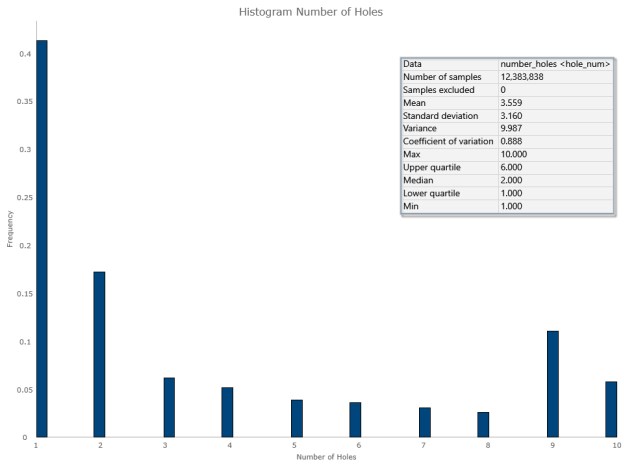

| Figure 14-13 | Histogram Number of Holes | 141 |

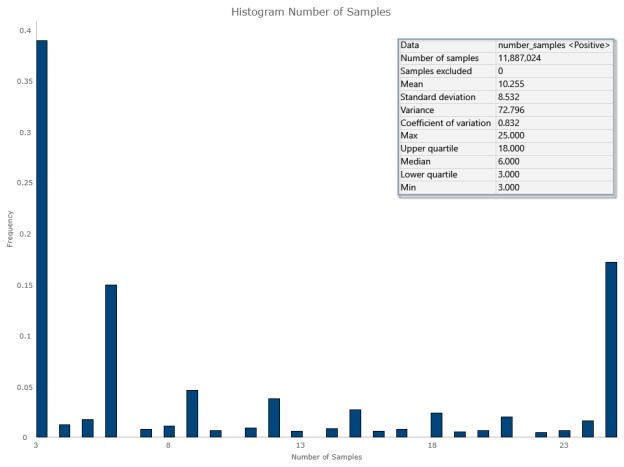

| Figure 14-14 | Histogram Number of Samples | 142 |

| Figure 14-15 | Classified Resource Block Model | 143 |

| Figure 14-16 | Cross-Sectional View of Classified Block Model | 144 |

| Figure 15-1 | EIS Pit Shell | 147 |

| Figure 16-1 | Highwall Angles | 153 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

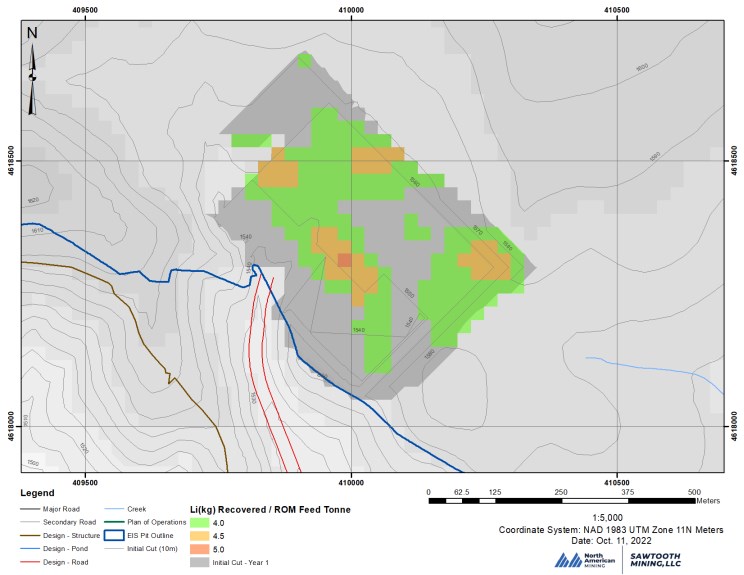

| Figure 16-2 | Kilograms of Lithium Recovered per tonne of ROM Feed at Initial Cut | 154 |

| Figure 16-3 | Initial Cut | 156 |

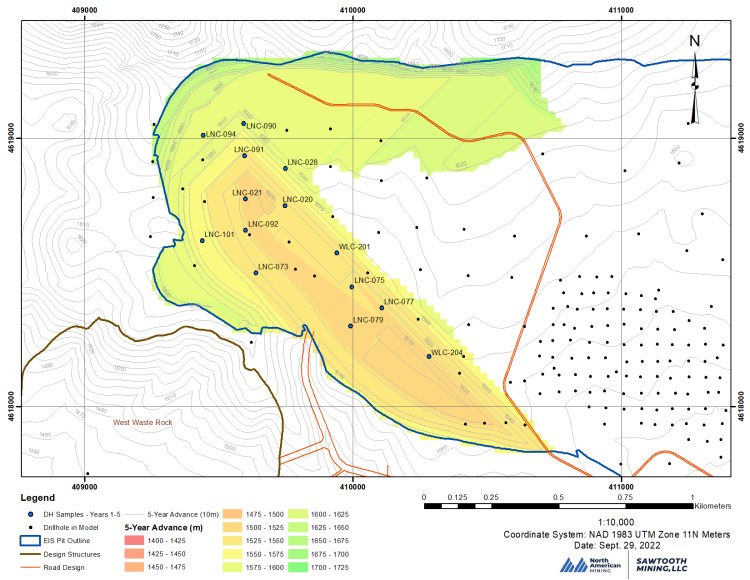

| Figure 16-4 | Five Year Advance (Including Cross Pit Ramps) | 157 |

| Figure 16-5 | 10 Year Advance | 158 |

| Figure 16-6 | 20 Year Advance | 159 |

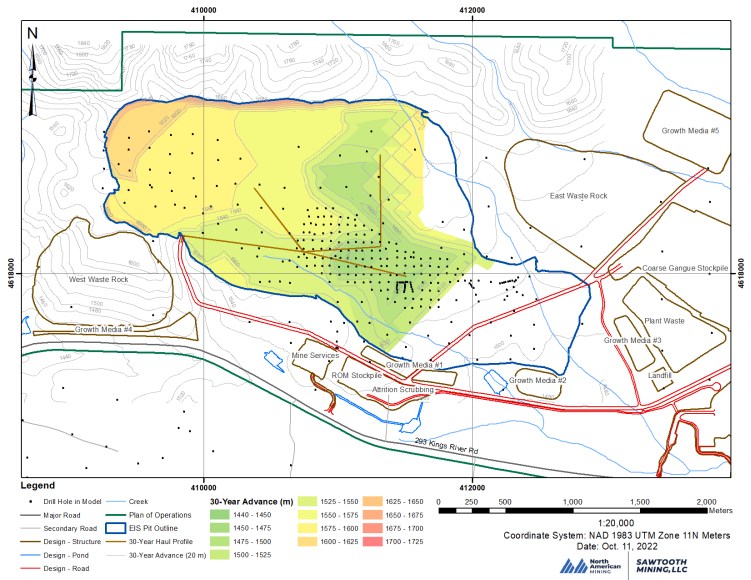

| Figure 16-7 | 30 Year Advance | 160 |

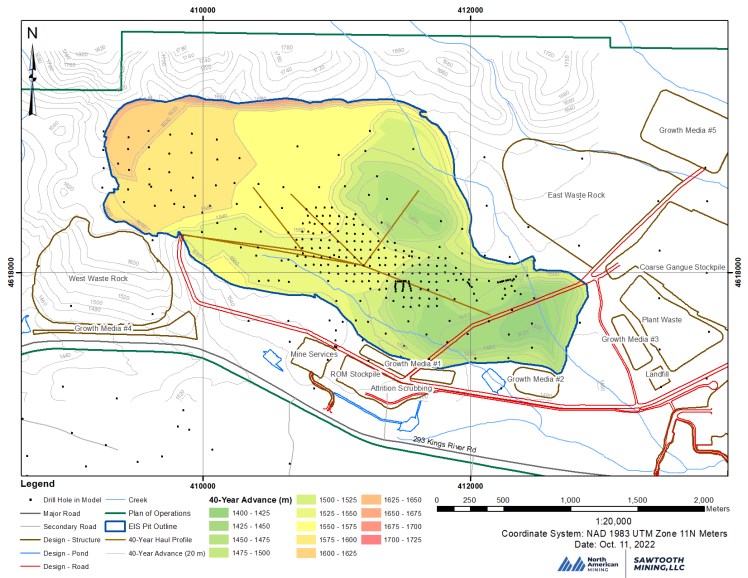

| Figure 16-8 | 40 Year Advance | 161 |

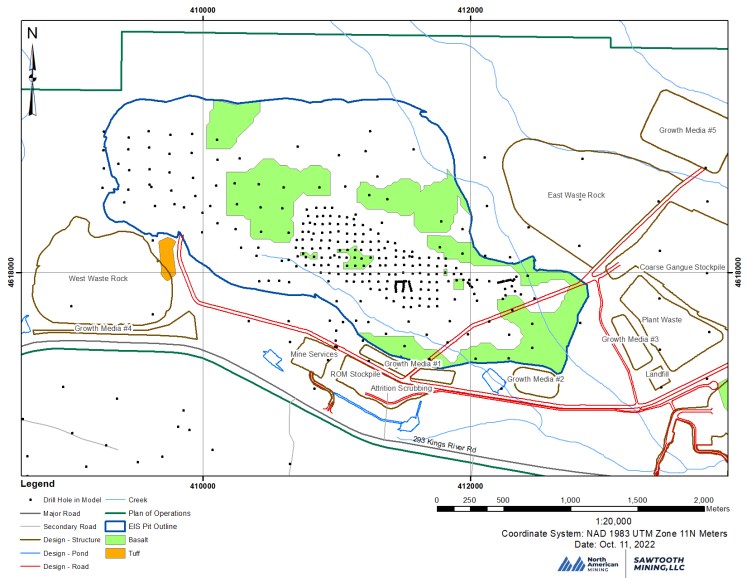

| Figure 16-9 | Basalt and tuff zones near the pit area | 168 |

| Figure 17-1 | Overall Simplified Process Flowsheet | 171 |

| Figure 18-1 | Overall Site General Arrangement | 190 |

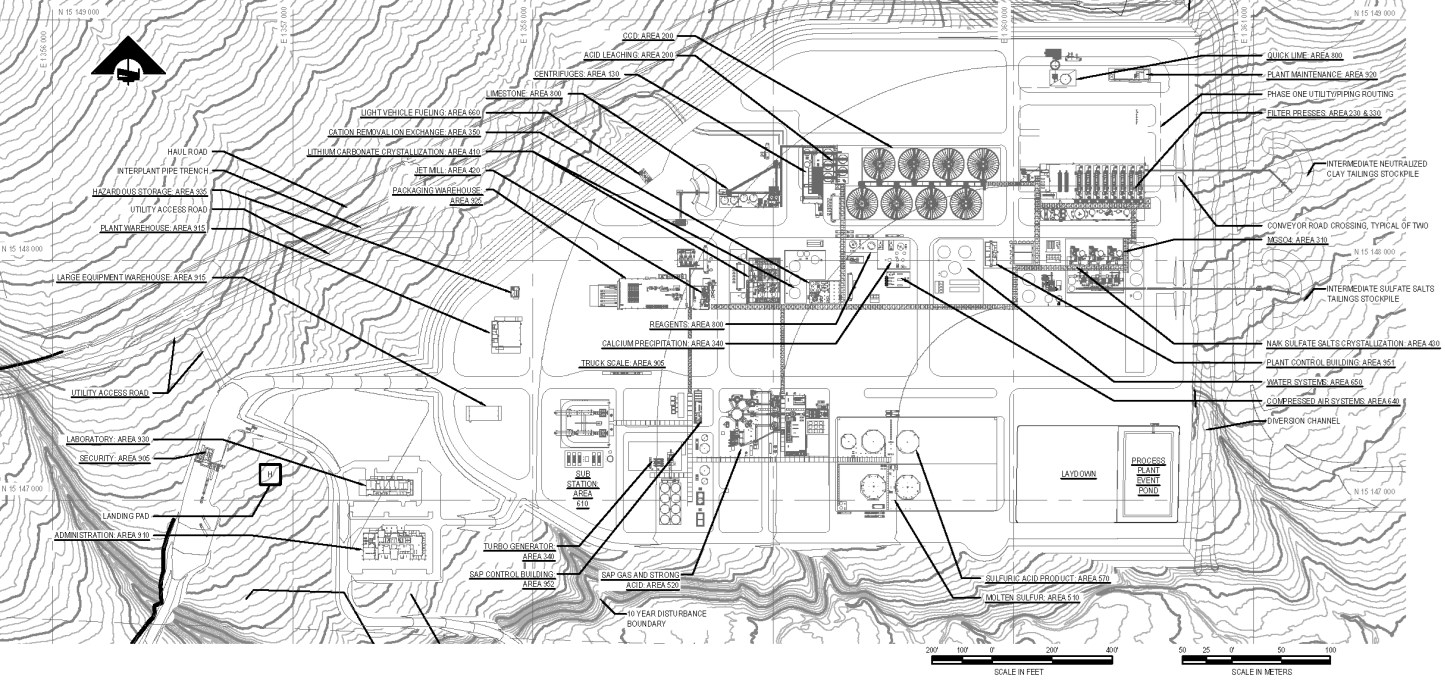

| Figure 18-2 | Process Facility General Arrangement (Phase 1 Only) | 192 |

| Figure 18-3 | Site Entrances | 193 |

| Figure 18-4 | Route Junction Satellite View | 194 |

| Figure 18-5 | Thacker Pass Water Supply System | 204 |

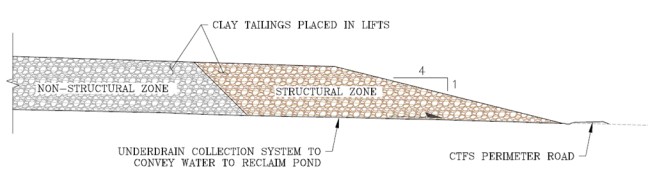

| Figure 18-6 | CTFS Conceptual Design | 207 |

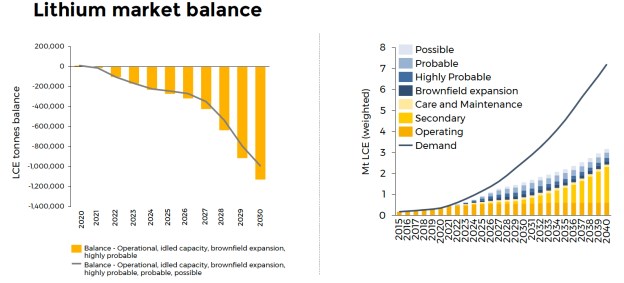

| Figure 19-1 | Lithium market balance 2020-2040 | 209 |

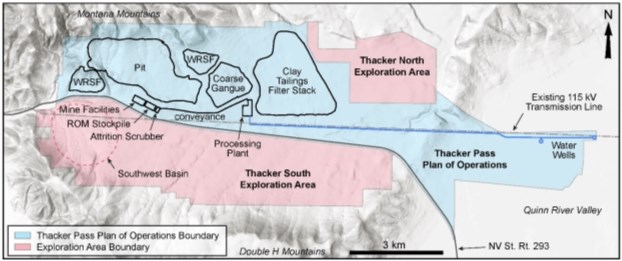

| Figure 20-1 | Plan of Operations and Exploration Area Permitted Boundaries | 212 |

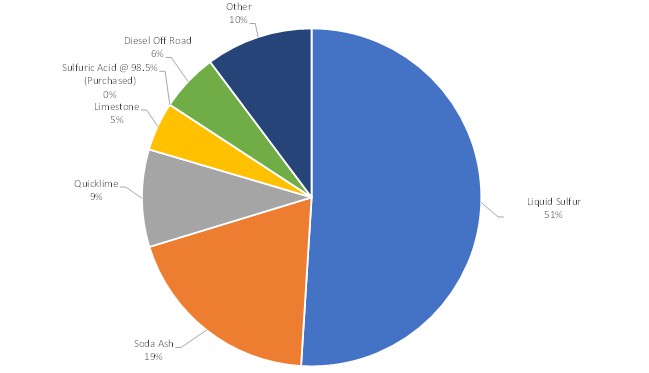

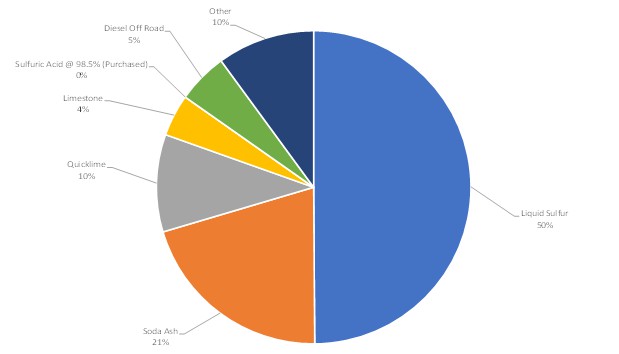

| Figure 21-1 | Raw Materials Cost (40-Year LOM - Base Case) | 251 |

| Figure 21-2 | Raw Materials Cost (Years 1-25 of 40-Year LOM) | 252 |

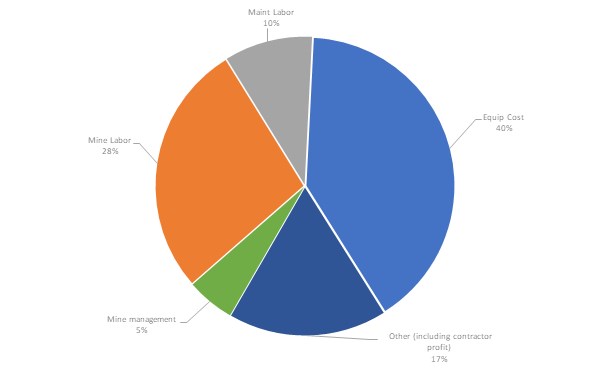

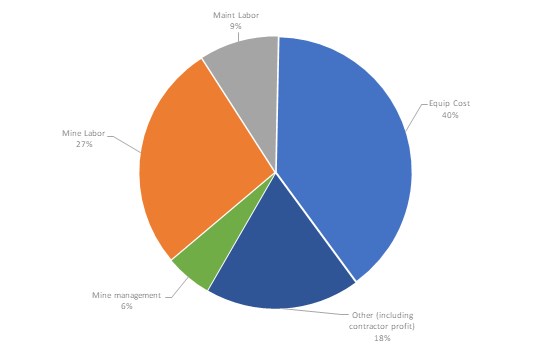

| Figure 21-3 | Distribution of mining and tailings management Operational Cost (40-Year LOM - Base Case) | 257 |

| Figure 21-4 | Distribution of mining and tailings management Operational Cost (Years 1-25 of 40-Year LOM Case) | 257 |

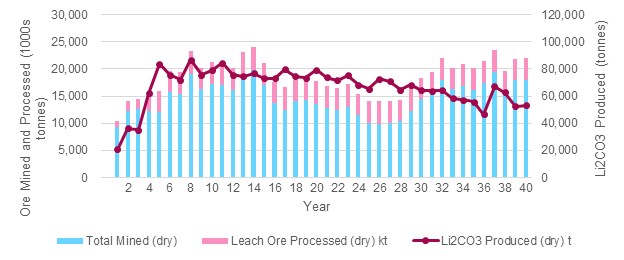

| Figure 22-1 | Total Mined, Ore Processed and Lithium Carbonate Production by Year | 267 |

| Figure 22-2 | Total Annual Revenue by Year | 268 |

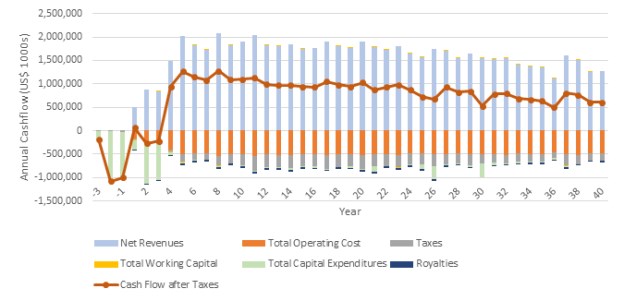

| Figure 22-3 | Undiscounted Annual Cash Flow | 270 |

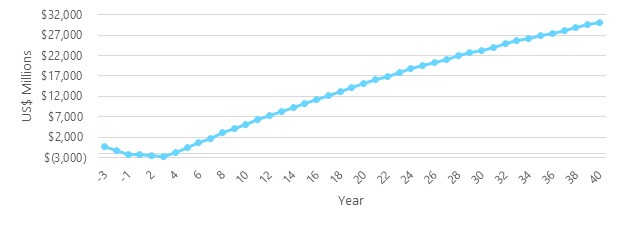

| Figure 22-4 | Cumulative Discounted Cash Flow | 270 |

| Figure 22-5 | Sensitivity Analysis of Various Variables, After-Tax NPV, 8% Discount Rate | 273 |

| Figure 22-6 | Sensitivity Analysis of Various Variables, After-Tax IRR, 8% Discount Rate | 274 |

| Figure 24-1 | Limestone Quarry pit outline | 282 |

| Figure 24-2 | Limestone Quarry cross section A-A' | 283 |

| Figure 24-3 | Transload Facility Site General Arrangement | 287 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

List of Tables

| Table 1-1 | LAC Drill Holes Provided in Current Database for the Thacker Pass Deposit | 3 |

| Table 1-2 | Mineral Resources Estimate as of November 2, 2022 | 5 |

| Table 1-3 | Mineral Reserves Estimate as of November 02, 2022 | 6 |

| Table 1-4 | Development Capital Cost Estimate Summary | 10 |

| Table 1-5 | 40-Year LOM Sustaining Capital Estimate Summary (Base Case) | 11 |

| Table 1-6 | First 25 Years of 40-Year LOM Sustaining Capital Estimate Summary | 11 |

| Table 1-7 | Operating Cost Estimate Summary (40-Year LOM - Base Case) | 11 |

| Table 1-8 | Operating Cost Estimate Summary (Years 1-25 of 40-Year LOM Case) | 12 |

| Table 1-9 | Production Scenario (40-Year LOM - Base Case) | 12 |

| Table 1-10 | Production Scenario - (Years 1-25 of 40-Year LOM Case) | 12 |

| Table 1-11 | Economic Evaluation - Lithium Carbonate Plant (40 Year LOM - Base Case) | 13 |

| Table 1-12 | Economic Evaluation - Lithium Carbonate Plant (Years 1-25 of 40-Year LOM Case) | 13 |

| Table 2-1 | List of Qualified Persons, Professional Designations and Site Visit Dates | 16 |

| Table 2-2 | Qualified Person Areas of Responsibility | 17 |

| Table 2-3 | Previously Filed Technical Reports | 18 |

| Table 2-4 | Abbreviations and Acronyms | 21 |

| Table 4-1 | Thacker Pass Project UM Claims Owned by LAC | 30 |

| Table 5-1 | Annual Precipitation at the Thacker Pass Project Site (in cm) | 37 |

| Table 7-1 | Chemical Analyses of Thacker Pass Smectite and Illite Clay Concentrates | 48 |

| Table 10-1 | LAC Drill Holes Provided in Current Database for the Thacker Pass Deposit | 54 |

| Table 11-1 | Bulk Density Sampling Program Summary by Lithology | 64 |

| Table 11-2 | Average Density Values | 66 |

| Table 12-1 | Drill Hole Survey Verification | 77 |

| Table 13-1 | Corresponding hole locations, depths and bulk bags collected | 83 |

| Table 13-2 | Bulk bags used for metallurgical testing | 85 |

| Table 13-3 | Samples for Variability Study | 88 |

| Table 13-4 | Summary of materials characterization testing (FLSmidth) | 89 |

| Table 13-5 | Attrition Scrubbing Test by LAC | 90 |

| Table 13-6 | Li and mass distribution of 50/50 clay slurry blend post attrition scrubbing, "intense" vs "mild + intense" | 91 |

| Table 13-7 | Process design criteria for classification, 75µm separation size, 70/30 illite/smectite blend | 91 |

| Table 13-8 | Solid-Liquid Separation test results 50/50 illite/smectite blend | 94 |

| Table 13-9 | Campaign 1 to 3 Material Balance Results | 99 |

| Table 13-10 | Campaign 4 Material Balance Results | 100 |

| Table 13-11 | Lithium leach % extraction of illite and smectite vs sulfuric acid dose | 101 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| Table 13-12 | Lithium extractions for various acid dose scenarios | 102 |

| Table 13-13 | Lithium leach extractions of various 70/30 illite/smectite blends | 103 |

| Table 13-14 | Limestone purity analysis of local grab samples | 105 |

| Table 13-15 | CaCO3 consumption to achieve pH 35 in neutralization slurry | 106 |

| Table 13-16 | Data for neutralization batches using CaCO3 and Mg Precipitation solids | 108 |

| Table 13-17 | SNF Maximum Thickener Underflow Operating Density | 109 |

| Table 13-18 | Variability Study Leach Parameters | 114 |

| Table 13-19 | Specific Gravity Ranges | 116 |

| Table 14-1 | Drill Holes Used in the Grade Estimation Model | 118 |

| Table 14-2 | Native Samples Statistics | 123 |

| Table 14-3 | Block Model Origin | 124 |

| Table 14-4 | Composite Samples Statistics | 124 |

| Table 14-5 | Variogram Summary | 128 |

| Table 14-6 | Average Density Values Used in the Resource Model | 133 |

| Table 14-7 | Cutoff Grade Inputs | 138 |

| Table 14-8 | Pit Optimizer Parameters | 138 |

| Table 14-9 | Resource Classification | 142 |

| Table 14-10 | Mineral Resources Estimate as of November 2, 2022 | 145 |

| Table 15-1 | Pit Optimizer Parameters | 146 |

| Table 15-2 | Lithium Losses | 150 |

| Table 15-3 | Mineral Reserves Estimate as of November 02, 2022 | 151 |

| Table 16-1 | Pit Geometry | 152 |

| Table 16-2 | Waste Material | 162 |

| Table 16-3 | Mine Quantities Summary (tonnes in millions unless noted) | 163 |

| Table 16-4 | 5-Year Average Mine Quantities Summary (tonnes in millions unless noted) (Continued) | 164 |

| Table 16-5 | Major Equipment Specifications | 165 |

| Table 16-6 | Support Equipment | 165 |

| Table 16-7 | Scheduled Hours by Fleet | 166 |

| Table 16-8 | Personnel List | 166 |

| Table 17-1 | Process Design Criteria - Beneficiation through Neutralized Tailing | 172 |

| Table 17-2 | Process Design Criteria - Purification Plant | 173 |

| Table 17-3 | Major Process Equipment - Beneficiation/Classification/Filtering | 174 |

| Table 17-4 | Major Process Equipment - Purification Process | 175 |

| Table 17-5 | Reagent Consumption (40-Year LOM - Base Case) | 184 |

| Table 17-6 | Reagent Consumption (First 25 Years of 40-Year Case) | 184 |

| Table 17-7 | Plant Water Use | 185 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| Table 17-8 | Steam Use | 185 |

| Table 17-9 | Power Demand by Area (based on Equipment List for DFS Load Study (Rev N, supplied by ITAC) | 186 |

| Table 17-10 | Metallurgical Accounting Sampler Summary, Major Process Inlets/Outlets | 188 |

| Table 17-11 | Process Control Sampler Summary | 188 |

| Table 18-1 | Life of Mine Primary Raw Material Logistics Scheme | 195 |

| Table 18-2 | System Voltages | 198 |

| Table 18-3 | Motor Voltages | 198 |

| Table 18-4 | Electrical Load Breakdown | 199 |

| Table 18-5 | Electrical Load Generation vs Import | 199 |

| Table 18-6 | Project Power Demands | 200 |

| Table 18-7 | Design and Requirement Volumes for Stockpiles and Facilities (Millions of Cubic Yards) | 205 |

| Table 19-1 | Lithium Price Forecast (Q3 2022) | 210 |

| Table 20-1 | Key Community Engagement Summary | 217 |

| Table 20-2 | Summary of Background Groundwater Profile 1 Exceedances | 224 |

| Table 21-1 | Development Capital Cost Estimate Summary | 234 |

| Table 21-2 | Sustaining Capital Estimate Summary (40-Year LOM - Base Case) | 234 |

| Table 21-3 | First 25 Years of 40-Year LOM Sustaining Capital Estimate Summary | 235 |

| Table 21-4 | Capital Cost Spend Schedule | 236 |

| Table 21-5 | Capital Cost Summary by Phase and Area | 237 |

| Table 21-6 | Work Breakdown Structure and Associated Responsibilities | 238 |

| Table 21-7 | Composite Trade Labor Rates | 240 |

| Table 21-8 | Owner's Cost Summary | 243 |

| Table 21-9 | Summary of Sustaining Capital Costs for Mine, Plant, and Sulfuric Acid Plant ($M) | 245 |

| Table 21-10 | CTFS and CGS Expansion Area and Costs | 246 |

| Table 21-11 | Reclamation Costs | 246 |

| Table 21-12 | Lithium Americas Labor Requirements and Average Annual Cost Summary (40-Year Base Case) | 248 |

| Table 21-13 | Raw Material Purchase and Delivered Pricing | 249 |

| Table 21-14 | Raw Material Annual Consumption (40-Year LOM Base Case) | 250 |

| Table 21-15 | Raw Material Annual Consumption (Years 1-25 of 40 Year LOM) | 250 |

| Table 21-16 | Average Annual Power Cost (40 Year LOM - Base Case) | 252 |

| Table 21-17 | Average Annual Power Cost (Years 1 to 25 of 40 Year LOM) | 252 |

| Table 21-18 | Factored Maintenance Annual Allowances | 253 |

| Table 21-19 | General and Administrative Costs (40 Year LOM - Base Case) | 253 |

| Table 21-20 | General and Administrative Costs (Years 1 to 25 of 40 Year LOM) | 254 |

| Table 21-21 | Mining and Clay Tailings Operating Cost Estimate (40-Year LOM Base Case) | 256 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| Table 21-22 | Mining and Clay Tailings Operating Cost Estimate (Years 1-25 of 40 Year LOM) | 256 |

| Table 21-23 | Battery Limits for Mining Contractor Operating Cost Estimate | 258 |

| Table 21-24 | Clay and Salt Tailings Battery Limits | 258 |

| Table 21-25 | Mining Estimation Methodology | 259 |

| Table 21-26 | Average Lithium Process Operating Costs (40 Year LOM - Base Case) | 259 |

| Table 21-27 | Average Lithium Process Operating Costs (Years 1-25 of 40 Year LOM) | 260 |

| Table 21-28 | Average Sulfuric Acid Plant Operating Costs (40 Year LOM - Base Case) | 260 |

| Table 21-29 | Average Sulfuric Acid Plant Operating Costs (Years 1-25 of 40 Year LOM) | 260 |

| Table 21-30 | Project Operating Cost Summary (Years 1-40 Life of Mine - Base Case) | 261 |

| Table 21-31 | Project Operating Cost Summary (Years 1-25 of 40 Year LOM) | 261 |

| Table 22-1 | Initial Capital Costs Summary | 265 |

| Table 22-2 | Sustaining Capital Summary | 266 |

| Table 22-3 | Operating Costs Summary (40-Year LOM - Base Case) | 266 |

| Table 22-4 | Operating Costs Summary (Years 1-25 of 40 Year LOM) | 266 |

| Table 22-5 | Average Production Values (40 Year/Base Case) | 267 |

| Table 22-6 | Average Production Values (Years 1-25 of 40-Year LOM) | 267 |

| Table 22-7 | Total Annual Production and Revenue (40 Year LOM - Base Case) | 268 |

| Table 22-8 | Total Annual Production and Revenue (Years 1-25 of 40 Year LOM) | 268 |

| Table 22-9 | After-Tax Financial Model Results (40 Year LOM - Base Case) | 271 |

| Table 22-10 | After-Tax Financial Model Results (Years 1-25 of 40 Year LOM) | 271 |

| Table 22-11 | Financial Model | 272 |

| Table 22-12 | After-Tax NPV at 8% ($ Millions) and IRR | 274 |

| Table 22-13 | NPV for Various Discount Rates (40-Year LOM) | 275 |

| Table 24-1 | Overview Schedule | 279 |

| Table 24-2 | Delivered Limestone tonnes (LS) | 280 |

| Table 24-3 | Delivered and ROM tonnes | 281 |

| Table 24-4 | Pit shell material quantities and quality | 283 |

| Table 24-5 | Limestone Delivery Cost per tonne | 284 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

1 Summary

1.1 Introduction

Lithium Nevada Corp. (LNC), a wholly owned subsidiary of Lithium Americas Corp. (LAC), is advancing the Thacker Pass Project (hereafter referred to as "the Project"), which was formerly known as the Lithium Nevada Project or Stage I of the Kings Valley Lithium Project. The Project is 100% owned by LNC. The terms "LNC" and "LAC" are used throughout the report to denote the owner of the Project.

The Project encompasses the mineral claims that were formerly referred to as the Stage I area of the Kings Valley Lithium Project and includes lithium (Li) claystone mining at the Thacker Pass Deposit. This Technical Report presents the results of a Feasibility Study evaluation of the Project.

M3 Engineering & Technology Corporation (M3) was commissioned by LAC to prepare this Technical Report. In preparing this Report, M3 has relied upon input from LAC and information prepared by a number of qualified independent consulting groups particularly regarding regional geology, geological mapping, exploration, and resource estimation. See Section 2 for a full discussion of contributors to this study.

The economic analysis is based on Q3 2022 pricing for capital and operating costs.

1.2 Property Location, Description and Ownership

The Project is located in Humboldt County in northern Nevada, approximately 100 kilometers (km) north-northwest of Winnemucca, approximately 33 km west-northwest of Orovada, Nevada, and 33 km due south of the Oregon border. It is situated within 44 North (T44N), Range 34 East (R34E), and within portions of Sections 1 and 12; T44N, R35E within portions of Sections 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, and 17; and T44N, R36E, within portions of Sections 7, 8, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, and 29, and encompasses approximately 4,236 hectares (ha).

Section 6 of this Technical Report further describes the history of the Project, and Section 1.1 also describes ownership in brief.

1.3 Geology

The Project is located within an extinct 40x30 km supervolcano named McDermitt Caldera, which was formed approximately 16.3 million years ago (Ma) as part of a hotspot currently underneath the Yellowstone Plateau. Following an initial eruption and concurrent collapse of the McDermitt Caldera, a large lake formed in the caldera basin. This lake water was extremely enriched in lithium and resulted in the accumulation of lithium-rich clays.

Late volcanic activity uplifted the caldera, draining the lake and bringing the lithium-rich moat sediments to the surface resulting in the near-surface lithium deposit which is the subject of the Project.

The Thacker Pass Deposit sits sub-horizontally beneath a thin alluvial cover and is partially exposed at the surface. The sedimentary section consists of alternating layers of claystone and volcanic ash. Basaltic lavas occur intermittently within the sedimentary sequence. The moat sedimentary section at the Project site overlies the indurated intra-caldera Tuff of Long Ridge. A zone of silicified sedimentary rock, the Hot Pond Zone (HPZ), occurs at the base of the sedimentary section above the Tuff of Long Ridge.

Clay in the Thacker Pass Deposit includes two distinct types of clay mineral, smectite and illite. Smectite clay occurs at relatively shallow depths in the deposit and contain roughly 2,000 - 4,000 parts per million (ppm) lithium. Higher lithium contents (commonly 4,000 ppm lithium or greater) are typical for illite clay which occurs at relatively moderate to deep depths and contain values approaching 9,000 ppm lithium in terms of whole-rock assay.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

1.4 Deposit Types

Lithium enrichment (>1,000 ppm) in the Thacker Pass Deposit and deposits of the Montana Mountains occur throughout the caldera lake sedimentary sequence above the intra-caldera Tuff of Long Ridge. The exact cause for the lithium enrichment in the caldera lake sediments is still up for debate. The presence of sedimentary carbonate minerals and magnesium-smectite (hectorite) throughout the lake indicates that the clays formed in a basic, alkaline, closed hydrologic system.

It is likely that two primary mechanisms play a role in the genesis of the deposit: (1) neoformation of smectite in a closed lake, rich in lithium due to the leaching of nearby and underlying volcanic glass (Benson et al., 2017b); and (2) alteration of a portion of the smectite-bearing clays to illite during intracaldera hydrothermal alteration associated with the uplift of the Montana Mountains.

Caldera lake sediments of the McDermitt Caldera contain elevated lithium concentrations compared to other sedimentary basins. Exploration results support the proposed model and have advanced the understanding of the geology of the Thacker Pass Deposit.

1.5 Exploration

Exploration programs have been carried out in the McDermitt Caldera since 1975, including the drilling campaigns identified in Section 1.6. A collar survey was completed by LAC for the 2007-2008 drilling program using a Trimble GPS (Global Positioning System). The topographic surface of the Project area was mapped by aerial photography dated July 6, 2010, by MXS, Inc. for LAC using Trimble equipment for ground control. In addition to drilling in 2017, LAC conducted five seismic survey lines along a series of historical drill holes to test the survey method's accuracy and resolution in identifying clay interfaces.

1.6 Drilling

The Thacker Pass Deposit area has been explored for minerals since the 1970s by different companies and drilling campaigns. Table 1-1 categorizes the different drilling campaigns, number of holes drilled, and type of drilling utilized. Drilling methods were compared to test for sample bias, using core drilling as the standard. Rotary, sonic, and reverse circulation drilling all showed slight sample biases when compared to core drilling. Only HQ core holes were used for resource modeling to minimize the chance of sample bias. The drilling techniques, core recovery, and sample collection procedures provided results that are suitable for use in resource estimation. There are no drilling, sample, or recovery factors that materially impact the accuracy and reliability of results. The data is adequate for use in resource estimation.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table 1-1 LAC Drill Holes Provided in Current Database for the Thacker Pass Deposit

|

Drilling |

Number |

Type |

Hole IDs in Database |

Number used in |

|

Chevron |

24 |

Rotary |

PC-84-001 through PC-84-012, PC-84-015 through PC-84-026 |

0 |

|

1 |

Core |

PC-84-014c |

0 |

|

|

LAC 2007-2010 |

230 |

HQ Core |

WLC-001 through WLC-037, WLC-040 through WLC-232 |

227 |

|

7 |

PQ Core |

WPQ-001 through WPQ-007 |

0 |

|

|

5 |

HQ Core |

Li-001 through Li-005 |

0 |

|

|

8 |

RC |

TP-001 through TP-008 |

0 |

|

|

2 |

Sonic |

WSH-001 through WSH-002 |

0 |

|

|

LAC 2017-2018 |

144 |

HQ Core |

LNC-001 through LNC-144 |

139 |

Notes: Holes WLC-040, WLC-076, WLC-183, LNC-002, LNC-012, LNC-081, LNC-083, and LNC-110 were not used in the Resource Estimate due to proximity to other core holes.

1.7 Sample Preparation, Analyses and Security

The drilled core was securely placed in core boxes and labelled at site. The boxes of drilled core were then transported to the secure LAC logging and sampling facility in Orovada, Nevada, where they were lithologically logged, photographed, cut, and sampled by LAC employees and contractors. The samples were either picked up by ALS Global (ALS) by truck or delivered to ALS in Reno, Nevada by LAC employees.

Once at ALS, the samples were dried at a maximum temperature of 60ºC. The entire sample was then crushed with a jaw crusher to 90% passing a 10-mesh screen. LAC used ALS Global's standard ME-MS61 analytical package for all of the samples collected which provides analytical results for 48 elements, including lithium. Certified analytical results were reported on the ICP-MS determinations.

Blank samples were used to check for cross-contamination between samples at the lab. Standard samples consisting of a high grade and a low grade lithium bearing claystone from the Project area were used to test the accuracy and precision of the analytical methods used at the lab. Duplicate samples are used to check the precision of the analytical methods of the lab and were taken every 30.5 m of core (i.e., they were collected downhole every 100 feet (ft)).

1.8 Data Verification

1.8.1 Mineral Resources

Certified laboratory certificates of assays were provided in pdf (Adobe Acrobat Portable Document Format) as well as comma separated value (csv) formatted files for verification of the sample assays database. Sample names, certificate identifications, and run identifications were cross referenced with the laboratory certificates and sample assay datasheet for spot checking and verification of data. No data anomalies were discovered during this check.

Quality Assurance / Quality Control (QA/QC) methodology utilized by LAC and results of these checks were discussed between LAC geologists and the QP.

Geologic logs, Access databases, and Excel spreadsheets were provided to the QP for cross validation with the Excel lithological description file. Spot checks between Excel lithological description sheets were performed against the source data with no inconsistencies found with the geologic unit descriptions.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Verification of the block model was performed by the creation of a geostatistical model and the review of its various outputs. Histograms, HERCO grade tonnage curves, and swath plots were created and analyzed to validate the accuracy of the block model.

Based on the various reviews, validation exercises and remedies outlined above, the QP concluded that the data is adequate for use for resource estimation.

1.8.2 Mineral Reserves

The Mineral Reserves QP reviewed the following as part of the mine planning, cost model and Mineral Reserves data verification.

1.9 Metallurgical Testing

Extensive metallurgical and process development testing has been performed both internally at LAC's Process Testing Center (PTC) and externally with vendors and contract commercial research organizations. Data collected from test programs has been used for flowsheet development, various equipment selection, definition of operating parameters and development of process design criteria. The most relevant metallurgical test data are discussed in Section 13.

The ore samples used for all metallurgical testing were collected from the proposed pit at the Thacker Pass Deposit. The samples spatially represent the ore body, with material collected from both undisturbed upper smectite horizons and uplifted faulted blocks that represent deeper illite horizons.

Conclusions of test work from the key areas are listed below:

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Refinement and further optimization to the process continue to be made as required.

1.10 Mineral Resources and Reserves

1.10.1 Mineral Resources

The Mineral Resources estimate for the Thacker Pass Deposit is summarized in Table 1-2. Mineral Resources have been classified per the CIM 2014 Definition Standards and estimated using the 2019 CIM Best Practice Guidelines. This resource estimate uses a cutoff grade of 1,047 ppm lithium.

Table 1-2 Mineral Resources Estimate as of November 2, 2022

|

Category |

Tonnage |

Average Li |

Lithium Carbonate |

|

Measured |

534.7 |

2,450 |

7.0 |

|

Indicated |

922.5 |

1,850 |

9.1 |

|

Measured & Indicated |

1,457.2 |

2,070 |

16.1 |

|

Inferred |

297.2 |

1,870 |

3.0 |

Notes:

1. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

2. Mineral Resources are inclusive of 217.3 million metric tonnes (Mt) of Mineral Reserves.

3. Mineral Resources are reported using an economic break-even formula: "Operating Cost per Resource Tonne"/"Price per Recovered Tonne Lithium" * 10^6 = ppm Li Cutoff. "Operating Cost per Resource Tonne" = US$88.50, "Price per Recovered Tonne Lithium" is estimated: ("Lithium Carbonate Equivalent (LCE) Price" * 5.323 *(1 - "Royalties") * "Recovery". Variables are "LCE Price" = US$22,000/tonne Li2CO3, "Royalties" = 1.75% and "Recovery" = 73.5%.

4. Presented at a cutoff grade of 1,047 ppm Li.

5. A resource economical pit shell has been derived from performing a pit optimization estimation using Vulcan software.

6. The conversion factor for lithium to LCE is 5.323.

7. Applied density for the mineralization is 1.79 t/m3(Section 11.4)

8. Measured Mineral Resources are in blocks estimated using at least six drill holes and eighteen samples within a 262 m search radius in the horizontal plane and 5 m in the vertical direction; Indicated Mineral Resources are in blocks estimated using at least two drill holes and six to eighteen samples within a 483 m search radius in the horizontal plane and 5 m in the vertical direction; and Inferred Mineral Resources are blocks estimated with at least two drill holes and three to six samples within a search radius of 722 m in the horizontal plane and 5 m in the vertical plane.

9. Tonnages and grades have been rounded to accuracy levels deemed appropriate by the QP. Summation errors due to rounding may exist.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

1.10.2 Mineral Reserves

The Mineral Reserves estimate for the Thacker Pass Deposit are based on an approved permitted pit shell developed in 2019 for the EIS. The Mineral Reserves are a modified subset of the Measured and Indicated Mineral Resources. A cutoff grade variable of kg of lithium extracted per run-of-mine (ROM) tonne was used to develop the Mineral Reserves for a 40-year mine plan producing a total life of mine (LOM) plant leach ore feed of 154.2 million dry tonnes. The leach ore feed is the ROM ore dry less the ash dry tonnes. The cutoff grade variable, kilograms of lithium extracted per tonne of ROM feed, is estimated using formulas and variables developed by LAC and is applied to each individual block of the geologic block model. The cutoff grade estimation is 1.533 kg of lithium recovered per tonne of ROM feed.

Overall reserve ore and waste tonnages are modeled using Maptek's geologic software package.

Waste consists of various types of material, including basalt, volcanic ash, alluvium and clay that does not meet the ore definition or the cutoff grade described above.

The classified Mineral Reserves are summarized in Table 1-3 for the 40-year permitted pit. This estimate uses a maximum ash percent cutoff of 85% and a cutoff grade of 1.533 kg of lithium extracted per tonne of ROM feed. Additionally, a 95% mining recovery factor is applied. A dilution percentage was not applied.

Table 1-3 Mineral Reserves Estimate as of November 02, 2022

|

Category |

Tonnage |

Average Li |

Lithium Carbonate |

|

Proven |

192.9 |

3,180 |

3.3 |

|

Probable |

24.4 |

3,010 |

0.4 |

|

Proven and Probable |

217.3 |

3,160 |

3.7 |

Note:

1. Mineral Reserves have been converted from measured and indicated Mineral Resources within the feasibility study and have demonstrated economic viability.

2. Reserves presented at an 85% maximum ash content and a cut-off grade of 1.533 kg of lithium extracted per tonne run of mine feed. A sales price of $5,400 US$/t of Li2CO3 was utilized in the pit optimization resulting in the generation of the reserve pit shell in 2019. Overall slope of 27 degrees was applied. For bedrock material pit slope was set at 47 degrees. Mining and processing cost of $57.80 per tonne of ROM feed, a processing recovery factor of 84%, and royalty cost of 1.75% were addition inputs into the pit optimization.

3. A LOM plan was developed based on equipment selection, equipment rates, labor rates, and plant feed and reagent parameters. All Mineral Reserves are within the LOM plan. The LOM plan is the basis for the economic assessment within the Technical Report, which is used to show economic viability of the Mineral Reserves.

4. Applied density for the ore is 1.79 t/m3 (Section 11.4).

5. Lithium Carbonate Equivalent is based on in-situ LCE tonnes with 95% recovery factor.

6. Tonnages and grades have been rounded to accuracy levels deemed appropriate by the QP. Summation errors due to rounding may exist.

7. The reference point at which the Mineral Reserves are defined is at the point where the ore is delivered to the run-of-mine feeder.

1.11 Mine Methods

The mining method chosen will use hydraulic excavators loading a fleet of end dump trucks. The fleet will be used for all material excavation and haulage. The material hauled includes ore, waste, and attrition scrubber reject waste. The attrition scrubber waste is oversized material removed after the ore is mixed with water.

Mining and material handling will be contracted through Sawtooth, a subsidiary of North American Coal Corporation (NAC). A mine plan has been developed to maximize recovered lithium carbonate over the life of mine.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

The mine design and mine plan are based on the approved EIS permit pit shell. The truck and excavation fleet will develop several offset benches to maintain a geotechnically stable highwall slope. The bench heights are designed to enable the mine to have multiple grades of ore exposed at any given time, allowing flexibility to deliver different types and grades of ore to be blended as needed and to maintain an illite to smectite ratio feed rate in the 30:70 to 70:30 range.

The annual production rate is based on varying ore feed rates determined by the availability of sulfuric acid for the leaching process. Phase 1 (years 1-3) has an annual ore leach feed rate of 1.7 million dry tonnes and Phase 2 (years 4 to 40) has an annual leach ore feed rate of 4.0 million dry tonnes. The following is a summary of the Life-of-Mine production:

In the first five years, the mine waste will primarily be hauled to the out-of-pit waste storage area. After five years, the mine waste will primarily be dumped back into the empty pit. Mine waste will also be used for construction fill material. Ore will be hauled to a run-of-mine stockpile located to the south of the pit. The attrition scrubber reject material will be hauled to the out-of-pit waste stockpile or back into the empty pit.

1.12 Recovery Methods

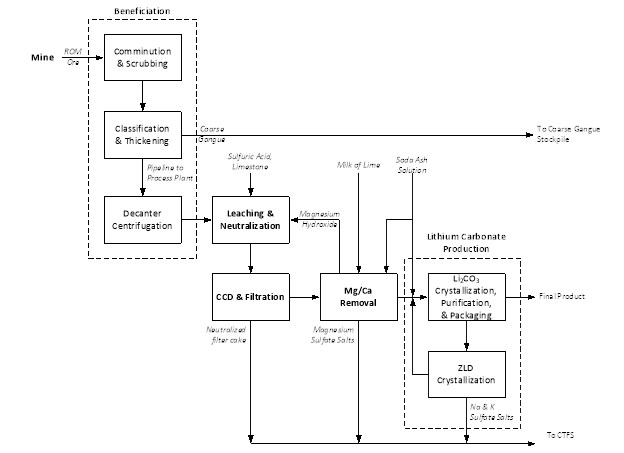

The current flow sheet, material balance, and process design criteria (PDC) for the Project have been developed from metallurgical test work and a steady-state process model built in Aspen® Plus software. Design criteria, major equipment, reagent and utility consumptions, and overall recovery estimates used for lithium carbonate production forecasts provide the basis for the Project economic model. The process flow sheet consists of five key areas: beneficiation, leaching and neutralization, CCD and filtration circuit, magnesium and calcium removal (i.e., purification) and lithium carbonate production. In beneficiation, the lithium concentration of ore is on average, upgraded from approximately 3,153 ppm to approximately 4,438 ppm. Lithium is then leached from process slurry by sulfuric acid (H2SO4), with an average leach extraction of approximately 86.2% over the life-of-mine.

Major waste products include coarse gangue from beneficiation, neutralized leach residue filter cake, magnesium sulfate salts, and sodium/potassium sulfate salts. The filter cake and salts will be conveyed to a clay tailings filter stack facility which will be progressively reclaimed during the life of the Project. On average, nearly 19,000 tonnes per day (t/d) of cake and salts will be generated. Coarse gangue is generated at an average rate of 4,400 t/d.

There are five major areas contributing to lithium losses in the process plant:

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Recovery of lithium during operations will fluctuate with varying ore mineralization and ore chemistry.

1.13 Infrastructure

The mining and Processing Plant operations are located within the McDermitt Caldera in northwest Nevada. Raw water is sourced via aquifer-fed wells seven miles east of the processing plant. The layout contemplates a total of two new entrances and utilizing one existing entrance from SR-293 onto the Project site. See the overall site general arrangement in Figure 1-1. The Project is planned to be constructed in two phases. To support lithium carbonate production as discussed in Section 17, Phase 1 will consist of a single sulfuric acid plant with a nominal production rate of 3,000 tonnes per day sulfuric acid. Phase 2 will begin three years later with the addition of a second sulfuric acid plant with an additional nominal production rate of 3,000 t/d.

Figure 1-1 Overall Site General Arrangement

Source: M3, 2022

1.13.1 Raw Materials

Raw materials for the Project are to be delivered to the site by over highway trucks during Phase 1 and Phase 2. Approximately 108 trucks per day will make raw material deliveries to the site. A local rail-to-truck transloading facility located in Winnemucca will allow for transfer of most raw materials for delivery to the Project site.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

1.13.2 Sulfuric Acid Plant

Phase 1 and Phase 2 will each have a single sulfuric acid plant capable of producing a nominal 3,000 t/d (100 weight % H2SO4 basis) of sulfuric acid by the double contact, double absorption process. Liquid sulfur is delivered to site by truck and is unloaded into storage tanks. The sulfuric acid generated is stored and then used in the process plant. The acid plant will also generate power. Additional power will be purchased and delivered to site.

1.13.3 Clay Tailings Filter Stack (CTFS)

At full plant production, up to approximately 20,300 dry t/d of clay tailings and salts will be generated over a 40-year period, resulting in a total quantity of 272 million dry tonnes (328 million cubic yards or 250.7 million cubic meters (Mm3)) requiring secure disposal. The Clay Tailings Filter Stack (CTFS) is designed for a total quantity of 290.5 million dry tonnes (a volume of 350.4 million cubic yards or 267.9 Mm3) and can be expanded as needed to store material needing containment.

1.13.4 Power

Demand loads for Phase 1 and Phase 2 are 75.4 megawatts (MW) and 66.4 MW respectively, for a combined total of 141.8 MW demand during Phase 2. Power will be generated at the sulfuric acid plant from the steam generated from excess heat along with a maximum anticipated import load of 51.9 MW (455 gigawatt hours per year (GWh/year)). Thacker Pass is located in the service territory of Harney Electric Cooperative (HEC). A 115 kilovolt (kV) line passes through the site. Since the Nevada power market is regulated, LAC will purchase all imported power from HEC. HEC infrastructure to support this import load will need to be improved. HEC has a full requirements long-term contract to purchase 100% power from Bonneville Power Administration (BPA) through NV Energy. BPA has power available to sell, but constraints on existing transmission infrastructure to deliver the power to the HEC system are still being studied by NV Energy.

1.13.5 Water

Phase 1 and Phase 2 water demand is approximately 3.5 Mm3 (2,850 acre-ft) per year and 7.0 Mm3 (5,700 acre-ft) per year respectively. Water will be supplied from an existing well in the Quinn River Valley. Lithium Americas has a leasing agreement for Phase 1 water rights and is awaiting a hearing decision from the Nevada Division of Water Resources (NDWR) to transfer water rights to the water well location in 2023. Phase 2 water rights have been partially secured and plans to pursue other opportunities to acquire the remainder of the water requirements.

1.14 Market Studies and Contracts

Lithium demand displayed significant growth in 2021 and 2022 due to strong consumer demand for electric vehicles, with lithium carbonate pricing outpacing lithium hydroxide on the spot market. Contract pricing is expected to continue to significantly increase for battery-grade lithium chemicals with market demand balancing between lithium hydroxide and lithium carbonate towards the end of the decade. Near-term and mid-term pricing is expected to rise as demand outpaces supply with not enough lithium chemical production to ease market tightness. Long-term pricing for lithium chemicals is expected to be supported by unprecedented market demand combined with lack of supply as pressure from customers to incorporate carbon-neutral and sustainable technologies. These market conditions incentivize and support CAPEX-intensive greenfield projects.

The pricing forecast for lithium carbonate is based on the Wood Mackenzie third quarter 2022 lithium price outlook. Lithium carbonate pricing is set at $24,000 US$/t for each year for the financial model and the Resource Estimate was based on $22,000 US$/t lithium pricing.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

1.15 Capital and Operating Costs

The capital cost estimate for the Project has been prepared by M3, Industrial TurnAround Corporation (ITAC), LNC, and third-party contractors in accordance with the scope of the Project. The capital cost estimate covers post-sanction early works, mine development, mining, the process plant, the transload facility, commissioning and all associated infrastructure required to allow for successful construction and operations. Development capital costs are as shown in Table 1-4.

Table 1-4 Development Capital Cost Estimate Summary

|

Description |

Ph1 Costs (US$ M) |

Ph2 Costs (US$ M) |

Responsible |

|

Mine |

|

|

|

|

Equipment Capital (Contract Mining) |

0 |

0.0 |

Sawtooth |

|

Mine Development |

51.1 |

26.3 |

Sawtooth |

|

Contingency (13.1%) |

6.7 |

3.4 |

Sawtooth |

|

Total Mine |

57.8 |

29.7 |

|

|

Process Plant and Infrastructure |

|

|

|

|

Costs (Direct & Indirect) |

1,735.4 |

1,398.5 |

M3/ITAC/EXP |

|

Contingency |

227.3 |

183.2 |

EDG |

|

Total Process Plant & Infrastructure |

1,962.7 |

1,581.7 |

|

|

Offsite - Transload Facility |

|

|

|

|

Costs (Direct & Indirect) |

69.0 |

27.1 |

Owner/Savage |

|

Contingency |

9.0 |

3.5 |

Owner/EDG |

|

Total Offsite Transload facility |

78.1 |

30.6 |

|

|

Owner's Costs |

|

|

|

|

Costs |

149.8 |

75.6 |

Owner |

|

Contingency |

19.6 |

9.9 |

Owner/EDG |

|

Total Owner's Costs |

169.4 |

85.5 |

|

|

TOTAL DEVELOPMENT CAPITAL |

2,268.0 |

1,727.5 |

|

Table 1-5 shows life of mine sustaining capital costs for the base case. Table 1-6 shows sustaining capital for the first 25 years of the 40-year life of mine.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table 1-5 40-Year LOM Sustaining Capital Estimate Summary (Base Case)

|

Description |

*LOM Costs |

Responsible |

|

Mine |

|

|

|

Equipment Capital |

264.3 |

Sawtooth/M3 |

|

Mobile Equipment |

|

|

|

Equipment Capital |

26.6 |

Owner |

|

Process Plant and Infrastructure |

|

|

|

Process Plant |

822.9 |

Owner |

|

Sulfuric Acid Plant |

244.2 |

EXP |

|

CTFS and CGS |

149.0 |

Owner |

|

Offsite Transload Facility |

|

|

|

Transload Facility |

3.4 |

Owner |

|

TOTAL SUSTAINING CAPITAL |

$1,510.2 |

|

|

Contract Mining Capital Repayment |

$48.8 |

Sawtooth/M3 |

* Phase 2 capital costs are not included in sustaining costs

Table 1-6 First 25 Years of 40-Year LOM Sustaining Capital Estimate Summary

|

Description |

*LOM Costs (US$ M) |

Responsible |

|

Mine |

|

|

|

Equipment Capital |

180.0 |

Sawtooth/M3 |

|

Mobile Equipment |

|

|

|

Equipment Capital |

15.2 |

Owner |

|

Process Plant and Infrastructure |

|

|

|

Process Plant |

230.7 |

Owner |

|

Sulfuric Acid Plant |

104.8 |

EXP |

|

CTFS and CGS |

95.6 |

Owner |

|

Offsite Transload Facility |

|

|

|

Transload Facility |

2.1 |

Owner |

|

TOTAL SUSTAINING CAPITAL |

$628.4 |

|

|

Contract Mining Capital Repayment |

$48.8 |

Sawtooth/M3 |

* Phase 2 capital costs are not included in sustaining costs

Operating costs were developed by Sawtooth Mining, LAC, and M3. Annual operating costs are summarized by operating area: Mine, Lithium Process Plant, Sulfuric Acid Plant, and General & Administrative (G&A). Operating costs in each area include labor, maintenance materials and supplies, raw materials, outside services, among others. Average operating costs at $7,198/tonne of lithium carbonate produced, or $480.7 million per annum for all 40 years (or $6,743/tonne and $471.4 million the first 25 years). The process operating costs are based on Q1-Q4 2022 pricing. See Table 1-7 and Table 1-8.

Table 1-7 Operating Cost Estimate Summary (40-Year LOM - Base Case)

|

Area |

Annual Average |

$/tonne Product |

Percent of Total |

|

Mine |

76.4 |

1,144 |

16% |

|

Lithium Process Plant |

214.6 |

3,213 |

45% |

|

Liquid Sulfuric Acid Plant |

175.4 |

2,627 |

36% |

|

General & Administrative |

14.3 |

215 |

3% |

|

Total |

$480.7 |

7,198 |

100% |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table 1-8 Operating Cost Estimate Summary (Years 1-25 of 40-Year LOM Case)

|

Area |

Annual Average ($-M) |

$/tonne Product |

Percent of Total |

|

Mine |

71.7 |

1,026 |

15% |

|

Lithium Process Plant |

215.9 |

3,088 |

46% |

|

Liquid Sulfuric Acid Plant |

169.4 |

2,424 |

36% |

|

General & Administrative |

14.3 |

205 |

3% |

|

Total |

$471.4 |

6,743 |

100% |

1.16 Financial Model

An economic analysis was carried out using a discounted cash flow (DCF) model, which was prepared by LAC with input from M3, ITAC, and EXP U.S. Services Inc. (EXP). The final financial model used to generate numbers in this report was audited and managed by M3, with reliance on third party experts for individual components. Annual cash flow projections were estimated for forty years based on the life of mine plan, estimates of capital expenditures, production costs, taxes, royalties, and sales from lithium carbonate production. The only revenue stream is sales of lithium carbonate.

Any investments in the Project to date are not amortized in the model.

Production profiles outlined in this technical report are limited to the Company's Proven and Probable Mineral Reserves. The production and financial outcomes from these reserves are summarized in Table 1-9 to Table 1-12. A sensitivity analysis has shown the Project is more sensitive to the lithium price than it is to either CAPEX or OPEX.

Table 1-9 Production Scenario (40-Year LOM - Base Case)

|

Category |

Units |

Value |

|

Operational Life |

years |

40 |

|

Mine and Process Plant Operational Life |

years |

40 |

|

Ore Reserve Life |

years |

40 |

|

Average Annual EBITDA |

$-M / yr |

1,093.5 |

|

After-tax Net Present Value (NPV) @ 8% Discount Rate |

$-M |

5,726.9 |

|

After-tax Internal Rate of Return (IRR) |

% |

21.4% |

|

Payback (undiscounted) |

years |

5.4 |

|

Note: Includes capital investments in years up to production |

||

Table 1-10 Production Scenario - (Years 1-25 of 40-Year LOM Case)

|

Category |

Units |

Value |

|

Operational Life |

years |

25 |

|

Mine and Process Plant Operational Life |

years |

25 |

|

Ore Reserve Life |

years |

40 |

|

Average Annual EBITDA |

$-M / yr |

1,176.2 |

|

After-tax NPV @ 8% Discount Rate |

$-M |

4,950.1 |

|

After-tax IRR |

% |

21.2% |

|

Payback (undiscounted) |

years |

5.4 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table 1-11 Economic Evaluation - Lithium Carbonate Plant (40 Year LOM - Base Case)

|

Category |

Units |

Value |

|

Operational Life |

years |

40 |

|

Annual Lithium Carbonate Production |

k-tonnes |

66.8 |

|

Metallurgical Recovery |

% |

73.2% |

|

Ore Reserves Production Scenario |

years |

40 |

|

Annual LCE Mined |

k-tonnes |

91.3 |

Table 1-12 Economic Evaluation - Lithium Carbonate Plant (Years 1-25 of 40-Year LOM Case)

|

Category |

Units |

Value |

|

Operational Life |

years |

25 |

|

Annual Lithium Carbonate Production |

k-tonnes |

69.9 |

|

Metallurgical Recovery |

% |

73.3% |

|

Ore Reserves Production Scenario |

years |

25 |

|

Annual LCE Mined |

k-tonnes |

95.4 |

1.17 Conclusions and Recommendations

1.17.1 Conclusions

Based upon analysis, interpretation and results of exploration, engineering, and environmental permitting carried out for the Project the following conclusions have been made:

Mineral Resource Estimate: The mineralization is at surface and made up of a claystone and ash mix that can be free dug with minimal blasting while using conventional mining equipment. The Mineral Resource estimate was updated in 2022 to 534.7 Mt of Measured Resource averaging 2,450 ppm Li for 7.0 Mt of lithium carbonate equivalent, 922.5 Mt of Indicated Resource averaging 1,850 ppm Li for 9.1 Mt of lithium carbonate equivalent and 297.2 Mt of Inferred Resource averaging 1,870 ppm Li for 3.0 Mt lithium carbonate equivalent. This resulted in a 229% increase in tonnage and 130% more lithium carbonate equivalent. A cutoff grade of 1,047 ppm Li and an open pit shell were used to constrain the resource estimate based on break even economics.

Mineral Reserve Estimate: The Mineral Reserve estimate was estimated from a 40-year pit designed to satisfy ore delivery requirements. The overall average lithium content mined is 3,160 ppm from 3,180 ppm Li Proven and 3,010 ppm Li Probable. Total ore is 217.3 Mt, of which 192.9 Mt are Proven reserves and 24.4 Mt are Probable. As a result, the total Proven and Probable Reserves of lithium carbonate equivalent is 3.7 Mt from 3.3 Mt lithium carbonate equivalent Proven and 0.4 Mt of lithium carbonate equivalent Probable.

Environmental Permits: There are no identified issues that would prevent LAC from achieving all permits and authorizations required to commence construction and operation of the Project based on the data that has been collected to date. The BLM has approved the Plan of Operations and issued its ROD. In Q1 2022, NDEP issued the two final environmental permits required for construction. The Water Pollution Control Permit (WPCP) was issued by Nevada Division of Environmental Protection-Bureau of Mining, Regulation and Reclamation (NDEP-BMRR). LAC and NDEP discussed an initial WPCP where operations would not take place below the 4,840 feet above mean sea level elevation, which is fifteen (15) feet above the pre-mining regional water table until further evaluations are completed that show that mining below the water table will not degrade the waters of the state. The Class II Air Quality Operating Permit was issued by NDEP-BAPC.

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Metallurgical Processes: Metallurgical processes have been engineered from pilot testing, bench scale testing, and modeling to produce lithium carbonate using conventional unit operations arranged in a novel flowsheet. Phase 1 production capacity is designed for a nominal 40,000 t/y and an additional 40,000 t/y for Phase 2, for a combined designed nominal capacity rate of 80,000 t/y of lithium carbonate.

Water and Power: Water required for construction and production during Phase 1 is secured, in the amount of 3.5 Mm3 (2,850 acre-ft) per year. Power demand for Phase 1 and Phase 2 is engineered and the required import load of 52 MW is identified. Power is assumed to be imported from local utilities with infrastructure upgrades required before Phase 1 production begins.

Capital Requirements: Capital costs are based on Q1-Q3 2022 pricing. CAPEX spending for Phase 1 will begin three years before production begins and will include one acid plant, the necessary civil works and infrastructure to support Phase 1 production rates. Phase 2 capital spending will begin in year 4 through 7 and will add a second acid plant and duplicate the necessary processing facility equipment. Phase 1 will require $2,268 million in capital and Phase 2 will require $1,728 million for a combined capital total of $3,996 million. Sustaining capital and mine capital repayment over a 25-year mine life totals $628 million. Sustaining capital and mine capital repayment costs over 40 years total $1,510 million.

Operating Costs: Cost inputs into the model are from Q1-Q4 2022. Any investments in the Project to date are not amortized in the model. The average unit operating cost per tonne of lithium carbonate mined and produced is expected to be $7,198 for the 40-year LOM (base case) and $6,743 for the 25-year case.

Economic Results: Based on Q1-Q4 2022 capital and operating cost pricing, the economic analysis of the Project includes:

1.17.2 Recommendations

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

2 Introduction and Terms of Reference

This Technical Report was prepared at the request of Lithium Americas Corp., a company incorporated under the laws of British Columbia, Canada, trading under the symbol "LAC" on the Toronto Stock Exchange and the New York Stock Exchange with its corporate office at 300 - 900 West Hastings Street, Vancouver, British Columbia, Canada, V6C 1E5. Work was carried out in cooperation with Lithium Nevada Corp. (LNC), a wholly owned subsidiary of Lithium Americas Corp. (LAC), formerly known as Western Lithium USA Corp (WLC).

This document provides a summary of the feasibility study evaluation of LAC's Thacker Pass Project (the Project) and focuses on the Thacker Pass Deposit (the Deposit), formerly Stage I of the Kings Valley Project or Lithium Nevada Project. Excluded from this Technical Report are resource statements from the Montana Mountains deposit (formerly Stage II deposit of the Lithium Nevada Project), as LAC's focus is on developing a project of scale in Thacker Pass. The claims owned by LAC that are north of the Thacker Pass Project in the Montana Mountains do not form part of this mineral project.

This report was prepared in the format stipulated by National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) applicable in Canada. Mineral Resources and Mineral Reserves estimation is based on the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) 2019 Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (2019 CIM Guidelines). Definitions of Mineral Resources and Mineral Reserves are as set out in the 2014 CIM Definition Standards for Mineral Resources and Mineral Reserves.

2.1 Sources of Information

M3 Engineering & Technology Corporation (M3) was commissioned by LAC to prepare this Technical Report. In preparing this report, M3 and Industrial TurnAround Corporation (ITAC) provided engineering services and have relied upon input from LAC and information prepared by a number of qualified independent consulting groups particularly regarding regional geology, geological mapping, exploration, and resource estimation. Through its subsidiary LNC, LAC has contracted with Sawtooth, a subsidiary of The North American Coal Corporation (NAC), which is a wholly-owned subsidiary of NACCO Industries, Inc. (NYSE: NC), to provide resource and reserve estimation for this technical report. NAC has reviewed and signed off on the work provided by Sawtooth. EXP U.S. Services Inc. (EXP) reviewed the sulfuric acid plant and power plant. NewFields Mining Design & Technical Services (NewFields) contributed to work on environmental and tailings facilities. Wood Canada Limited (Wood) reviewed segments of metallurgy and the process as well as environmental concerns. EDG, Inc. (EDG) participated in the preparation of some cost elements of the estimate.

M3, Sawtooth, NACCO, NewFields, Wood, EXP and Piteau are independent companies and not associates or affiliates of LAC or any associated company of LAC. Table 2-1 lists the Qualified Persons (QP) involved with authoring this report. Table 2-2 lists the sections each QP is responsible for.

Table 2-1 List of Qualified Persons, Professional Designations and Site Visit Dates

|

Name of Qualified |

Designation |

Company |

Date of Site Visit |

|

Daniel Roth |

P.E., P. Eng. |

M3 |

April 13, 2021 |

|

Laurie Tahija |

QP-MMSA |

M3 |

No site visit |

|

Benson Chow |

RM-SME |

Sawtooth |

November 8, 2018, September 13 and 14, 2022 |

|

Eugenio Iasillo |

P.E. |

Process Engineering, LLC |

No site visit: Reno Laboratory Visit Only |

|

Kevin Martina |

P. Eng. |

Wood |

No site visit: Reno Laboratory Visit Only (December 1-3, 2021) |

|

Kevin Bahe |

P.E. |

Sawtooth |

August 12 & 13, 2019, September 13 & 14, 2022 |

|

Walter Mutler |

P. Eng. |

EXP U.S. Services Inc. |

November 2, 2022 |

|

Paul Kaplan |

P.E. |

NewFields |

No site visit |

|

Tyler Cluff |

RM-SME |

Piteau |

March 7-8, June 8, and November 7-9, 2022 |

|

Bruce Shannon |

P.E. |

ITAC |

October 18, 2020 |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

Table 2-2 Qualified Person Areas of Responsibility

|

Section |

Section Name |

Qualified |

Description of |

Subsections |

|

1 |

Summary |

All QPs |

- |

- |

|

2 |

Introduction |

Daniel Roth |

- |

- |

|

3 |

Reliance on other Experts |

Daniel Roth |

- |

- |

|

4 |

Property Description and Location |

Benson Chow |

- |

- |

|

5 |

Accessibility, Climate, Local Resources, Infrastructure and Physiography |

Benson Chow |

- |

- |

|

6 |

History |

Benson Chow |

- |

- |

|

7 |

Geological Setting and Mineralization |

Benson Chow |

- |

- |

|

8 |

Deposit Types |

Benson Chow |

- |

- |

|

9 |

Exploration |

Benson Chow |

- |

- |

|

10 |

Drilling |

Benson Chow |

- |

- |

|

11 |

Sample Preparation, Analyses and Security |

Benson Chow |

- |

- |

|

12 |

Data Verification |

Benson Chow |

- |

- |

|

13 |

Mineral Processing and Metallurgical Testing |

Eugenio Iasillo |

ROM feed through neutralized tails as well as magnesium precipitation |

All except for Sections 13.2.4.1, 13.2.4.3, 13.2.5.1 to 13.2.5.3 |

|

|

|

Kevin Martina |

Magnesium sulfate crystallization to production of final product, excluding magnesium precipitation. |

13.2.4.1, 13.2.4.3, 13.2.5.1 to 13.2.5.3 |

|

14 |

Mineral Resource Estimates |

Benson Chow |

- |

- |

|

15 |

Mineral Reserve Estimates |

Kevin Bahe |

- |

- |

|

16 |

Mining Methods |

Kevin Bahe |

- |

- |

|

17 |

Recovery Methods |

Laurie Tahija |

ROM feed through neutralized tails as well as magnesium precipitation. |

Section 17.1, Tables 17-1 and 17-3 and corresponding parts of 17.2.1 in Section 17.2, 17.3.1 to 17.3.4, 17.3.5.2, 17.3.8, 17.4.1 to 17.4.3, 17.4.6, corresponding parts of 17.4.10 and 17.4.11, and 17.5 to 17.11. |

| Lithium Americas Corp. Feasibility Study, National Instrument 43-101 Technical Report for the Thacker Pass Project, Humboldt County, Nevada, USA |

|

Section |

Section Name |

Qualified |

Description of |

Subsections |

|

|

|

Kevin Martina |

Magnesium sulfate crystallization to packaging of final product, excluding magnesium precipitation |

Tables 17-2 and 17-4 and corresponding parts of 17.2.1 in Section 17.2, Sections 17.3.5.1, 17.3.6, 17.3.7, 17.4.4, 17.4.5, 17.4.7, 17.4.8, 17.4.9 and corresponding parts of 17.4.10 and 17.4.11. |

|

18 |

Project Infrastructure |

Daniel Roth |

Access, water supply, site & process plant arrangement |

18.1, 18.2, 18.3, 18.4, 18.5, 18.6, and 18.9 |

|

|

|

Bruce Shannon |

Power supply |

18.7 |

|

|

|

Walter Mutler |

Sulfuric acid production |

18.8 |

|

|

|

Paul Kaplan |

Waste rock and tailing disposal |

18.10 |

|

19 |

Market Studies and Contracts |

Daniel Roth |

- |

- |

|

20 |

Environmental Studies, Permitting and Social or Community Impact |

Paul Kaplan |

General environmental and permitting |

All except for 20.7.4.1 to 20.7.4.6 |

|

|

|

Tyler Cluff |

Water |

Sections 20.7.4.1-20.7.4.6 |

|

21 |

Capital and Operating Costs |

Daniel Roth |

Process and infrastructure capital costs |

All except for 21.1.3, 21.2.1 and 21.3. |

|

|

|

Laurie Tahija |

Process operating costs |

Section 21.3 except 21.3.3.1 and 21.3.3.3 |

|

|

|

Kevin Bahe |

Mining costs |

21.1.3, 21.2.1, 21.3.3.1 |

|

|

|

Walter Mutler |

Sulfuric acid plant costs |

21.2.1, 21.3.3.3 |

|

22 |

Economic Analysis |

Daniel Roth |

- |

- |

|

23 |

Adjacent Properties |

Benson Chow |

- |

- |

|

24 |

Other Relevant Data and Information |

Daniel Roth |

Project Execution Plan |

24.1 |

|

|

|

Kevin Bahe |

Limestone Quarry |

24.2.1 to 24.2.4 |

|

|

|

Paul Kaplan |

Limestone Quarry Permitting |

24.2.5, 24.2.6 |

|

|

|

Daniel Roth |

Transload Facility |

24.3.1, 24.3.2 |

|

|

|

Paul Kaplan |

Transload Facility Permitting |

24.3.3 |

|

25 |

Interpretation and Conclusions |

All QPs |

- |

- |

|

26 |

Recommendations |

All QPs |

- |

- |

|

27 |

References |

N/A |

- |

- |

The Mineral Resource estimate is based on an exploration drilling program conducted in 2007 - 2010 and 2017 - 2018. Prior versions of the Mineral Resource were reported in previously filed technical reports as shown in Table 2-3.

Table 2-3 Previously Filed Technical Reports

|

Preparer |

Issuer |

Title |

Effective Date |

|

AMEC |

Western Lithium Corporation |