UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

______________________________________________________________________________________

FORM 10-K

ý ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2017

or

o TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from _____ to _____

Commission file number 1-13953

W. R. GRACE & CO.

(Exact name of registrant as specified in its charter)

|

| | |

Delaware | | 65-0773649 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

7500 Grace Drive, Columbia, Maryland 21044-4098

(Address of principal executive offices) (Zip code)

(410) 531-4000

(Registrant's telephone number, including area code)

|

| | |

Securities registered pursuant to Section 12(b) of the Exchange Act: |

Title of each class | | Name of each exchange on which registered |

Common Stock, $.01 par value per share | | New York Stock Exchange, Inc. |

Preferred Stock Purchase Rights | | |

| | |

Securities registered pursuant to Section 12(g) of the Exchange Act: |

None |

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ý No o

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes o No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulations S-K is not contained herein and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or an emerging growth company. See the definitions of "large accelerated filer," "accelerated filer," "smaller reporting company," and "emerging growth company" in Rule 12b-2 of the Exchange Act.

|

| | |

Large accelerated filer ý | | Accelerated filer o |

Non-accelerated filer o (Do not check if a smaller reporting company) | | Smaller reporting company o |

Emerging growth company o | | |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. o

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No ý

The aggregate market value of W. R. Grace & Co. voting and non-voting common equity held by non-affiliates as of June 30, 2017 (the last business day of the registrant's most recently completed second fiscal quarter) based on the closing sale price of $72.01 as reported on the New York Stock Exchange was $4,876,308,803.

Indicate by check mark whether the registrant has filed all documents and reports required to be filed by Section 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court. Yes ý No o

At January 31, 2018, 67,693,241 shares of W. R. Grace & Co. Common Stock, $.01 par value per share, were outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the definitive Proxy Statement to be delivered to our stockholders in connection with the Annual Meeting of Stockholders to be held on May 9, 2018, are incorporated by reference into Part III.

TABLE OF CONTENTS

|

| | |

PART I | | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

PART II | | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

PART III | | |

| | |

| | |

| | |

| | |

| | |

PART IV | | |

| | |

| | |

| |

GRACE®, the GRACE® logo and, except as otherwise indicated, the other trademarks, service marks or trade names used in the text of this Report are trademarks, service marks or trade names of operating units of W. R. Grace & Co. or its subsidiaries and/or affiliates. RESPONSIBLE CARE® is a trademark, registered in the United States and/or other countries, of the American Chemistry Council. UNIPOL® is a trademark of The Dow Chemical Company or an affiliated company of Dow. W. R. Grace & Co.–Conn. and/or its affiliates are licensed to use the UNIPOL® trademark in the area of polypropylene.

Unless the context indicates otherwise, in this Report the terms "Grace," "we," "us," or "our" mean W. R. Grace & Co. and/or its consolidated subsidiaries and affiliates, and the term the "Company" means W. R. Grace & Co. Unless otherwise indicated, the contents of websites mentioned in this report are not incorporated by reference or otherwise made a part of this Report.

The Financial Accounting Standards Board® is referred to in this Report as the "FASB." The FASB issues, among other things, the FASB Accounting Standards Codification® ("ASC") and Accounting Standards Updates ("ASU"). The U.S. Internal Revenue Service is referred to in this Report as the "IRS."

PART I

Item 1. BUSINESS

BUSINESS OVERVIEW

W. R. Grace & Co. is engaged in the production and sale of specialty chemicals and specialty materials on a global basis through two reportable business segments: Grace Catalysts Technologies, which includes catalysts and related products and technologies used in refining, petrochemical and other chemical manufacturing applications; and Grace Materials Technologies, which includes specialty materials, including silica-based and silica-alumina-based materials, used in coatings, consumer, industrial, and pharmaceutical applications. We entered the specialty chemicals industry in 1954, the year in which we acquired the Davison Chemical Company. Grace is the successor to a company that began in 1854 and originally became a public company in 1953. W. R. Grace & Co. is a Delaware corporation. Our principal executive offices are located at 7500 Grace Drive, Columbia, Maryland 21044; website is at www.grace.com; and telephone is +1 410.531.4000. As of December 31, 2017, we had approximately 3,700 global employees.

On January 27, 2016, Grace entered into a separation agreement with GCP Applied Technologies Inc., then a wholly-owned subsidiary of Grace ("GCP"), pursuant to which Grace agreed to transfer its Grace Construction Products operating segment and the packaging technologies business of its Grace Materials Technologies operating segment to GCP (the "Separation"). Grace and GCP completed the Separation on February 3, 2016 (the "Distribution Date"), by means of a pro rata distribution to the Company's stockholders of all of the outstanding shares of GCP common stock (the "Distribution"), with one share of GCP common stock distributed for each share of Company common stock held as of the close of business on January 27, 2016. As a result of the Distribution, GCP became an independent public company. GCP’s historical financial results through the Distribution Date are reflected in Grace’s Consolidated Financial Statements as discontinued operations.

On June 30, 2016, we completed the acquisition of the assets of the BASF Polyolefin Catalysts business (the "polyolefin catalysts acquisition"), which included technologies, patents, trademarks, and production plants in Pasadena, Texas, and Tarragona, Spain, for a purchase price of $250.6 million. We added the following technologies to our catalysts portfolio: (1) LYNX® high-activity polyethylene ("PE") catalyst technologies used commercially in slurry processes for the production of high-density PE resins such as bimodal film and pipe, and (2) LYNX® polypropylene ("PP") catalyst technologies used commercially in all major PP process technologies including slurry, bulk loop, stirred gas, fluid gas, and stirred bulk. The acquisition also provided us with significant additional flexibility and capacity for our global polyolefin catalysts manufacturing network.

In 2016, we exited certain Grace Materials Technologies product lines, as these product lines no longer fit into our strategic growth plans. We sold certain of these assets to unaffiliated buyers for aggregate proceeds of $12.9 million.

On February 3, 2014, Grace concluded a voluntary reorganization under Chapter 11 of the United States Bankruptcy Code in the United States Bankruptcy Court for the District of Delaware, when the joint plan of reorganization (the "Joint Plan") filed by Grace and certain other parties became effective.

On December 14, 2017, we signed a definitive agreement to acquire the polyolefin catalysts business of Albemarle Corporation for $416 million, subject to regulatory approvals and other customary closing conditions. This acquisition would be complementary to our Specialty Catalysts business and would strengthen our catalysts technology portfolio, commercial relationships, and manufacturing network.

Grace Catalysts Technologies produces and sells catalysts and related products and technologies used in refining, petrochemical and other chemical manufacturing applications, as follows:

| |

• | Fluid catalytic cracking catalysts - also called FCC catalysts, that help to "crack" the hydrocarbon chain in distilled crude oil to produce transportation fuels, such as gasoline and diesel fuels, and other petroleum-based products; FCC additives used to reduce sulfur in gasoline, maximize propylene production from refinery FCC units, and reduce emissions of sulfur oxides, nitrogen oxides and carbon monoxide from refinery FCC units; and Methanol-to-Olefins (MTO) catalysts, used to convert methanol, often derived from coal, into petrochemical feeds such as ethylene and propylene. |

| |

• | Hydroprocessing catalysts (HPC) - most of which are marketed through our Advanced Refining Technologies LLC, or ART, joint venture with Chevron Products Company ("Chevron"), that are used in process reactors to upgrade heavy oils into lighter, more useful products that comply with rising environmental standards by removing impurities such as nitrogen, sulfur and heavy metals, allowing less expensive feedstocks to be used in the petroleum refining process. (We hold a 50% economic interest in ART, which is not consolidated in our financial statements so ART's sales are excluded from our sales.) |

| |

• | Polyolefin catalysts and catalyst supports - also called specialty catalysts (SC), for the production of polypropylene and polyethylene thermoplastic resins, which can be customized to enhance the performance of a wide range of industrial and consumer end-use applications including high pressure pipe, geomembranes, food packaging, automotive parts, medical devices, and textiles; chemical catalysts used in a variety of industrial, environmental and consumer applications. |

| |

• | Gas-phase polypropylene process technology - which provides our licensees with a cost-effective, flexible, and reliable capability to manufacture polypropylene products across a wide spectrum of performance attributes enabling customers to manufacture products for a broad array of end-use applications. |

Grace Materials Technologies produces and sells specialty materials, including silica-based and silica-alumina-based materials, used in coatings, consumer, industrial, and pharmaceutical applications, as follows:

| |

• | Coatings - functional additives for wood and architectural coatings that provide surface effects and corrosion protection for metal substrates. |

| |

• | Consumer/Pharma - specialized materials used as additives and intermediates for pharmaceuticals, nutraceuticals, beer, toothpaste, food and cosmetic segments. |

| |

• | Chemical process - functional materials for use in plastics, rubber, tire, metal casting and adsorbent products for petrochemical and natural gas applications. |

Global Scope

We operate our business on a global scale with approximately 75% of our 2017 sales outside the United States. We operate and/or sell to customers in over 60 countries and in over 30 currencies. We manage our operating segments on a global basis, to serve global markets. Currency fluctuations affect our reported results of operations, cash flows, and financial position.

Strategy Overview

Our strategy is to capture growth opportunities arising primarily from global macro trends, including the rising standards of living and expanding middle class in developing regions, and increasingly stringent environmental standards and regulations. We strive to increase enterprise value by profitably growing our specialty chemicals and specialty materials businesses in the global marketplace and achieving high levels of efficiency and cash flow. To meet these objectives, we plan to:

| |

• | invest in research and development activities, with the goal of introducing new high-performance, technically differentiated products and services and enhancing manufacturing processes and operations; |

| |

• | expand sales and manufacturing into emerging regions, including China, India, other economies in Asia, Eastern Europe, the Middle East and Latin America; |

| |

• | pursue selected acquisitions and alliances that complement our current product offerings or provide opportunities for faster penetration of desirable market or geographic segments; |

| |

• | continue our commitment to manufacturing excellence, including process and productivity improvements, quality and cost-management; rigorous controls on working capital and capital spending; and the integration of our operations and supply chain management; and |

| |

• | invest in commercial excellence, which includes among other things, demonstrating the financial value of our products to the operations and end markets of our customers, managing our business development pipeline, and supporting our channel partners. |

PRODUCTS AND MARKETS

Specialty Chemicals and Materials Industry Overview

Specialty chemicals and specialty materials are high value-added products used as catalysts, intermediates, components, protectants or additives in a wide variety of products and applications. They are generally produced in relatively small volumes (compared with commodity chemicals) and must satisfy well-defined performance requirements and specifications. Specialty chemicals and specialty materials are often critical components of end products, catalysts for the production of end products, and components used in end products. Consequently, they are tailored to meet customer needs, which generally results in close relationships with our customers.

We focus our business on the following, which we believe are important competitive factors in the specialty chemicals and specialty materials industry:

| |

• | value-added products, technologies and services, sold at competitive prices; |

| |

• | customer service, including rapid response to changing customer needs; |

| |

• | technological leadership (resulting from investment in research and development and technical customer service); and |

| |

• | quality and reliability of product and supply. |

We believe that our focus on these competitive factors enables us to deliver significant value to customers at competitive prices and operating margins notwithstanding the increased customer service and research and development costs that this commitment entails.

Grace Catalysts Technologies Reportable Segment

Catalysts Technologies principally applies alumina, zeolite and inorganic support technologies in the design and manufacture of products with the goal of creating significant value for our diverse customer base. Our customers include major oil refiners as well as plastics and chemicals manufacturers. We believe that our technological expertise provides a competitive advantage, allowing us to quickly design products that help our customers create value in their operations and their end markets.

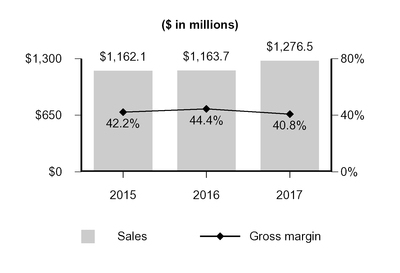

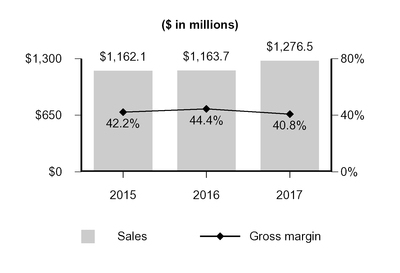

The following table sets forth Catalysts Technologies sales of similar products, technologies, and services as a percentage of Grace total revenue.

|

| | | | | | | | | | | | | | | | | | | | |

| 2017 | | 2016 | | 2015 |

(In millions) | Sales | | % of Grace Revenue | | Sales | | % of Grace Revenue | | Sales | | % of Grace Revenue |

Refining catalysts | $ | 758.1 |

| | 44.2 | % | | $ | 724.9 |

| | 45.3 | % | | $ | 764.5 |

| | 47.0 | % |

Polyolefin and chemical catalysts | 518.4 |

| | 30.2 | % | | 438.8 |

| | 27.5 | % | | 397.6 |

| | 24.4 | % |

Total Catalysts Technologies Revenue | $ | 1,276.5 |

| | 74.4 | % | | $ | 1,163.7 |

| | 72.8 | % | | $ | 1,162.1 |

| | 71.4 | % |

The following table sets forth Catalysts Technologies sales by region as a percentage of Catalysts Technologies total revenue.

|

| | | | | | | | | | | | | | | | | | | | |

| 2017 | | 2016 | | 2015 |

(In millions) | Sales | | % of Catalysts Technologies Revenue | | Sales | | % of Catalysts Technologies Revenue | | Sales | | % of Catalysts Technologies Revenue |

North America | $ | 386.9 |

| | 30.3 | % | | $ | 386.2 |

| | 33.2 | % | | $ | 375.9 |

| | 32.4 | % |

Europe Middle East Africa | 454.5 |

| | 35.6 | % | | 438.8 |

| | 37.7 | % | | 402.5 |

| | 34.6 | % |

Asia Pacific | 365.7 |

| | 28.7 | % | | 261.1 |

| | 22.4 | % | | 293.0 |

| | 25.2 | % |

Latin America | 69.4 |

| | 5.4 | % | | 77.6 |

| | 6.7 | % | | 90.7 |

| | 7.8 | % |

Total Catalysts Technologies Revenue | $ | 1,276.5 |

| | 100.0 | % | | $ | 1,163.7 |

| | 100.0 | % | | $ | 1,162.1 |

| | 100.0 | % |

Grace Catalysts Technologies—Refining Catalysts

FCC Catalysts

We are a global leader in developing and manufacturing fluid catalytic cracking, or FCC, catalysts and additives that are designed to enable petroleum refiners to increase profits by improving product yields, value and quality. Our FCC products also enable refiners to reduce emissions from their FCC units and reduce sulfur content in the transportation fuels they produce. Oil refining is a highly specialized discipline and FCC catalysts must be tailored to meet local variations in crude oil feedstocks and a refinery's product mix. We work regularly with our customers to identify the most appropriate catalyst and additive formulations for their changing needs.

Since our customers are refiners, our business is highly dependent on the economics of the petroleum refining industry. In particular, demand for our FCC products is affected by refinery throughput, the type and quality of refinery feedstocks, and the demand for transportation fuels and other refinery products, for example petrochemical feeds such as propylene.

In general, as a refinery utilizes more of its FCC unit capacity, it needs a greater amount of FCC catalyst. Refinery throughput, or the extent to which refiners utilize their available FCC capacity, is generally determined by demand for transportation fuels and petrochemical products and the availability of crude oil supply. In recent years, global economic growth, especially in emerging regions, has increased global demand for transportation fuels and petrochemical products. Retail gasoline and diesel fuel prices and the level of economic activity has also directly influenced transportation fuel demand. Improvements in vehicular fuel economy, as well as consumer trends and government policies that increase the use of non-petroleum-based fuels and/or decrease the use of petroleum-based fuels also will affect transportation fuel demand over time.

Refinery crude oil feedstocks vary in quality from light and sweet to heavy and sour. Light and sweet feedstocks are typically more expensive than heavy and sour feedstocks and yield a greater proportion of high-value petroleum products. They also yield a lower proportion of residual oil, or "resid," which is generally the lowest value component contained in crude oil. Although heavy and sour feedstocks with high resid content are typically less expensive than higher quality feedstocks, the processing of high-resid feedstocks is more difficult because these feedstocks have more impurities and higher boiling points. Heavy and sour crude oil has a relatively high level of metals, nitrogen and sulfur contamination. Our customers generally determine the feedstocks to be used in their refineries based on relative pricing and availability of various quality feedstocks. Refinery configuration and complexity also plays a role in feedstock selection; more complex refineries tend to process a higher proportion of heavy and sour feedstocks. In general, as a refinery uses more heavy and sour feedstocks, it uses a greater amount of FCC catalyst. In addition, refiners use special high value-added formulations of FCC catalysts for efficient refining of heavy and sour feedstocks. We have designed our MIDAS® catalyst, IMPACT® catalyst, NEKTOR™ catalyst, and GENESIS® catalyst product portfolios to enable our customers to increase the efficiency and yield of high-resid feedstock refining.

Many countries and regions, including the U.S., European Union, Japan, Russia, India and China have imposed regulatory limitations on the sulfur content of gasoline and diesel fuel. We have developed a portfolio of products designed to assist refiners in meeting their gasoline sulfur-reduction targets, including our D-PRISM® and GSR® additives and our SURCA® catalyst family.

Within certain limits, refiners have the ability to adjust their relative output of transportation fuels versus petrochemical feeds. Global economic growth, especially in emerging regions, has increased the demand for plastics at a faster rate than growth of transportation fuels. As a result, some of our refinery customers have sought increased profits from petrochemicals by increasing the yield of petrochemical feeds such as propylene from their FCC units. Our ZSM-5-based technologies, including our OLEFINSULTRA® additive products, are designed to maximize the propylene and butylene output of FCC units.

Many U.S. petroleum refiners have entered into consent decrees with the U.S. Environmental Protection Agency (the "EPA") under which the refiners have agreed to reduce emissions of nitrogen oxides and sulfur oxides. The European Union has also imposed requirements on refineries with respect to nitrogen oxides and sulfur oxides emissions. FCC units are generally the largest emitters of these pollutants in a refinery. Our additives are designed to assist refineries in meeting their obligations to reduce these pollutants. Our Super DESOX® additive reduces sulfur oxides emissions from commercial FCC units. Our DENOX® additives are designed to achieve reductions in nitrogen oxides emissions comparable to those obtained from capital intensive alternatives available to a refinery, while our non-platinum-based combustion promoters XNOX® and CP®P are designed to enable refiners to control carbon monoxide emissions without increasing nitrogen oxides.

Competition in FCC catalysts and additives is based on value delivered to refiners, which is derived from differentiated technology, catalyst performance, technical and customer service and price. Our principal global FCC catalyst competitors are Albemarle, BASF, and SINOPEC. Our principal global competitors in FCC additives are Johnson Matthey, Albemarle, and BASF. We also have multiple regional competitors for FCC catalysts and additives.

An emerging market is developing for the conversion of methanol, either derived from coal gasification or from natural gas, into petrochemical feeds such as ethylene and propylene. This technology, known as Methanol-to-Olefins, or MTO, has created the need for an FCC-like catalyst for use in this processing unit. A number of MTO units have been constructed and are operating in China, with additional units in the planning and construction phases. Our MTO catalyst, GCQ™, was introduced in 2016 and has been used successfully in a number of customer MTO units. Competition is based on catalyst performance, technical service and price. Our primary competitors are UOP and Chia Tai.

Hydroprocessing Catalysts

We market hydroprocessing catalysts primarily through ART, our joint venture with Chevron. We established ART to combine our technology with that of Chevron and to develop, market and sell hydroprocessing catalysts to customers in the petroleum refining industry worldwide.

We are a leading supplier of hydroprocessing catalysts designed for processing high resid content feedstocks. We offer products for fixed-bed resid hydrotreating, on-stream catalyst replacement and ebullating-bed resid hydrocracking processes.

We also offer a full line of catalysts, customized for individual refiners, used in distillate hydrotreating to produce ultra-low sulfur content gasoline and diesel fuel, including our SMART CATALYST SYSTEM® and APART® catalyst systems. As discussed above, regulatory limitations on the sulfur content of gasoline and diesel fuel are becoming more common. These products are designed to help refiners to reduce the sulfur content of their products.

We have rights to sell hydrocracking and lubes hydroprocessing catalysts to licensees of Chevron Lummus Global (CLG) and other petroleum refiners for unit refills. These rights allow us to streamline hydroprocessing catalyst supply and improve technical service for refining customers by establishing ART as their single point of contact for all their hydroprocessing catalyst needs.

Competition in the hydroprocessing catalyst industry is based on value delivered to refiners, which is based on differentiated technology, catalyst performance, technical and customer service and price. Criterion, Albemarle, Haldor Topsoe, UOP and Axens are our leading global competitors in hydroprocessing catalysts. We also have multiple regional competitors.

Grace Catalysts Technologies—Polyolefin Catalysts, Catalyst Supports and Polypropylene Process Technology

We are a leading provider of catalyst systems and catalyst supports to the polyolefins industry for a variety of polyethylene and polypropylene process technologies. These types of catalysts are used for the manufacture of polyethylene and polypropylene thermoplastic resins used in differentiated products such as plastic film, high-performance plastic pipe, automobile parts, household appliances, household containers, medical instruments, and many other end uses.

We use a combination of proprietary catalyst and support technology and technology licensed from third parties to provide unique catalyst-based solutions to our customers and to provide a broad technology portfolio for enhancing collaboration opportunities with technology leaders.

Our MAGNAPORE® polymerization catalyst is used to produce high performance polyethylene in the slurry loop process for pipe and film applications. We offer our LYNX® catalysts systems for the production of high-density polyethylene resins, such as bimodal film and pipe, as well as commercial use for the production of polypropylene in all major process technologies including slurry, bulk loop, stirred gas, fluid gas, and stirred bulk. Our CONSISTA® 6th generation, non-phthalate catalysts are used to produce polypropylene resins that exhibit enhanced clarity, stiffness, and impact strength. Our POLYTRAK® polymerization catalyst is designed to achieve improved polypropylene performance, particularly for impact resistant applications such as automobile bumpers and household appliances.

Our standard and customized DAVICAT® catalysts offer a wide range of chemical and physical properties based on our material science technology for supported catalysts, polystyrene, herbicide, nutraceuticals and on-purpose olefins. Our RANEY® nickel, cobalt and copper hydrogenation and dehydrogenation catalysts are used for the synthesis of organic compounds for the fibers, polyurethanes, engineered plastics, pharmaceuticals, sweeteners and petroleum industries.

The polyolefin catalyst and supports industry is technology-intensive, and suppliers must provide products formulated to meet customer specifications. There are many manufacturers of polyolefin catalysts and supports including Univation, LyondellBasell, Albemarle and PQ, and most sell their products worldwide.

We are also a leading licensor of gas-phase polypropylene process technology to polypropylene manufacturers. Our UNIPOL® polypropylene technology is designed to have fewer moving parts and require less equipment than other competing technologies in order to reduce operating costs. This technology provides our licensees with a flexible and reliable capability to manufacture products for a broad array of end-use applications. The polypropylene process licensing industry is technology-intensive, and licensors must adapt the technology and the related licenses to meet individual customer needs. The major competing polypropylene process licensors are LyondellBasell and Lummus Novolen Technology.

Grace Catalysts Technologies—Manufacturing, Marketing and Raw Materials

Our Catalysts Technologies products are manufactured by a network of globally coordinated plants. Our integrated planning organization is responsible for the effective utilization of our manufacturing capabilities.

We use a global organization of technical professionals with extensive experience in refining processes, catalyst development, and catalyst applications to market our refining catalysts and additives. These professionals work to tailor our technology to the needs of each specific customer. We generally negotiate prices for our refining catalysts because our formulations are specific to the needs of each customer and each customer receives individual attention and technical service. We sell a significant portion of our hydroprocessing catalysts through multiple-year supply agreements with our geographically diverse customer base.

We use a global direct sales force for our polyolefin catalysts, supports and technologies and chemical catalysts that seeks to maintain close working relationships with our customers. These relationships enable us to cooperate with major polymer and chemical producers to develop catalyst technologies that complement their process or application developments. We have geographically distributed our sales and technical service professionals to make them responsive to the needs of our geographically diverse customers. We typically operate under long-term contracts with our customers.

Seasonality does not have a significant overall effect on our Catalysts Technologies reportable segment. However, sales of FCC catalysts tend to be lower in the first calendar quarter due to maintenance outages taken

prior to the shift in production by refineries from home heating oil for the winter season to gasoline production for the summer season. FCC catalysts and ebullating-bed hydroprocessing catalysts are consumed at a relatively steady rate and are replaced regularly. Fixed-bed hydroprocessing catalysts are consumed over a period of years and are replaced in bulk in an irregular pattern. Since our customers periodically shut down their refining processes to replace fixed-bed hydroprocessing catalysts in bulk, our hydroprocessing catalyst sales to any customer can vary substantially over the course of a year and between years based on that customer's catalyst replacement schedule.

The principal raw materials for Catalysts Technologies products include molybdenum oxide, zeolite, caustic soda, sodium aluminate, sodium silicate, aluminum sulfate, nickel, alumina hydrate, alumina, aluminum metal, rare earths, and tungsten salt. Multiple suppliers are generally available for each of these materials; however, some of our raw materials may be provided by single sources of supply. We seek to mitigate the risk of using single source suppliers by identifying and qualifying alternative suppliers or, for unique materials, by using alternative formulations from other suppliers or by passing price increases on to customers. In some instances, we produce our own raw materials and intermediates.

Prices for many of our raw materials, including metals, and energy can be volatile. In response to increases in raw material and energy costs, we generally take actions to mitigate the effect of higher costs including increasing prices, developing alternative formulations for our products, increasing productivity, and hedging purchases of certain raw materials.

As in many chemical businesses, we consume significant quantities of natural gas in the production of Catalysts Technologies products. World events and other economic factors cause volatility in the price of natural gas. Increases or decreases in the cost of natural gas and raw materials can have a significant impact on our operating margins. We have implemented a risk management program under which we hedge natural gas in a way that is designed to provide protection against price volatility.

Grace Materials Technologies Reportable Segment

Materials Technologies principally applies specialty silica, zeolite and fine chemical technologies in the design and manufacture of products to create significant value for our diverse customer base. Our customers include coatings manufacturers, consumer product manufacturers, plastics manufacturers, petrochemical and natural gas processors, and pharmaceutical companies. We believe that our technological expertise and broad technology platform provide a competitive advantage, allowing us to tailor our products to specific customer requirements and help them create value in their operations and end markets.

The following table sets forth Materials Technologies sales of similar products as a percentage of Grace total revenue.

|

| | | | | | | | | | | | | | | | | | | | |

| 2017 | | 2016 | | 2015 |

(In millions) | Sales | | % of Grace Revenue | | Sales | | % of Grace Revenue | | Sales | | % of Grace Revenue |

Coatings | $ | 142.2 |

| | 8.3 | % | | $ | 136.5 |

| | 8.5 | % | | $ | 133.6 |

| | 8.2 | % |

Consumer/Pharma | 123.3 |

| | 7.2 | % | | 121.9 |

| | 7.6 | % | | 125.1 |

| | 7.7 | % |

Chemical process | 153.5 |

| | 8.9 | % | | 142.6 |

| | 8.9 | % | | 137.0 |

| | 8.4 | % |

Other | 21.0 |

| | 1.2 | % | | 33.9 |

| | 2.2 | % | | 70.4 |

| | 4.3 | % |

Total Materials Technologies Revenue(1) | $ | 440.0 |

| | 25.6 | % | | $ | 434.9 |

| | 27.2 | % | | $ | 466.1 |

| | 28.6 | % |

___________________________________________________________________________________________________________________

| |

(1) | In 2016, we exited certain product lines that accounted for approximately $35 million of Materials Technologies sales in 2015. |

The following table sets forth Materials Technologies sales by region as a percentage of Materials Technologies total revenue.

|

| | | | | | | | | | | | | | | | | | | | |

| 2017 | | 2016 | | 2015 |

(In millions) | Sales | | % of Materials Technologies Revenue | | Sales | | % of Materials Technologies Revenue | | Sales | | % of Materials Technologies Revenue |

North America | $ | 99.1 |

| | 22.5 | % | | $ | 104.5 |

| | 24.0 | % | | $ | 114.1 |

| | 24.5 | % |

Europe Middle East Africa | 213.2 |

| | 48.5 | % | | 209.0 |

| | 48.1 | % | | 218.7 |

| | 46.9 | % |

Asia Pacific | 94.1 |

| | 21.4 | % | | 87.8 |

| | 20.2 | % | | 97.9 |

| | 21.0 | % |

Latin America | 33.6 |

| | 7.6 | % | | 33.6 |

| | 7.7 | % | | 35.4 |

| | 7.6 | % |

Total Materials Technologies Revenue | $ | 440.0 |

| | 100.0 | % |

| $ | 434.9 |

| | 100.0 | % | | $ | 466.1 |

| | 100.0 | % |

Grace Materials Technologies—Silica-based Products

We globally manufacture functional additives and process aids, such as silica gel, colloidal silica, zeolitic adsorbents, precipitated silica and silica-aluminas, for a wide variety of applications and end-use industries. We also custom manufacture fine chemical intermediates and regulatory starting materials used primarily in the pharmaceutical and nutritional supplements industries. Our product portfolio includes:

|

| | | | |

Application | | Use | | Key Brands |

Coatings | | Matting agents, anticorrosion pigments, TiO2 extenders and moisture scavengers for paints and lacquers | | SYLOID®, SHIELDEX®, SYLOSIV®, SYLOWHITE™ |

| | Additives for matte, semi-glossy and glossy ink receptive coatings on high performance ink jet papers, photo paper, and commercial wide-format print media | | SYLOJET®, DURAFILL®, LUDOX® |

| | Paper retention aids, functional fillers, paper frictionizers | | DURAFILL®, LUDOX® |

| | Defoamers | | ZEOFLO®, ZEOFOAM® |

Consumer/ Pharma | | Toothpaste abrasives and thickening agents | | SYLODENT®, SYLOBLANC®, SIDENT® |

| | Free-flow agents, anticaking agents, heating agents, tabletting aids, cosmetic additives and flavor carriers | | PERKASIL®, SYLOID®, SYLOSIV®, ZEOFLO® , ZEOFOAM® |

| | Edible oil refining agents, stabilizers and clarification aids for beer, juices and other beverages | | TRISYL®, DARACLAR® |

| | Pharmaceutical excipients and drug delivery | | SYLOID® FP, SYLOID® XDP, SILSOL® |

| | Fine chemical intermediates and regulatory starting materials | | SYNTHETECH™ |

| | Chromatography purification media | | DAVISIL®, VYDAC® |

Chemical Process | | Reinforcing agents for rubber and tires | | PERKASIL® |

| | Inorganic binders and surface smoothening aids for precision investment casting and refractory applications | | LUDOX® |

| | Static adsorbents for dual pane windows and refrigerant applications, moisture scavengers, and package desiccants | | PHONOSORB®, SYLOSIV®, CRYOSIV®, PROTEKSORB® |

| | Chemical metal polishing aids and formulations for chemical mechanical planarization/electronics applications | | POLIEDGE® |

| | Antiblocking additives for plastic films to prevent adhesion of layers in manufacturing | | SYLOBLOC® |

| | Process adsorbents used in petrochemical and natural gas processes for such applications as ethylene-cracked-gas-drying, natural gas drying and sulfur removal | | SYLOBEAD® |

Our materials are integrated into our customers' manufacturing processes and when combined with our technical support, can increase the efficiency and performance of their operations and their products. By working closely with our customers, we seek to help them respond quickly to changing consumer demands. In addition, we focus on developing and manufacturing products that differentiate our customers' products and help them

meet evolving regulatory and environmental requirements. For example, our coatings additives are designed to be used in more sustainable water-based and VOC-compliant coatings. Our pharmaceutical excipients help improve bioavailability, extend shelf-life, and/or make drug manufacturing more efficient. Our dental silicas are engineered to provide high cleaning with gentle abrasivity. Our beer stabilization silicas offer greater productivity to breweries while reducing solid waste and water usage. Our custom manufacturing of advanced intermediates supports pharmaceutical drug development processes, enabling commercialization of life-saving therapies.

Our products are used in a wide range of industries, including paint and coatings, pharmaceutical, food and beverage, personal care, plastics and rubber, and petrochemical and biofuels. We can modify the base silica and surface chemistry for our customers in order to enhance our product performance for their unique applications.

Our global footprint allows us to partner effectively with both multinational and regional companies requiring multiple manufacturing facilities complemented by regional technical expertise in local languages. There are many manufacturers of engineered materials that market their products on a global basis including Evonik, PQ, and UOP. Competition is generally based on product performance, technical service, quality and reliability, price, and other differentiated product features to address the needs of customers, end-users and brand owners. Our products compete on the basis of distinct technology, product quality, and customer support. Competition for these products is highly fragmented, with a large number of companies that sell their products on a global or regional basis.

Grace Materials Technologies—Manufacturing, Marketing and Raw Materials

Our Materials Technologies products are manufactured by a network of globally integrated plants that are positioned to service our customers regionally. Our integrated planning organization is responsible for the effective utilization of our manufacturing capabilities.

We use country-based direct sales forces that are dedicated to each product line and backed by application-specific technical customer service teams to market our Materials Technologies products. Our sales force seeks to develop long-term relationships with our customers and focuses on consultative sales, technical support and key account growth programs. To ensure full geographic coverage, our direct sales organization is further supplemented by a network of distributors and agents.

Seasonality does not have a significant overall effect on our Materials Technologies reportable segment; however, our adsorbents for dual frame windows are affected by seasonal and weather-related factors and the level of construction activity, and our edible oil refining agents, stabilizers and clarification aids for beer, juices and other beverages are affected by the level of consumption of beverages. These impacts are mitigated by the global scope of our business.

The principal raw materials for Materials Technologies products include sodium silicate, zeolite, soda ash, sulfuric acid, and caustic soda. Multiple suppliers are generally available for each of these materials; however, some of our raw materials may be provided by single sources of supply. We seek to mitigate the risk of using single source suppliers by identifying and qualifying alternative suppliers or, for unique materials, by using alternative formulations from other suppliers or by passing price increases on to customers. In some instances, we produce our own raw materials and intermediates.

Prices for many of our raw materials and energy can be volatile. In response to increases in raw material and energy costs, we generally take actions intended to mitigate the effect of higher costs including increasing prices, developing alternative formulations for our products, and increasing productivity.

As in many chemical businesses, we consume significant quantities of natural gas in the production of Materials Technologies products. World events and other economic factors can cause volatility in the price of natural gas. Increases or decreases in the cost of natural gas and raw materials can have a significant impact on our operating margins. We have implemented a risk management program under which we hedge natural gas in a way that is intended to provide protection against price volatility.

FINANCIAL INFORMATION ABOUT INDUSTRY SEGMENTS AND GEOGRAPHIC AREAS

Disclosure of financial information about industry segments and geographic areas for 2017, 2016 and 2015 is provided in this Report in Item 8 (Financial Statements and Supplementary Data) in the Financial Supplement under Note 17 (Segment Information) to the Consolidated Financial Statements, which disclosure is incorporated

herein by reference. Disclosure of risks attendant to our foreign operations is provided in this Report in Item 1A (Risk Factors), which disclosure is incorporated herein by reference.

BACKLOG OF ORDERS

While at any given time there may be some backlog of orders, this backlog is not material in respect to our total annual sales, nor are the changes, from time to time, significant.

INTELLECTUAL PROPERTY; RESEARCH ACTIVITIES

Competition in the specialty chemicals and specialty materials industry is often based on technological superiority and innovation. Our ability to maintain our margins and effectively compete with other suppliers depends on our ability to introduce new products based on innovative technology, as well as our ability to obtain patent or other intellectual property protection. Our research and development programs emphasize development of new products and processes, improvement of existing products and processes and application of existing products and processes to new industries and uses. Most research activity is conducted in North America and Europe.

We routinely file and obtain patents in a number of countries around the world that are significant to our businesses in order to protect our investments in innovation, research, and product development. Numerous patents and patent applications protect our products, formulations, manufacturing processes, equipment, and improvements. We also benefit from the use of trade secret information, including know-how and other proprietary information relating to many of our products and processing technologies. There can be no assurance, however, that our patents, patent applications and precautions to protect trade secrets and know-how will provide sufficient protection for our intellectual property. In addition, other companies may independently develop technology that could replicate, and thus diminish the advantage provided by, our trade secrets. Other companies may also develop alternative technology or design-arounds that could circumvent our patents or may acquire patent rights applicable to our business which might interpose a limitation on expansion of our business in the future.

Research and development expenses were approximately $54 million, $49 million, and $47 million in 2017, 2016, and 2015, respectively. These amounts include depreciation and amortization expenses related to research and development assets and expenses incurred in funding external research projects. The amount of research and development expenses relating to government- and customer-sponsored projects (rather than projects that we sponsor) was not material during these periods. Grace also conducts research and development activities with our ART joint venture, which are not included in the amounts above.

ENVIRONMENT, HEALTH AND SAFETY MATTERS

We are subject, along with other manufacturers of specialty chemicals, to stringent regulations under numerous regional, national, provincial, state and local environment, health and safety laws and regulations relating to the manufacture, storage, handling, disposal and stewardship of chemicals and other materials. Environmental laws require that certain responsible parties, as defined in the relevant statute, fund remediation actions regardless of legality of original disposal or ownership of a disposal site. We are involved in various response actions to address the presence of chemical substances as required by applicable laws.

We have expended substantial funds to comply with environmental laws and regulations and expect to continue to do so in the future. The following table sets forth our expenditures in the past three years, and our estimated expenditures in 2018 and 2019, for (i) the operation and maintenance of manufacturing facilities and the disposal of wastes; (ii) capital expenditures for environmental control facilities; and (iii) site remediation:

|

| | | | | | | | | | | |

(In millions) | Operation of Facilities and Waste Disposal | | Capital Expenditures | | Site Remediation |

2015 | $ | 47 |

| | $ | 15 |

| | $ | 12 |

|

2016 | 62 |

| | 10 |

| | 18 |

|

2017 | 51 |

| | 7 |

| | 20 |

|

2018(1) | 53 |

| | 19 |

| | 24 |

|

2019(1) | 55 |

| | 18 |

| | 13 |

|

| |

(1) | Amounts are based on environmental response matters for which sufficient information is available to estimate costs. We do not have sufficient information to estimate all of Grace's possible future environmental response costs. As we receive new information, our estimate of such costs may change materially. |

Additional information about our environmental remediation activities is provided in this Report in Item 8 (Financial Statements and Supplementary Data) in the Financial Supplement under Note 10 (Commitments and Contingent Liabilities) to the Consolidated Financial Statements, which information is incorporated herein by reference.

We continuously seek to improve our environment, health and safety performance. To the extent applicable, we extend the basic elements of the American Chemistry Council's RESPONSIBLE CARE® program to all our locations worldwide, embracing specific performance objectives in the key areas of management systems, product stewardship, employee health and safety, community awareness and emergency response, distribution, process safety and pollution prevention. We have implemented the RESPONSIBLE CARE® Security Code through a company-wide security program focused on the security of our people, processes, and systems. We have reviewed existing security (including cybersecurity) vulnerability and taken actions to enhance security systems where deemed necessary. In addition, we are complying with the Department of Homeland Security’s Chemical Facility Anti-Terrorism Standards, including identifying facilities subject to the standards, conducting security vulnerability assessments and developing site security plans, as necessary.

EMPLOYEE RELATIONS

As of December 31, 2017, we employed approximately 3,700 persons, of whom approximately 1,900 were employed in the United States and approximately 1,000 were employed in Germany. Of our total employees, approximately 2,200 were salaried and 1,500 were hourly.

Approximately 640 of our manufacturing employees in the United States are represented by unions. We have operated without a labor work stoppage for more than 10 years. We have works councils representing the majority of our European sites serving approximately 1,100 employees.

AVAILABILITY OF REPORTS AND OTHER DOCUMENTS

We maintain an Internet website at www.grace.com. Our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and amendments to those reports, filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended, are available, free of charge, on our website as soon as reasonably practicable after such reports are electronically filed with, or furnished to, the Securities and Exchange Commission, or SEC. These reports may be accessed through our website's investor information page.

In addition, the charters for the Audit, Compensation, Nominating and Governance, and Corporate Responsibility Committees of our Board of Directors, our corporate governance principles and code of ethics are available, free of charge, on our website at www.grace.com/en-us/corporate-leadership/pages/governance.aspx. Printed copies of the charters, governance principles and code of ethics may be obtained free of charge by contacting Grace Shareholder Services at 410-531-4167.

The information on our website is not, and shall not be deemed to be, a part of this report or incorporated into any other filings we make with the SEC.

Our Chief Executive Officer and Chief Financial Officer have submitted certifications to the SEC pursuant to the Sarbanes Oxley Act of 2002 as exhibits to this Report.

EXECUTIVE OFFICERS

See "Executive Officers of the Registrant" following Part I, Item 4 of this Report for information about our Executive Officers.

Item 1A. RISK FACTORS

This Report, including the Financial Supplement, contains, and our other public communications may contain, forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. All statements other than statements of historical fact, including statements regarding: expected financial positions; results of operations; cash flows; financing plans; business strategy; operating plans; capital and other expenditures; competitive positions; growth opportunities for existing products; benefits from new technology and cost reduction initiatives, plans and objectives; and markets for securities, are forward looking. Such statements generally include the words "believes," "plans," "intends," "targets," "will," "expects," "suggests," "anticipates," "outlook," "continues" or similar expressions. For these statements, we claim the protection of the safe harbor for forward-looking statements contained in Section 27A of the Securities Act and Section 21E of the Exchange Act. We are subject to risks and uncertainties that could cause our actual results to differ materially from our projections or that could cause other forward-looking statements to prove incorrect. Factors that could cause actual events to differ materially from those contained in the forward-looking statements include those factors set forth below and elsewhere in this Annual Report on Form 10-K. Our reported results should not be considered as an indication of our future performance. Readers are cautioned not to place undue reliance on our projections and forward-looking statements, which speak only as of the date those projections and statements are made. We undertake no obligation to publicly release any revisions to the projections and forward-looking statements contained in this document, or to update them to reflect events or circumstances occurring after the date of this document. In addition to general economic, business and market conditions, we are subject to other risks and uncertainties, including, without limitation, the following:

Risks Related to the Business

The global scope of our operations subjects us to the risks of doing business in foreign countries, which could adversely affect our business, financial condition and results of operations.

We operate our business on a global scale with approximately 75% of our 2017 sales outside the United States. We operate and/or sell to customers in over 60 countries and in over 30 currencies. We currently have many production facilities, research and development facilities and administrative and sales offices located outside North America, including facilities and offices located in EMEA (Europe Middle East Africa), Asia Pacific and Latin America. We expect non-U.S. sales to continue to represent a substantial majority of our revenue. Accordingly, our business is subject to risks related to the differing legal, political, social and regulatory requirements and economic conditions of many jurisdictions. Risks inherent in non-U.S. operations include the following:

| |

• | commercial agreements may be more difficult to enforce and receivables more difficult to collect; |

| |

• | intellectual property rights may be more difficult to enforce; |

| |

• | increased shipping costs, disruptions in shipping or reduced availability of freight transportation; |

| |

• | we may have difficulty transferring our profits or capital from foreign operations to other countries where such funds could be more profitably deployed; |

| |

• | we may experience unexpected adverse changes in export duties, quotas and tariffs and difficulties in obtaining export licenses; |

| |

• | some foreign countries have adopted, and others may impose, additional withholding and other taxes or adopt other restrictions on foreign trade or investment, including import, currency exchange and capital controls, charges and limitations; |

| |

• | foreign governments may nationalize private enterprises; |

| |

• | our business and profitability in a particular country could be affected by political or economic repercussions on a domestic, country-specific or global level from terrorist activities and the response to such activities; |

| |

• | we may be affected by unexpected adverse changes in foreign laws or regulatory requirements; |

| |

• | we may have to pay increased cash taxes in the event of a change in tax laws, regulations or interpretations in one or more foreign jurisdictions, and our business, financial condition or results of operations, or liquidity could be adversely affected; and |

| |

• | we are exposed to geopolitical risk, where unexpected changes in global, regional, or local political or social conditions could adversely affect our foreign operations. |

Our success as a global business will depend, in part, upon our ability to succeed in differing legal, regulatory, economic, social and political conditions by developing, implementing and maintaining policies and strategies that are effective in each location where we do business.

We are exposed to currency exchange rate changes that impact our profitability.

We are exposed to currency exchange rate risk through our U.S. and non-U.S. operations. Changes in currency exchange rates may materially affect our operating results. For example, changes in currency exchange rates may affect the relative prices at which we and our competitors sell products in the same region and the cost of materials used in our operations. A substantial portion of our net sales and assets are denominated in currencies other than the U.S. dollar, particularly the euro. When the U.S. dollar strengthens against other currencies, at a constant level of business, our reported sales, earnings, assets and liabilities are reduced because the non-U.S. currencies translate into fewer U.S. dollars.

We incur a currency transaction risk whenever one of our operating subsidiaries enters into either a purchase or a sales transaction using a currency different from the operating subsidiary's functional currency. Given the volatility of exchange rates, we may not be able to manage our currency transaction risks effectively, or volatility in currency exchange rates may expose our financial condition or results of operations to a significant additional risk.

Prices for certain raw materials and energy are volatile and can have a significant effect on our manufacturing and supply chain strategies as we seek to maximize our profitability. If we are unable to successfully adjust our strategies in response to volatile raw materials and energy prices, such volatility could have a negative effect on our earnings in future periods.

We use petroleum-based materials, metals, natural gas and other materials in the manufacture of our products. We consume substantial amounts of energy in our manufacturing processes. Prices for these materials and energy are volatile and can have a significant effect on our pricing, sales, manufacturing and supply chain strategies as we seek to maximize our profitability. Our ability to successfully adjust strategies in response to volatile raw material and energy prices is a significant factor in maintaining or improving our profitability. If we are unable to successfully adjust our strategies in response to volatile prices, such volatility could have a negative effect on our sales and earnings in future periods.

A substantial portion of our raw materials are commodities whose prices fluctuate as market supply and demand fundamentals change.

We attempt to manage exposure to price volatility of major commodities through:

| |

• | long-term supply contracts; |

| |

• | contracts with customers that permit adjustments for changes in prices of commodity-based materials and energy; |

| |

• | forward buying programs that layer in our expected requirements systematically over time; and |

| |

• | limited use of financial instruments. |

Although we regularly assess our exposure to raw material price volatility, we cannot always predict the prospects of volatility and we cannot always cover the risk in a cost effective manner.

We have a policy of maintaining, when available, multiple sources of supply for raw materials. However, certain of our raw materials may be provided by single sources of supply. We may not be able to obtain sufficient raw materials due to unforeseen developments that would cause an interruption in supply. Even if we have multiple sources of supply for raw materials, these sources may not make up for the loss of a major supplier.

If we are not able to continue our technological innovation and successful introduction of new products, our customers may turn to other suppliers to meet their requirements.

The specialty chemicals industry and the end-use markets into which we sell our products experience ongoing technological change and product improvements. A key element of our business strategy is to invest in research and development activities with the goal of introducing new high-performance, technically differentiated

products. We may not be successful in developing new technology and products that effectively compete with products introduced by our competitors, and our customers may not accept, or may have lower demand for, our new products. If we fail to keep pace with evolving technological innovations or fail to improve our products in response to our customers’ needs, then our business, financial condition and results of operations could be adversely affected as a result of reduced sales of our products.

We spend large amounts of money for environmental compliance in connection with our current and former operations.

As a manufacturer of specialty chemicals and specialty materials, we are subject to stringent regulations under numerous U.S. federal, state, local and foreign environmental, health and safety laws and regulations relating to the generation, storage, handling, discharge, disposition and stewardship of chemicals and other materials. We have expended substantial funds to comply with such laws and regulations and have established a policy to minimize our emissions to the environment. Nevertheless, legislative, regulatory and economic uncertainties (including existing and potential laws and regulations pertaining to climate change) make it difficult for us to project future spending for these purposes, and if there is an acceleration in new regulatory requirements, we may be required to expend substantial additional funds to remain in compliance.

We are subject to environmental clean-up costs, fines, penalties and damage claims that have been and continue to be costly.

In the U.S., we are subject to lawsuits and regulatory actions, in connection with current and former operations (including some divested businesses and off-site disposal facilities), that seek clean-up or other remedies. We are also subject to similar risks outside of the U.S.

We operated a vermiculite mine in Libby, Montana, until 1990. Some of the vermiculite ore that was mined at the Libby mine contained naturally occurring asbestos. We are cooperating with the U.S. Environmental Protection Agency and other federal, state and local governmental agencies in a remedial investigation and feasibility study ("RI/FS") of the Libby mine and the surrounding area to determine the location, scope and extent of required remediation. The EPA is also investigating or remediating formerly owned or operated sites that processed Libby vermiculite into finished products. We are cooperating with the EPA on these investigation and remediation activities, and have recorded a liability to the extent that our review has indicated that a probable liability has been incurred and the cost is estimable.

We have recorded liabilities for all environmental matters for which a loss is considered to be probable and sufficient information is available to reasonably estimate the loss. These liabilities do not include the cost to remediate the Libby vermiculite mine and surrounding area or costs related to any additional EPA claims, whether resulting from the EPA's investigation of vermiculite facilities or otherwise, which may be material but are not currently estimable. Due to these vermiculite-related matters, it is probable that our ultimate liability for environmental matters will exceed our current estimates by material amounts.

Our indebtedness may materially affect our business, including our ability to fulfill our obligations, react to changes in our business and incur additional debt to fund future needs.

We have a substantial amount of debt. As of December 31, 2017, we had $1,033.1 million of unsecured indebtedness outstanding and $510.8 million of secured indebtedness outstanding. Our indebtedness may have material effects on our business, including to:

| |

• | require us to dedicate a substantial portion of our cash flow to debt payments, thereby reducing funds available for working capital, capital expenditures, acquisitions, research and development, distributions to stockholders, stock repurchase programs and other purposes; |

| |

• | restrict us from making strategic acquisitions or taking advantage of favorable business opportunities; |

| |

• | limit our flexibility in planning for, or reacting to, changes in our business and the industries in which we operate; |

| |

• | increase our vulnerability to adverse economic, credit and industry conditions, including recessions; |

| |

• | make it more difficult for us to satisfy our debt service and other obligations; |

| |

• | place us at a competitive disadvantage compared to our competitors that have relatively less debt; and |

| |

• | limit our ability to borrow additional funds, or to dispose of assets to raise funds, if needed, for working capital, capital expenditures, acquisitions, research and development and other purposes. |

If we incur additional debt, the risks related to our indebtedness may intensify. We expect to incur additional debt in connection with the announced polyolefin catalysts acquisition.

Restrictions imposed by agreements governing our indebtedness may limit our ability to operate our business, finance our future operations or capital needs, or engage in other business activities. If we fail to comply with certain restrictions under these agreements, our debt could be accelerated and we may not have sufficient cash to pay our accelerated debt.

The agreements governing our indebtedness contain various covenants that limit, among other things, our ability, and the ability of certain of our subsidiaries, to:

| |

• | enter into sale and leaseback transactions; and |

| |

• | consolidate, merge or sell all or substantially all of our assets or the assets of our guarantors. |

As a result of these covenants, we will be limited in the manner in which we can conduct our business, and may be unable to engage in favorable business activities or finance future operations or capital needs. Accordingly, these restrictions may limit our flexibility to operate our business. A failure to comply with the restrictions contained in these agreements, including maintaining the financial ratios required by our credit facilities, could lead to an event of default which could result in an acceleration of our indebtedness. We cannot assure you that our future operating results will be sufficient to enable us to comply with the covenants contained in the agreements governing our indebtedness or to remedy any such default. In addition, in the event of an acceleration, we may not have or be able to obtain sufficient funds to make any accelerated payments.

Our indebtedness exposes us to interest expense increases if interest rates increase.

As of December 31, 2017, $301.3 million, or approximately 20%, of our borrowings were at variable interest rates and expose us to interest rate risk. If interest rates increase, our debt service obligations on the variable rate indebtedness would increase even though the amount borrowed would remain the same, and our net income would decrease. An increase of 100 basis points in the interest rates payable on our variable rate indebtedness would increase our annual estimated debt-service requirements by $3.0 million, assuming our consolidated variable interest rate indebtedness outstanding as of December 31, 2017, remains the same.

We have unfunded and underfunded pension plan liabilities. We will require future operating cash flow to fund these liabilities. We have no assurance that we will generate sufficient cash to satisfy these obligations.

We maintain U.S. and non-U.S. defined benefit pension plans covering current and former employees who meet or met age and service requirements. Our net pension liability and cost is materially affected by the discount rate used to measure pension obligations, the longevity and actuarial profile of our workforce, the level of plan assets available to fund those obligations and the actual and expected long-term rate of return on plan assets. Significant changes in investment performance or a change in the portfolio mix of invested assets can result in corresponding increases and decreases in the valuation of plan assets or in a change in the expected rate of return on plan assets. Assets available to fund the pension benefit obligation of the U.S. advance-funded pension plans at December 31, 2017, were approximately $1,110 million, or approximately $107 million less than the measured pension benefit obligation on a U.S. GAAP basis. In addition, any changes in the discount rate could result in a significant increase or decrease in the valuation of pension obligations, affecting the reported funded status of our pension plans as well as the net periodic pension cost in the following years. Similarly, changes in the expected return on plan assets can result in significant changes in the net periodic pension cost in the following years.

Our obligation to make payments to the PD Trust in respect of asbestos PD Claims (other than ZAI PD Claims) is not capped and we may be obligated to make additional payments.

Under the Joint Plan of reorganization that concluded Grace's status as a debtor under Chapter 11, as discussed above (the "Joint Plan"), an asbestos property damage trust has been established and funded under Section 524(g) of the Bankruptcy Code. The order of the Bankruptcy Court confirming the Joint Plan contains a channeling injunction which provides that all pending and future asbestos-related property damage claims and demands, PD Claims, can only be brought against the PD Trust. The PD Trust contains two accounts. One of these accounts, the PD Account, is funded solely in respect of PD Claims other than those PD Claims related to

our former ZAI attic insulation product. Unresolved and future non-ZAI PD Claims are to be litigated pursuant to procedures approved by the Bankruptcy Court and, to the extent such PD claims are determined to be allowed claims, are to be paid in cash by the PD Trust. We are obligated to make a payment to the PD Trust every six months in the amount of any non-ZAI PD Claims allowed during the preceding six months plus interest (if any) and the amount of PD Trust expenses for the preceding six months (the "PD Obligation"). The aggregate amount we are required to pay under the PD Obligation is not capped so we may have to make additional payments to the PD Account in respect of the PD Obligation. We are also obligated to make up to 10 contingent deferred payments to the PD Trust of $8 million each during the 20-year period beginning February 3, 2019, in respect of ZAI PD Claims in the event the ZAI PD Account's assets fall below $10 million in the preceding year. We have accrued liabilities for probable PD Claims but have not accrued any liability for the contingent ZAI PD payments as we do not currently believe they are probable.

Our ability to use net operating losses and tax credits to reduce future tax payments may be limited if there is a change in ownership of Grace or if Grace does not generate sufficient U.S. taxable income or foreign source income. Our ability to use these attributes is also subject to time limitations. Changes in tax laws and regulations may reduce their value and availability.

Our ability to use future tax deductions and tax credits, including net operating losses ("NOLs"), is dependent on our ability to generate sufficient future taxable income in the U.S. and sufficient foreign source income. Under U.S. federal income tax law, a corporation is generally permitted to carry forward NOLs for a 20-year period (indefinitely in the case of NOLs occurring in taxable years after December 31, 2017) for deduction against future taxable income. Federal tax credits may be carried forward for 10 years. Also, our ability to use NOLs and tax credits and their value may be adversely affected by changes in tax laws and regulations.

In addition, our ability to utilize federal and state NOLs and U.S. federal tax credits may be limited by Section 382 of the Internal Revenue Code resulting from future changes in the ownership of outstanding Company common stock. Our Amended and Restated Certificate of Incorporation provides that under certain circumstances, our Board of Directors would have the authority to impose restrictions on the transfer of Company common stock with respect to certain 5% stockholders in order to preserve these future tax benefits.

We intend to pursue acquisitions, joint ventures and other transactions that complement or expand our businesses. We may not be able to complete proposed transactions and even if completed, the transactions may involve a number of risks that may materially and adversely affect our business, financial condition and results of operations.

We intend to continue to pursue opportunities to buy other businesses or technologies that could complement, enhance or expand our current businesses or product lines or that might otherwise offer us growth opportunities. We may have difficulty identifying appropriate opportunities or, if we do identify opportunities, we may not be successful in completing transactions for a number of reasons. Any transactions that we are able to identify and complete may involve a number of risks, including:

| |

• | the diversion of management's attention from our existing businesses to integrate the operations and personnel of the acquired or combined business or joint venture; |

| |

• | possible adverse effects on our operating results during the integration process; |

| |

• | failure of the acquired business to achieve expected operational objectives; and |

| |

• | our possible inability to achieve the intended objectives of the transaction. |

In addition, we may not be able to successfully or profitably integrate, operate, maintain and manage any newly acquired operations or their employees. We may not be able to maintain uniform standards, controls, procedures and policies, which may lead to operational inefficiencies.

We work with dangerous materials that can injure our employees, damage our facilities, disrupt our operations, and contaminate the environment.

Some of our operations involve the handling of hazardous materials that may pose the risk of fire, explosion, or the release of hazardous substances. Such events could result from natural disasters, operational failures or terrorist attacks, and might cause injury or loss of life to our employees and others, environmental contamination, and property damage. These events might cause a temporary shutdown of an affected plant, or portion thereof, and we could be subject to penalties or claims as a result. A disruption of our operations caused by these or other events could have a material adverse effect on our results of operations.

Some of our employees are unionized, represented by works councils or employed subject to local laws that are less favorable to employers than the laws in the United States.

As of December 31, 2017, we had approximately 3,700 global employees. Approximately 640 of our approximately 1,900 U.S. employees are unionized. In addition, a large number of our employees are employed in countries in which employment laws provide greater bargaining or other rights to employees than the laws in the United States. Such employment rights require us to work collaboratively with the legal representatives of the employees to effect any changes to labor arrangements. For example, most of our employees in Europe are represented by works councils that have co-determination rights on any changes in conditions of employment, including certain salaries and benefits and staff changes, and may impede efforts to restructure our workforce. A strike, work stoppage or slowdown by our employees or significant dispute with our employees, whether or not related to these negotiations, could result in a significant disruption of our operations or higher ongoing labor costs.

We may be subject to claims of infringement of the intellectual property rights of others, which could hurt our business.